Explosion-proof cartridge filter is composed of a filter simple as a filter element or a pulse jet filter.

Explosion-proof cartridge filter is composed of a filter simple as a filter element or a pulse jet filter. According to the installation method, the filter can be divided into inclined insert type, side loading type, lifting type and jacket type. According to the filter barrel material, it can be divided into long fiber polyester filter barrel filter, composite fiber filter simple filter, anti-static filter barrel filter, flame retardant filter barrel filter, coated filter barrel filter, nano filter barrel filter, etc.

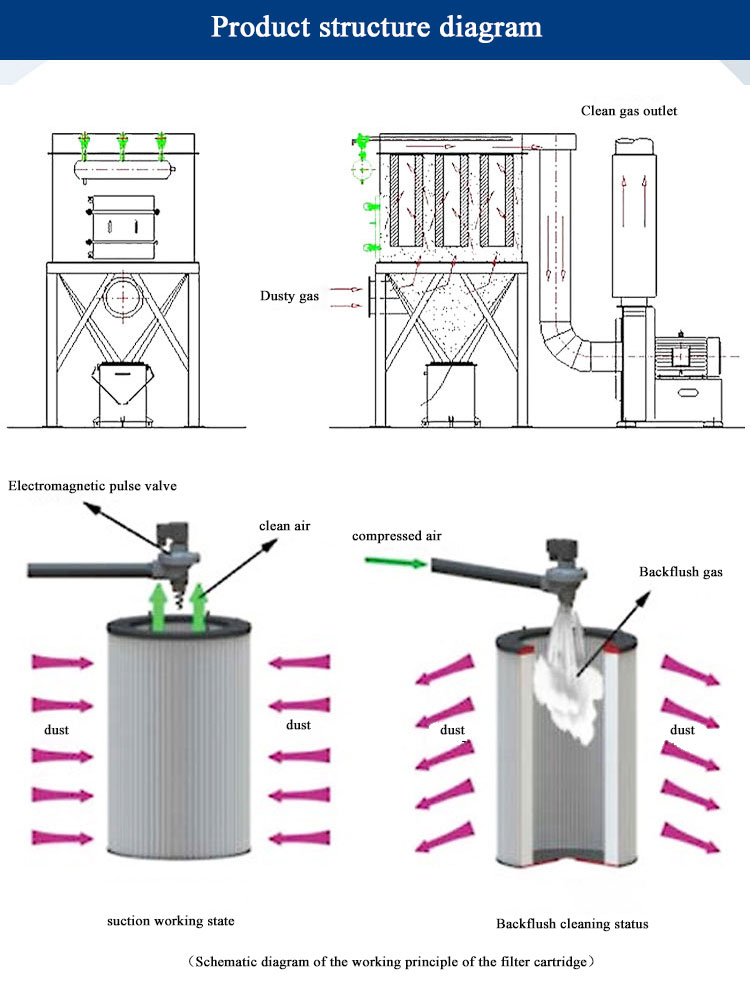

After the dust-bearing gas enters the dust hopper, due to the sudden expansion of air flow section and the action of air flow distribution plate, some coarse particles in the air flow settle in the dust hopper under the action of dynamic and inertial forces. After the dust particles with fine particle size and small density enter the filter chamber, the dust is deposited on the surface of the filter material through the combined effect of Brown diffusion and screening.

The purified gas enters the clean gas chamber and is discharged by the exhaust pipe through the fan. In order to clean the filter cylinder, the compressed air (0.4-0.7Mpa) is used to produce strong air flow and released to the center of the filter simple through the electromagnetic valve. Like vibration waves, the dust gathered on the outer surface of the filter Jane oscillates and blows down and falls into the ash hopper below.

In order to ensure the normal and continuous operation of the filter Jane dust removal, the pulse control system carries out reverse blowing according to the set program.

1. The filter material is folded into a cylinder, so that the density of the filter material layout is large, so the dust collector is compact in structure and small in volume.

2. Compared with the cloth bag and the filter cylinder occupying the same space, the filtration area of one filter cylinder is greater than the sum of the filtration area of 10 cloth bags.

3. The height of the filter cylinder is small, easy to install, and the maintenance workload is small.

4. Modular design, block type assembly, easy and quick installation, to meet all kinds of limited space on site.

5. Adopt heavy carbon steel structure and heat curing powder spraying equipment surface, with good strength and durability.

6. Meet the requirements of relevant standards for factory air quality.

7. There is a standard independent module which can accommodate 2000-10000m3/h air flow.

8. Dust is automatically cleaned and recovered by pulse injection of compressed air into the filter cylinder.

9. Venturi tubing is used in the nozzle to draw in more air with less energy and improve the cleaning effect of the reverse pulse, thus reducing the pressure drop.

Explosion-proof cartridge filter

Similar ProductsVIEW MORE >