The vertical filter cartridge dust collector is a new type of filter and dust removal device.

The vertical filter cartridge dust collector is a new type of filter and dust removal device. It has the characteristics of high purification efficiency, small size, large filtering area, good filtering effect, small pressure loss, long service life of the filter cartridge, fast and convenient installation and maintenance, and continuous use. The filter cartridge dust collector is mainly designed for the treatment of a large number of dust particles that are harmful to the human body during production in mechanical processing, chemical production, powder recovery, construction manufacturing, pharmaceutical production, food processing, furniture production and hardware processing. The combination meets the needs of different air volumes, and can meet the multi-process dust collection and treatment in the production workshop. The collection methods include mobile suction arm type and fixed suction hood to reduce dust escaping into the workshop and ensure the working environment of the workshop.

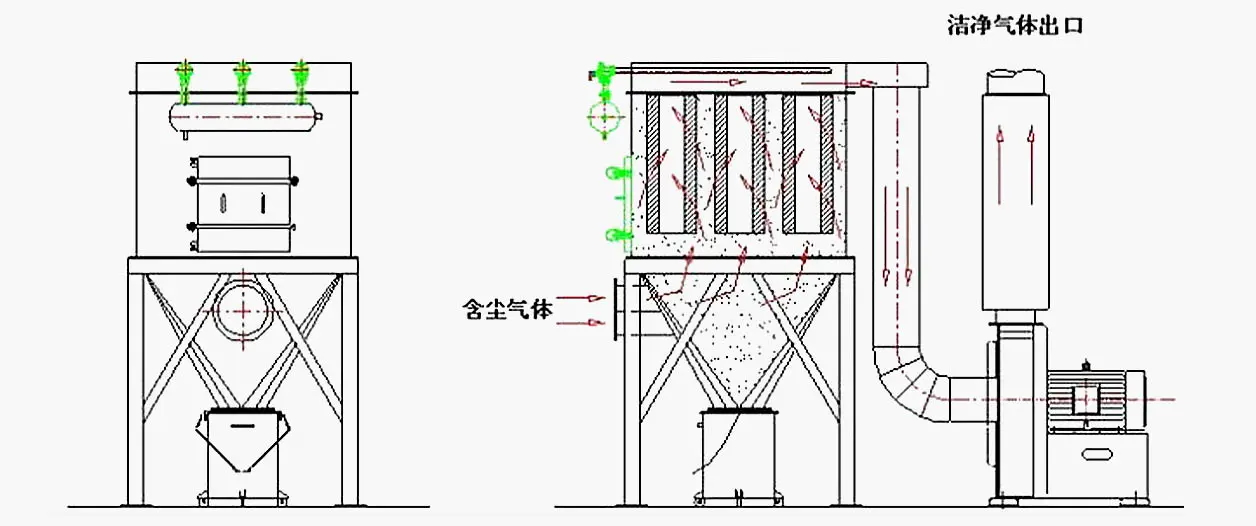

After the gas enters the dust hopper of the vertical filter cartridge dust collector, due to the sudden expansion of the airflow section and the action of the airflow distribution plate, part of the coarse particles in the airflow settle in the ash hopper under the action of dynamic and inertial forces; dust with fine particle size and small density After the particles enter the dust filter chamber, the dust is deposited on the surface of the filter material through the combined effects of Brownian diffusion and sieving, and the purified gas enters the clean air chamber and is discharged by the exhaust pipe through the fan.

