Drum dust collector has the advantages of small volume, good efficiency, low investment, easy maintenance, but because of its small equipment capacity, it is difficult to combine into large air volume equipment, low filtering wind speed, narrow application range, only in food, welding and other industries, so it can be widely promoted in the future over the years.

Drum dust collector has the advantages of small volume, good efficiency, low investment, easy maintenance, but because of its small equipment capacity, it is difficult to combine into large air volume equipment, low filtering wind speed, narrow application range, only in food, welding and other industries, so it can be widely promoted in the future over the years. In recent years, with the continuous development of new technology and new materials, the structure and filter material of the dust collector have been improved, making the filter barrel dust collector widely used in cement, steel, electric power, food, metallurgy, chemical and other industrial fields, the overall capacity increased several times, becoming a filter area > 2000 square meters large dust collector.

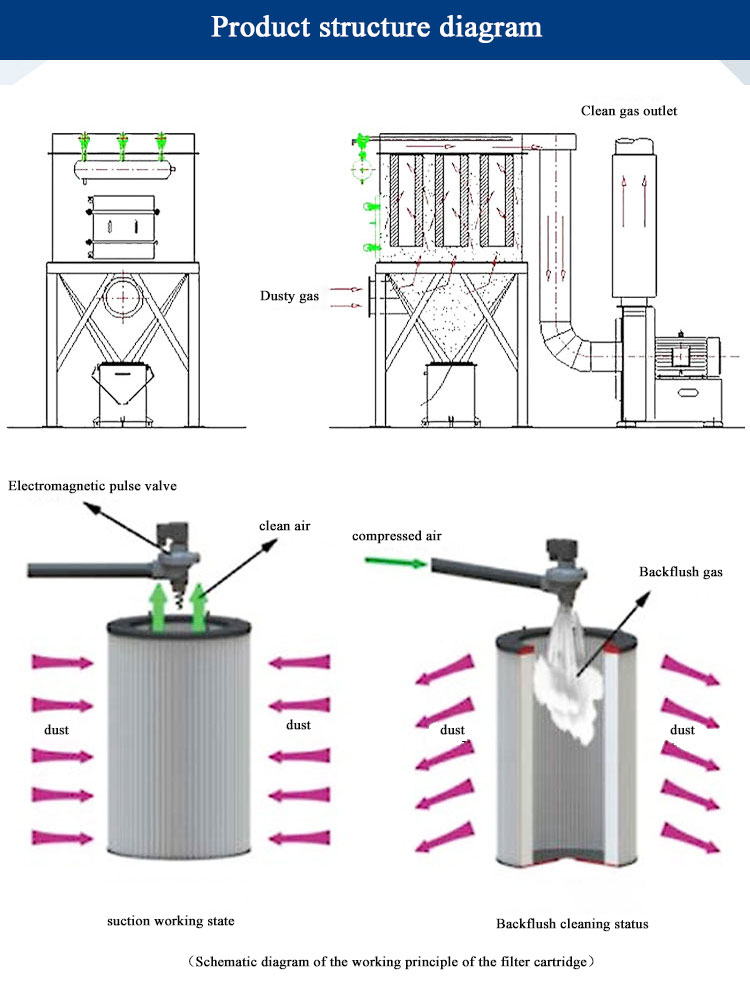

Filter drum dust collector refers to a filter composed of a filter cylinder as a filter element, its structure is composed of inlet and outlet tuyere, feeding box, ash hopper, ash cleaning device, air distribution plate, filter drum and electric control device (pulse control device), additional equipment is unloading valve, soft connection and mobile ash trolley.

Drum dust collector has the advantages of small volume, good efficiency, low investment, easy maintenance, but because of its small equipment capacity, it is difficult to combine into large air volume equipment, low filtering wind speed, narrow application range, only in food, welding and other industries, so it can be widely promoted in the future over the years. In recent years, with new technology, new materials No

After the dust-bearing gas enters the dust collector, some coarse particles in the air flow sink directly under the action of gravity and inertia force, and dust particles with fine strength and low density are deposited on the surface of the filter material after entering the dust chamber through the combined effect of Brown diffusion and screening. The purified gas enters the clean gas chamber and is discharged from the outlet through the fan. In order to clean the filter cylinder, the compressed air is used to generate strong air flow, which is released to the center of the filter cylinder through the electromagnetic valve. Like vibration waves, the dust gathered on the surface of the filter cylinder will shake and blow down and fall into the ash bucket below. In order to ensure the normal and continuous operation of the cylinder dust collector, the pulse control system is programmed for backblowing.

Pulse cartridge dust collector

Similar ProductsVIEW MORE >