Flame cutting dust collector filter cylinder by a certain length of crisp filter material folded into a fold, the end of the star filter cylinder.

Flame cutting dust collector filter cylinder by a certain length of crisp filter material folded into a fold, the end of the star filter cylinder. Dust removal filter cylinder without cage bone, simple installation, more varieties of filter cylinder, there are fine and long and thick and short. Long and thin filter drum (such as φle; 160, L=1 ~ 2m), the gap between the pleats (such as 45 pleats) is large, the Angle is large, the pleats are few and shallow, the filter area is 2 ~ 5 times larger than the filter bag with the same diameter and length, the cleaning is easy and the effect is good; Suitable for concentration ge; 15g/m dust filtration dust removal, filtration wind speed 0.6 ~ 1.2m/min. Coarse and short filter cylinder (such as φ350, L=0.66m) large diameter, short length, pleats (120 ~ 350 pleats) and deep, pleats gap is small, filter area is large, compared with the same diameter with the same length filter bag area is 14 ~ 35 times larger, suitable for small field area, small space of the local layout; But because the fold Angle is small, dust is easy to accumulate, difficult to clean ash, suitable for concentration le; 5g/m dust filtering dust removal, filtering wind speed should not be gt; 0.6m/min.

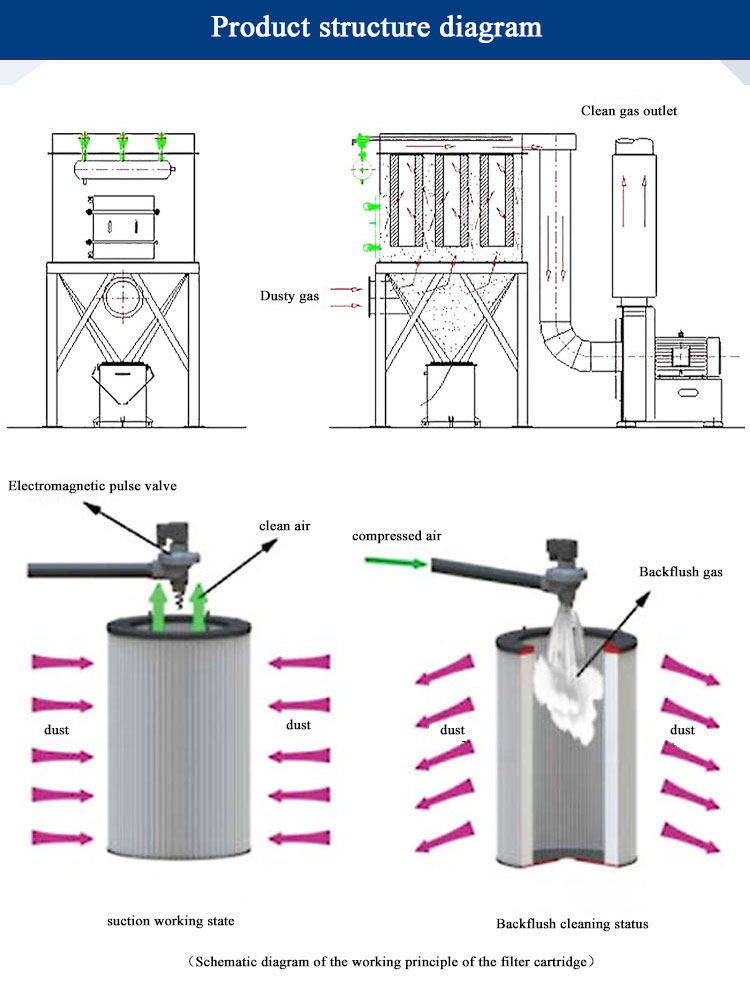

There are three ways to install the cylinder pulse precipitator: vertical, inclined and horizontal installation. The filter cylinder is installed vertically, and the dust is easy to settle to the ash hopper when the pulse is used. When inclined installation, the upper and lower filter cylinder overlap, compact structure, small area, easy to change the cylinder, but when cleaning, the dust of the upper filter cylinder settled on the lower filter cylinder, difficult to remove. Horizontal installation, the dust above the lower filter cylinder is more difficult to remove. Inclined cylinder dust collector is suitable for small and medium-sized dust removal system non-viscous, low concentration, coarse dust removal, but also suitable for the transformation of some old bag dust collector.

In modern industrial production, the cutting machine is applied more and more widely in the metal processing industry, which brings more and more serious pollution problems, and the dust control of cutting machine is more and more urgent. At present, there are two main ways to control the dust of cutting machine: wet treatment and dry treatment.

1. the selection of high quality and efficient flame retardant wood pulp fiber filter material from the United States, combined with advanced folding process, so that the filter cylinder has no combustion, filter area, small aperture, large air permeability, low resistance, high efficiency;

2. the end cover and the inner and outer protective net are made of high quality galvanized sheet, with good corrosion and rust prevention performance;

3. low hardness, high strength closed cell rubber seal, to ensure the air tightness of the filter cylinder;

4. the use of super adhesive, will not produce degel and cracking phenomenon, to ensure the service life of the filter cylinder and the use of high load safety (under normal operating conditions, the life of the filter cylinder can be up to 2 years).

5. greatly improve the effective filtration area;

6. ensure a low and stable pressure difference, improve the flow of air;

7, the filter cylinder element is small, easy to install;

8. It is especially suitable for industries with high dust concentration.

Flame cutting filter cartridge

Similar ProductsVIEW MORE >