(1) High dust collection efficiency

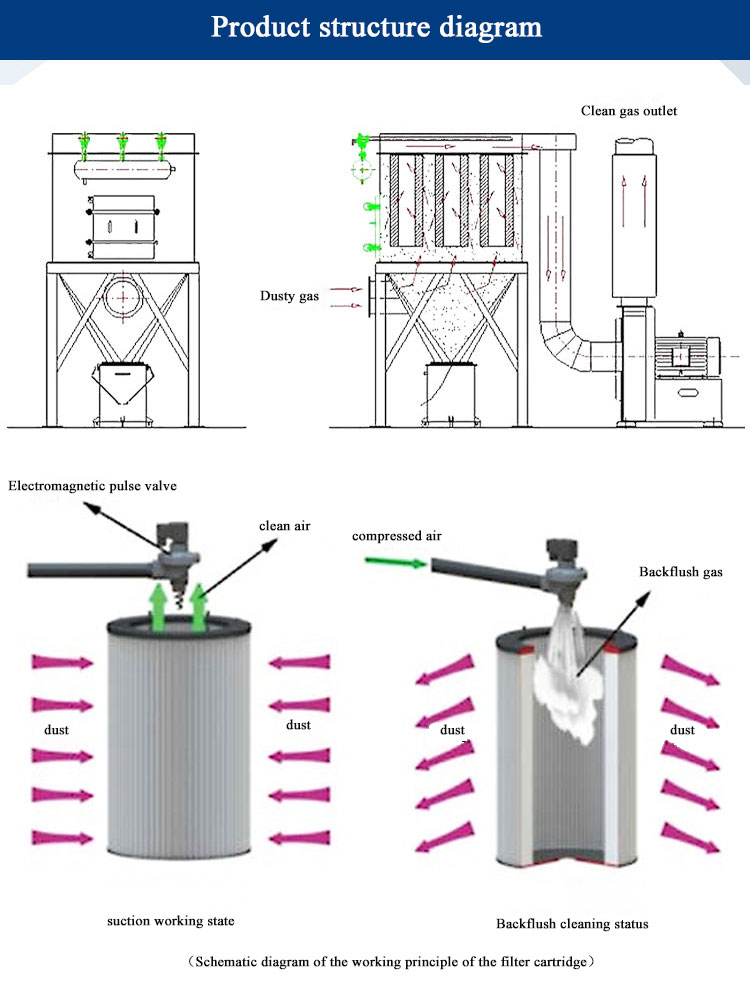

The filter cartridge dust collector adopts a filter element. At the beginning of the filtration, the filter equipment has a large filtration efficiency and becomes an unstable state. When the filtration state begins to contain dusty air, the dust on the surface of the filter material penetrates into the filter material to generate a filter layer. After the filter layer is generated, the filter material is in a stable state, and the filter material during filtration, backwashing, and backwashing achieves high dust collection efficiency.

(2) Small change in pressure loss

The pressure loss is related to the processing air volume, dust concentration, dust properties, and dust particle size. After the primary filter layer is formed, the backwash mechanism of the dust collector can instantly backwash and shake off the dust during normal operation, and the resulting pressure loss is small and maintain stability.

(3) Large processing capacity

The air volume of the pulsating backwash dust collector can reach the allowable range of 1~4 m^3/min depending on the type of filtered dust. It has the advantages of large processing air volume, reduced filtering area and small equipment setting area.

(4) Applicable to occasions with high dust concentration

The pulsating backwash type dust collector is suitable for dust treatment with a dust concentration of 0.05~10kg/m^3. When used in places with high dust concentration, the cyclone dust collector (CYCLONE) or sedimentation tank can also be omitted. Washable dust collectors can be processed directly.

(5) Easy maintenance

The backwashing device of the pulsating backwashing type dust collector has few movable parts, so there are few faults, and the maintenance is relatively reduced and easy.

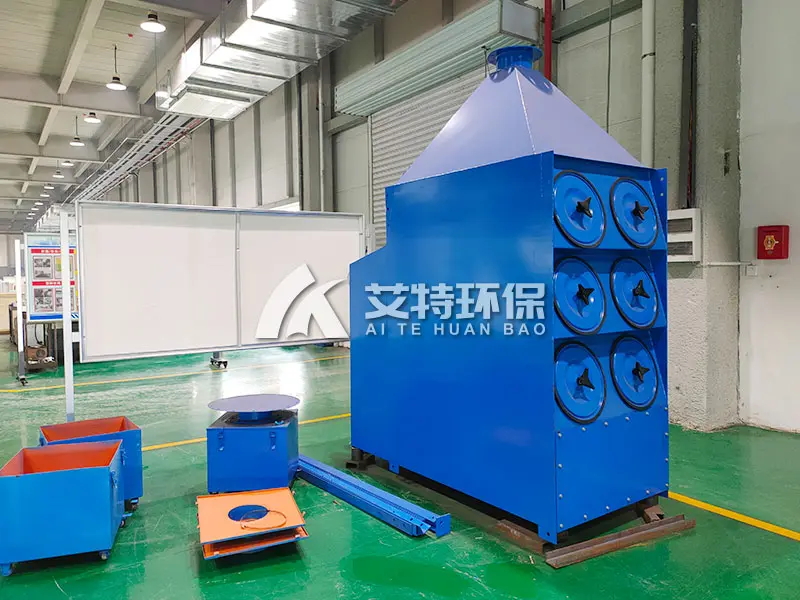

Vertical filter cartridge dust collector

Similar ProductsVIEW MORE >