Plastic profile mixing workshop filter cylinder dust collector is a new type of filter dust removal device

Plastic profile mixing workshop filter cylinder dust collector is a new type of filter dust removal device, with high purification efficiency, small size, large filtering area, good filtering effect, small pressure loss, long service life of the filter cylinder, quick and convenient installation and maintenance, can be used continuously and so on. The cylinder dust collector is mainly designed for controlling a large number of dust particles harmful to human body produced in the production of machinery processing, chemical production, powder recovery, construction manufacturing, medical production, food processing, furniture production and hardware processing. Different combinations meet different air volume requirements, and can meet the multi-process dust collection and treatment in the production workshop. The collection methods include mobile suction arm type and fixed suction hood to minimize dust escape into the workshop and ensure the working environment of the workshop.

1. greatly improve the effective filtration area, reduce the footprint;

2. ensure a low and stable pressure difference, improve the flow of air;

3. the filter cylinder element is small, high filtration accuracy, easy to install;

4. It is especially suitable for industries with high dust concentration.

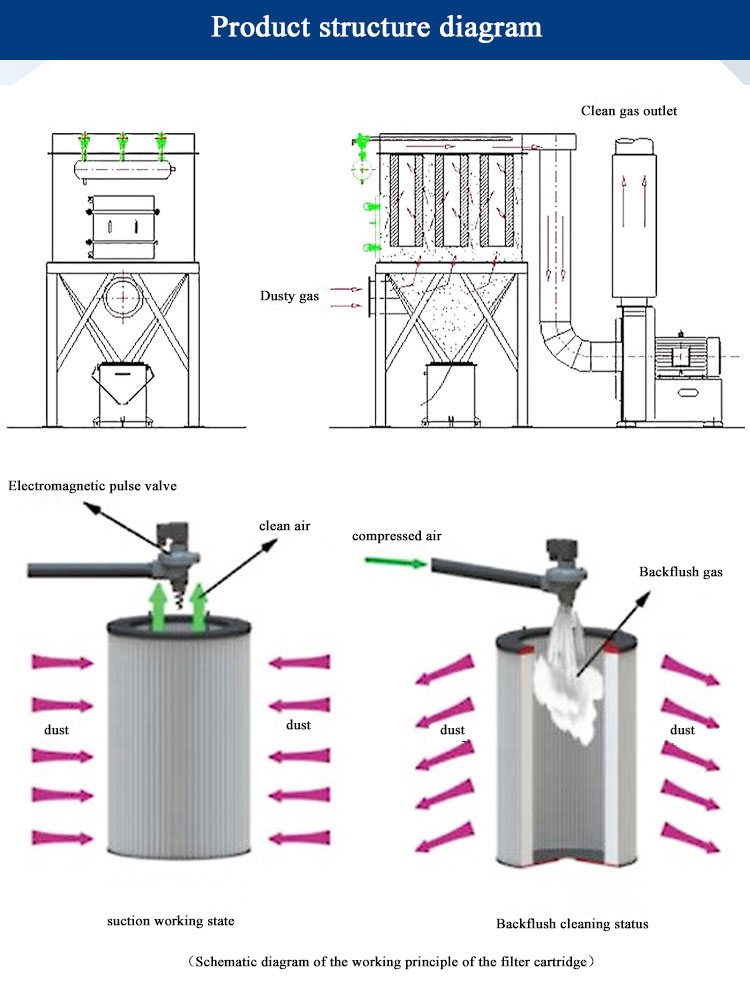

After the gas enters the dust hopper, some coarse particles in the air flow settle in the dust hopper under the action of dynamic and inertial forces due to the sudden expansion of air flow section and the action of air flow distribution plate. After the dust particles with fine particle size and small density enter the filter chamber, the dust is deposited on the surface of the filter material through the combined effect of Brown diffusion and screening, and the purified gas enters the clean gas chamber and is discharged by the exhaust pipe through the fan.

1. woodworking manufacturing: the grinding, polishing, saw, milling, planing process generated by the dust recovery treatment;

2. manufacturing: the dust generated by crushing, mixing, feeding, bagging operation process for recovery treatment;

3. hardware manufacturing: the grinding, polishing, saw, milling, planing process generated by the dust recovery treatment;

4. Food industry: recovery and treatment of flour, rice, milk powder, grain and oil, dust generated in the processing process;

5. chemical industry: chemical fertilizer, coating, washing powder, dust generated in the production process for recycling treatment;

6. Construction industry: Dust generated by the production process of cement, ceramics, glass, fiber, steel and stone.

Plastic profile mixing workshop filter drum dust collector

Similar ProductsVIEW MORE >