If there is gas leakage, the gas drain can be dealt with immediately to avoid gas leakage. What are the precautions for using anti-leakage gas drains in the metallurgical industry?

First,When the gas drain is used in a high temperature environment, the gas drain has fully enclosed heat insulation measures, so that the gas drain will not cause freezing.

Second,The gas drain has a gas evacuation device, which can empty the air when adding water to the gas drain to avoid the phenomenon of air resistance outside the drain. The leak-proof gas drain has a drain outlet. If the gas drain works under the condition of clean gas, the gas drain can be drained according to the usage to ensure the normal operation of the gas drain.

Third,Installation and use

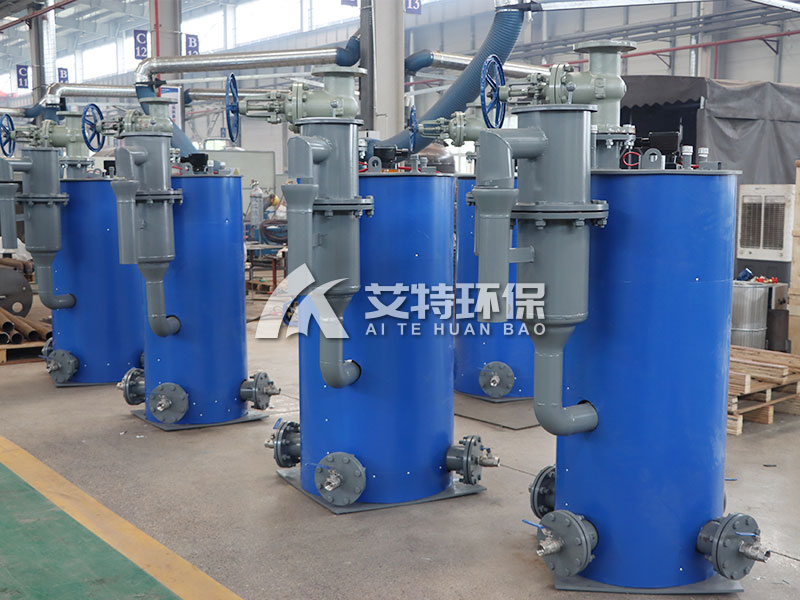

1. The gas drain should be installed on a flat ground foundation. The gas drain base can be welded with the embedded parts of the equipment foundation. The equipment foundation should be stable to avoid collapse or bending.

2. The gas drain should be installed vertically without bending to ensure the normal operation of the gas drain.

3. The on-site gas pipeline and the gas transfer pipe of the gas drainer are connected to each other, and gaskets should be used at the connection between the flanges to ensure that the container is strict and the gas does not leak to the outside.

4. The condensed water drain pipe of the gas drain should be heated to the adjacent sewer, and the condensed water should not be directly exhausted under the equipment foundation.

5. Gas discharge and warning signs around the fence to avoid collision leaks and other accidents.

6. After the gas drain is used, add water to the gas drain. When adding water, first open the exhaust pipe cap or exhaust valve of the gas drain, and then add water to the gas drain through the water inlet above the gas drain. If the condensate drain pipe inside the gas drain is dripping water, the gas drain is filled with water. After adding water, seal the lid of the gas drain or remove the vent valve to avoid gas leakage!

7. When choosing an electric heat tracing gas drain, it is necessary to connect the electric heat tracing junction box and the on-site working power supply to each other. Pay attention to the connection between the terminals of the connecting line and the connection.

8. The user can discharge and clean the gas discharge device according to the dust content of the gas and the on-site use of the equipment. When the gas discharge device is supplying water, remove the gas valve, cut off the power supply, prevent open flames, and start work in good light. After the water supply is completed, add water to the gas drain again!

Previous article: Detailed introduction of gas drain

Next article:Fault judgment and elimination of brush type self-cleaning filter