Comparison and analysis of the performance of filter cartridge dust collector and cloth bag dust collector

Cylinder dust collector is a device that can separate dust from the discharged dust-containing gas. It has the function of reducing the dust concentration in the discharged gas. It is an important equipment in the dust removal system. In more types of filter drum dust collector, widely used, rapid development is the filter drum dust collector and bag dust collector, both are widely used in various industrial fields, belong to the dry filter mode, this paper will talk about the difference between the filter drum dust collector and bag dust collector.

First, the filter material of the filter cylinder dust collector and the bag dust collector is different

Bag dust collector mainly originated in the 1880s, is a kind of dry filter dusty gas device, used in the occasions containing dry, fine, non-fiber dust. Its filtration materials are often polyester, PE, NOM, polypropylene, aramid, PP, PPS, P84, PTFE, and can be continuously operated at 190 degrees. Therefore, bag dust collector is commonly used in industrial kiln, coal-fired boiler and waste incineration.

Filter dust collector common polyester fiber, nanofiber, wood pulp paper, PTFE surface, flame retardant and other processing process, the filter material folded into a fold, a single filter area, high dust removal efficiency, low resistance, good performance.

Two, the filter accuracy of the cartridge dust collector and the bag dust collector is different

The cloth bag is sewn into a filter bag by soft filter material, which is inserted into the skeleton made of steel bar welding. The filter bag is dense and firm. The filter material is long polyester fiber and the post-treatment material is mostly single ordinary industrial polyester cloth. The filtration accuracy of bag dust collector is mainly determined by the matching filter bag. The filtration accuracy of needle felt single-layer filter bag is generally 5~10μm, and the accuracy can reach 1μm after composite treatment.

Filter filter material is folded arrangement to form a cylinder, no skeleton, brief, large spacing between the cylinder, no secondary pollution. The filtration accuracy of conventional polyester fiber filter material is 1~5μm, after PTFE coating treatment can reach 0.3μm, some special processing technology can make its filtration accuracy reach 0.1μm, can meet the H13 filtration standard.

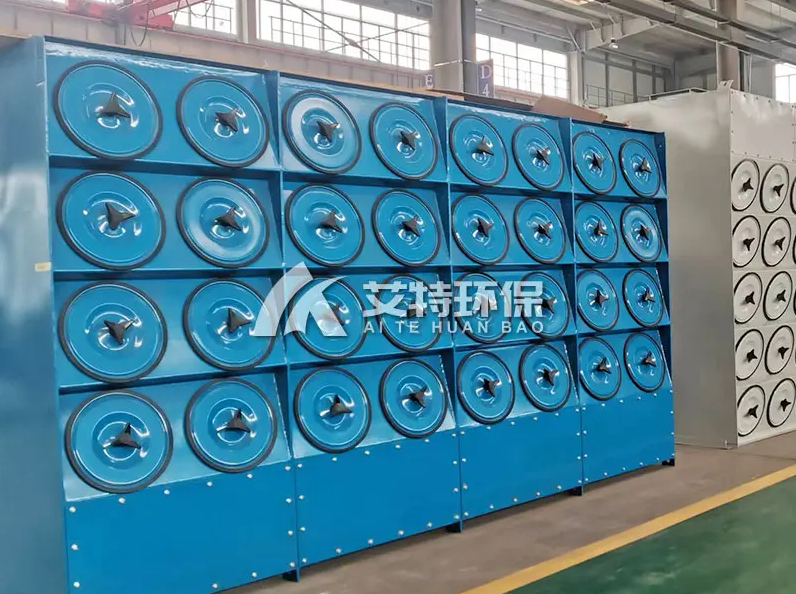

Three, the volume and size of the cylinder dust collector and the bag dust collector are different

The volume of the dust collector is mainly determined by the structure, size and quantity of the filter, which are determined by the filter area, and the filter area is determined by the processing air volume and filter wind speed. Under the condition of the same filter area, the filter barrel dust collector is at least 1/3 smaller than the bag dust collector, because the difference between the filter area of a single size bag and the filter cylinder is relatively large.

Four, the use and maintenance costs of cartridge dust collector and bag dust collector are different

In terms of equipment cost, the cost of the ordinary cartridge filter is about 30%~50% higher than that of the ordinary bag filter, which is mainly due to three reasons: first, the cost of the cartridge filter is much higher than that of the bag filter; Two, generally, each filter cylinder will be equipped with a solenoid valve, bag dust collector is usually a row or a row with a solenoid valve, the solenoid valve and the control cost of the filter cylinder dust collector will be relatively high; Three, the general filter cylinder dust collector is used in high-precision filtering occasions, because of its small volume, it is generally made of cold-rolled steel plate laser cutting, welding, fine grinding, pickling phosphating, electrostatic spraying, high temperature baking and other processes, and the product is beautiful.

In terms of equipment maintenance, it is easier to maintain the cartridge dust collector, and the replacement of the solenoid valve and the cartridge is more convenient. However, most of the installation of the cloth bag dust collector is inserted from top to bottom, and its maintenance and replacement need to climb to the top of the dust collector and remove the top plate and the electromagnetic pulse component and skeleton, which is not convenient to use.

Previous article: What is the filtration accuracy and cleanliness of high precision oil filter?

Next article:HYLQ series sintered felt dust filter