What if there is water in the oil? Use a coalescing dehydrating oil filter

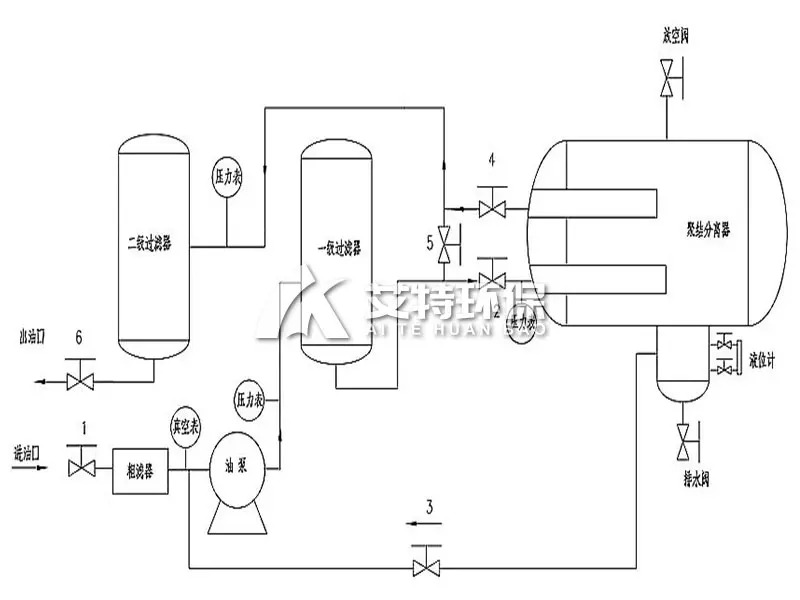

Coalescing dehydrating oil filter is designed to solve the problem of excessive water content in various oils. HO series coalescing dehydrating oil filter is developed by using the technology of coalescing separation.

When the oil flows through the coalescence separator, it goes through four stages of filtration, coalescence, sedimentation and separation inside to achieve the function of filtering particle pollutants and removing water.

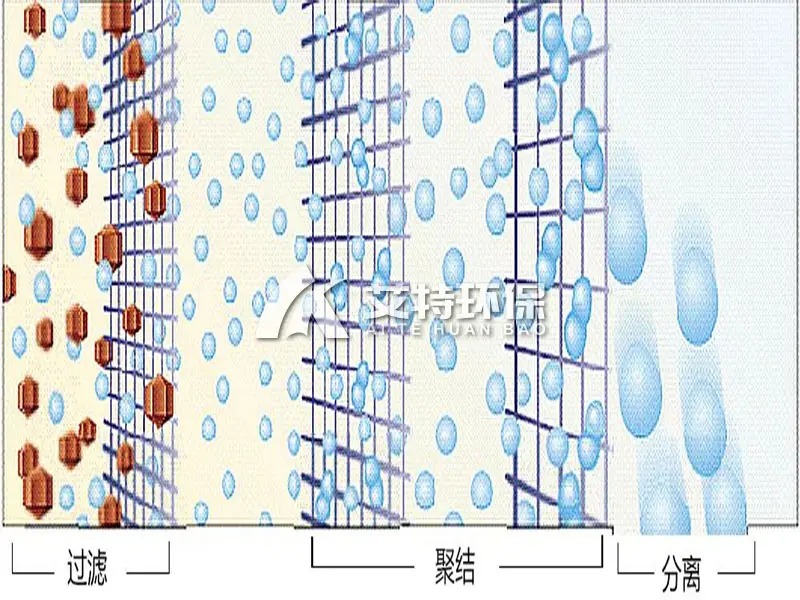

The oil first flows from inside to outside through the coalescating filter element. The coalescating filter element has good hydrophilicity and is composed of special glass fiber and other synthetic materials. It is specially prepared for the dehydration of the oil and has the dual function of filtering particle pollutants and coalescating water.

The outside demulsification coalescence layer will converge the tiny water droplets in the oil into water droplets. The larger water droplets settle to the sedimentation tank by their own gravity, and the smaller water droplets will be carried by the oil to the separation filter element without settling.

The separation filter element is made of specially treated stainless steel mesh, which has good hydrophobicity. When the oil flows through the separation filter element from the outside to the inside, the small water droplets are effectively intercepted outside the filter element, only letting the oil through, not letting the water through, so as to further separate the water.

Coalescing dehydrating oil filter can adapt to different media by replacing different materials of filter element:

1. Gasoline, kerosene, diesel and other fuel oil;

2. Oil and other low viscosity hydraulic oil, lubricating oil;

3. Medium viscosity hydraulic oil, lubricating oil;

4. Filter medium viscosity is larger, can increase the heater.

Field application case