Integrated cylinder dust collector is a new type of filter dust removal device

Integrated cylinder dust collector is a new type of filter dust removal device, with high purification efficiency, small size, large filtration area, good filtration effect, small pressure loss, long service life of the cylinder, quick and convenient installation and maintenance, continuous use, etc. The cylinder dust collector is mainly designed for controlling a large number of dust particles harmful to human body produced in the production of machinery processing, chemical production, powder recovery, construction manufacturing, medical production, food processing, furniture production and hardware processing. Different combinations meet different air volume requirements, and can meet the multi-process dust collection and treatment in the production workshop. The collection methods include mobile suction arm type and fixed suction hood to minimize dust escape into the workshop and ensure the working environment of the workshop.

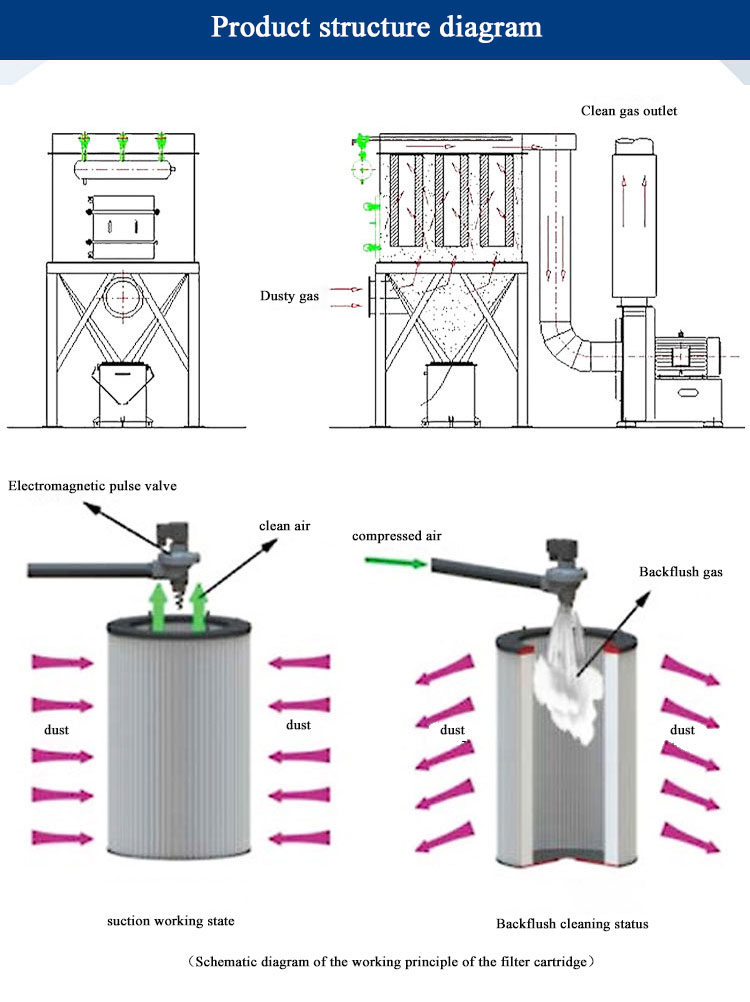

The cylinder dust collector operates under negative pressure, and the dust-bearing gas enters the box through the air inlet, due to the sudden expansion of air flow section and the action of air flow distribution plate. Some coarse particles in the air flow settle in the ash bucket under the action of inertia force: under the action of negative pressure in the folded filter material, the gas penetrates the filter material into the clean air chamber and is discharged from the outlet by the fan. The dust particles with fine particle size and small density enter the filter chamber and pass through

(1) High dust collection efficiency

The filter barrel filter adopts the filter element. When the filter begins, the filter equipment has a large filtration efficiency and becomes unstable. When the dust containing air enters the filter state, the dust on the surface of the filter material penetrates into the filter material to produce a filter layer.

(2) The pressure loss changes little

The pressure loss is related to the treatment air volume, dust concentration, dust properties and dust size. After the formation of a primary filter layer, the backwash mechanism of the dust collector can reverse wash the dust instantly during normal operation, and the pressure loss generated is small and stable.

(3) Large processing capacity

The air volume of pulsating reverse washing dust collector: it can reach the allowable range of 1~4 m^3/min according to the different types of filtered dust. The advantages of large relative processing air volume, reduced filtration area and small equipment setting area.

(4) The application of high dust concentration

Pulsating reverse washing type dust collector is suitable for dust treatment with dust concentration of 0.05~10kg/m^3. For places with high dust concentration, CYCLONE or settling tank can also be omitted. Pulsating reverse washing type dust collector can directly deal with it.

(5) Easy maintenance

The reverse washing device of pulsating reverse washing dust collector has fewer movable parts, so it has fewer faults, relatively less maintenance and easy maintenance.

(6) cylinder-type dust collector can be cleaned automatically

The filter material of the purifier is cleaned by a pulse injection mechanism controlled by a differential pressure sensor: when the purifier runs for a period of time, fine dust adsorbed on the surface of the filter material, making the filter material less permeable. The two detection heads of the differential pressure sensor are installed on the raw gas side and on the clean gas side. When the pressure difference detected by the differential pressure sensor exceeds a certain set value, the differential pressure signal will be output. After receiving the signal, the pulse generator will quickly start the pulse injection valve, and clean compressed air will be ejected from the valve port. The ejector air will purge the filter cylinder until the differential pressure is lower than another set value. The fine dust adsorbed on the surface of the filter material is removed under the action of air flow and falls in the dust collection bucket at the lower part of the chamber.

1, dust removal equipment compact structure, easy to maintain; Long service life of the filter drum, can be used for two years or longer; High dust removal efficiency.

2, suitable for a variety of working conditions, according to the characteristics of dust selection of different materials of the filter cylinder, to solve the problem of dust treatment;

3, building block structure, can be composed of the required processing air volume; Compared with conventional pulse dust collector, the injection pressure can be reduced by 20% ~ 40%.

All-in-one cartridge dust collector

Similar ProductsVIEW MORE >