Concrete mixing plant dust removal filter cylinder according to the cement, fly ash, stone powder, mineral powder, chemical powder and other powder through the aperture, the design of dust collector filter element through the diameter and adhesion effect to filter element aperture, can fully meet the filtration requirements of each powder substance.

Concrete mixing plant dust removal filter cylinder according to the cement, fly ash, stone powder, mineral powder, chemical powder and other powder through the aperture, the design of dust collector filter element through the diameter and adhesion effect to filter element aperture, can fully meet the filtration requirements of each powder substance.

It can not only meet the requirements of air delivery in bulk car and air delivery after dismantling of finished goods, but also ensure that there is no negative pressure in the warehouse when powder materials are used.

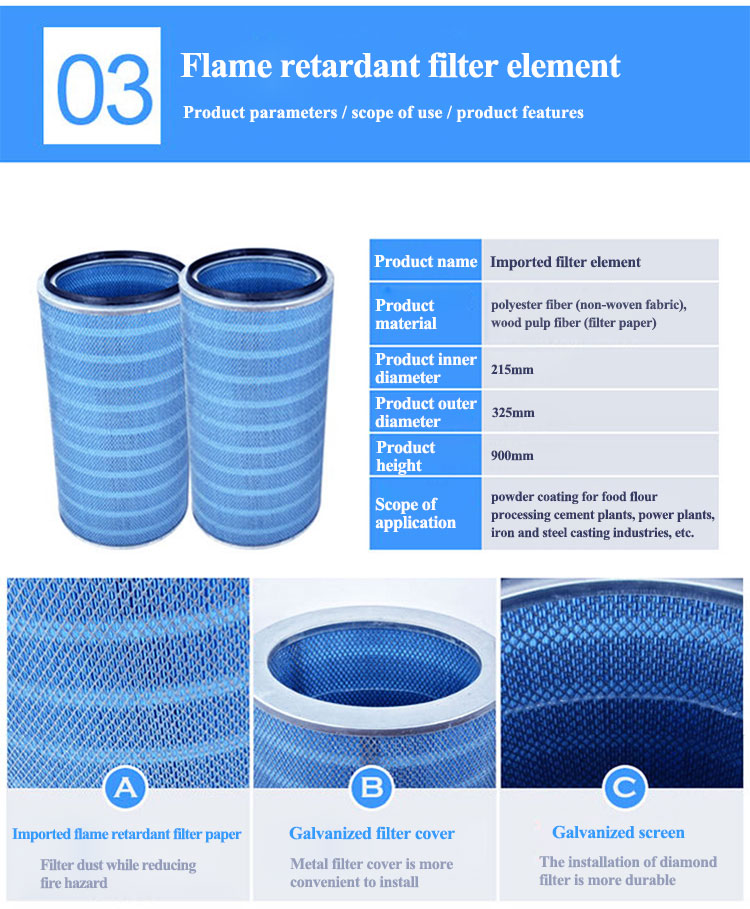

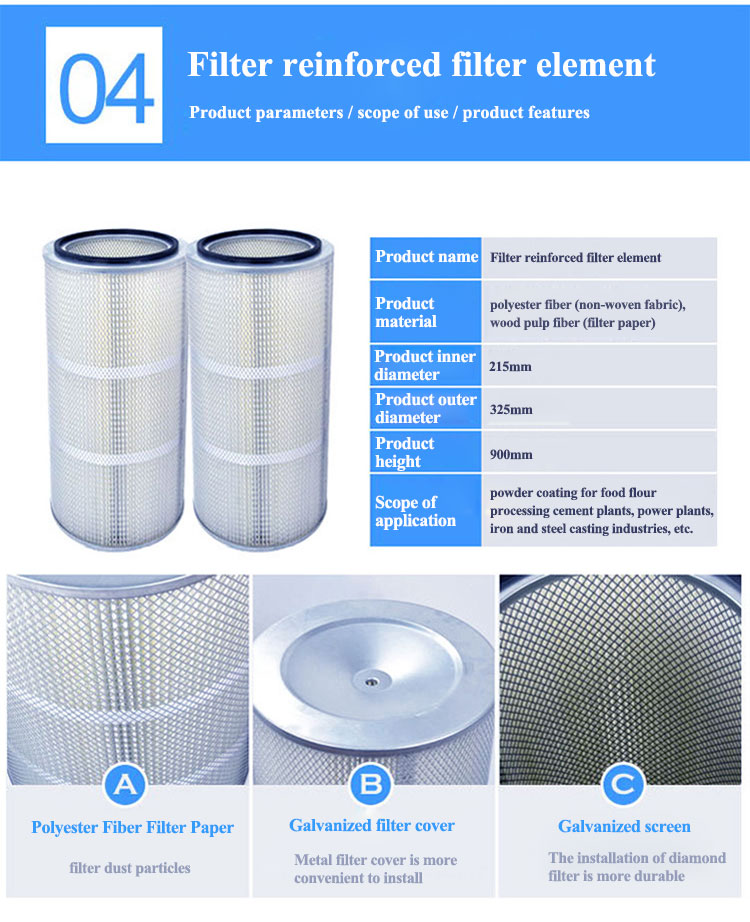

It has the advantages of small volume and compact structure. 14 filter elements imported from Germany. Standard spare parts, easy operation and maintenance, greatly reduce the dust spill caused by the pollution of the environment, to meet the national environmental protection requirements, is the essential equipment of high quality mixing plant.

Filter area: 24m³

Exhaust air volume: > 1500m³/h

Filtration efficiency: > 99.9%

Structure form: cylindrical

1, Chemical production line, pharmaceutical production line, cigarette production line, glass production line, powder coating line, cement production line;

2. Drilling machine dust collecting box, painting line, electrostatic spraying system;

3. Shipbuilding, electric power, metallurgy, engineering machinery;

4. Other various industrial dust removal and dust recovery system.

Concrete mixing plant dust removal filter cylinder

Similar ProductsVIEW MORE >