What is a self-cleaning air filter

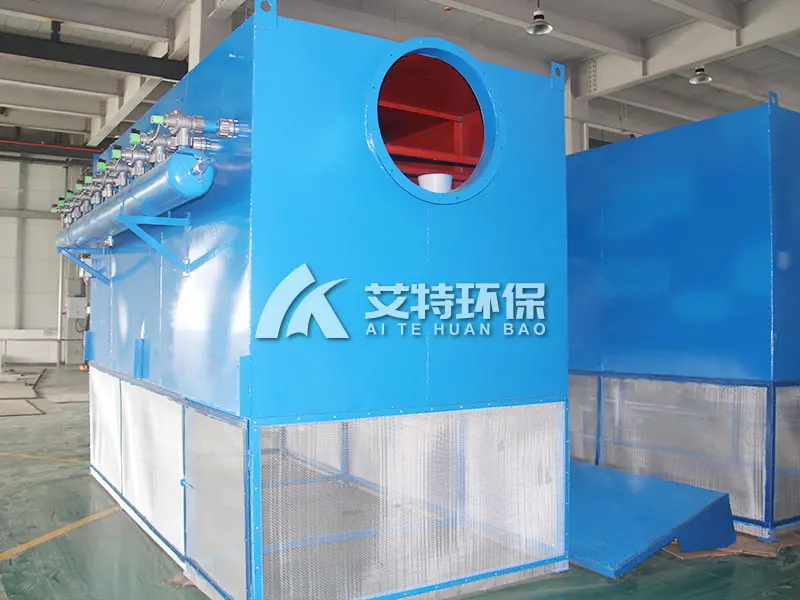

Air inlet filter, also known as self-cleaning air filter, its core filter element adopts cylinder filter, so it is also a kind of cylinder dust collector. Self-cleaning air filter adopts laser cutting, CNC machine tool processing, mold welding, modular manufacturing, electrostatic spraying, building block assembly, seenwork to create, especially for ultrafine dust has a very high trapping ability.

Dust collector is also called dust collector. It mainly collects valuable dust after grinding and crushing. It is also called powder collector in the industry. For example, lithium cathode materials, graphene materials, pharmaceutical grinding, food flour and other dust collection after grinding is usually called powder collector. Because the filter cylinder filter material is a fold type structure, and the bag filter material is a smooth structure, so under the same space conditions, the fold structure is larger than the smooth structure of the filter area, the development area of a filter cylinder is equal to the sum of the development area of multiple bags.

Therefore, in terms of the same air volume and the same filtration area, the installation size of the filter barrel dust collector is smaller than the area of the bag dust collector, so this is one of the reasons why the current environmental dust removal equipment is rebuilt and the bag dust collector is replaced with the filter barrel dust collector.

The dust collector adopts the filter cylinder as the core filter unit and the compressed air is sprayed to clean the dust. Filter filter according to different materials, usually can be divided into long fiber polyester filter filter, composite fiber filter filter, anti-static filter filter, flame retardant filter filter, PTFE coated filter filter, explosion-proof filter filter, nano-filter filter, etc.

Matching filter element

Product characteristics

1, this product can be according to user requirements at the bottom of the dust collection box, dust screen, water rinse dust removal method to solve secondary pollution;

2. The device is controlled by the intelligent distributor, and there are three self-cleaning methods, namely (1) timing; (2) pressure difference; (3) Manual;

3, the equipment can realize the automatic cleaning of the air filter element, so that the equipment runs as usual, without affecting the normal work of other filter elements;

4, can work normally under relative humidity conditions;

5, the filter area is large, the flow rate is low, the resistance loss is small, and the liquid crystal display resistance loss;

6, filter element long service life, under general environmental conditions, filter element replacement cycle can be up to 2 years;

7, high degree of automation, the main components of imported parts, can realize unmanned operation;

8, back blowing less air consumption, generally 0.1 ~ 0.3m³/min(inhalation state); The pressure is 0.4 ~ 0.6Mpa;

9, the weight of the equipment is light, cloth bag type with the capacity of 1/3-1/2;

10, reasonable design, no bending pipe design, high-rise building block type combined, easy to install, fast;

11. For products with special requirements, Jiajiebao can carry out non-standard design according to customer requirements to meet user needs.