Air separation equipment is a device that uses air as raw material, converts air into liquid through compression and deep freezing, and then gradually separates inert gases such as oxygen, nitrogen, and argon from liquid air through rectification. Widely used in traditional metallurgy, new coal chemical industry, large-scale nitrogen fertilizer gas supply and other fields.

For air separation equipment, dust is one of the main reasons that affect the long-term normal operation of the equipment. The fouling of dust inside the equipment will affect the airflow movement, destroy the balance of the impeller, cause the shaft vibration of the rotor to aggravate and exceed the standard, and make the surge curve drift.

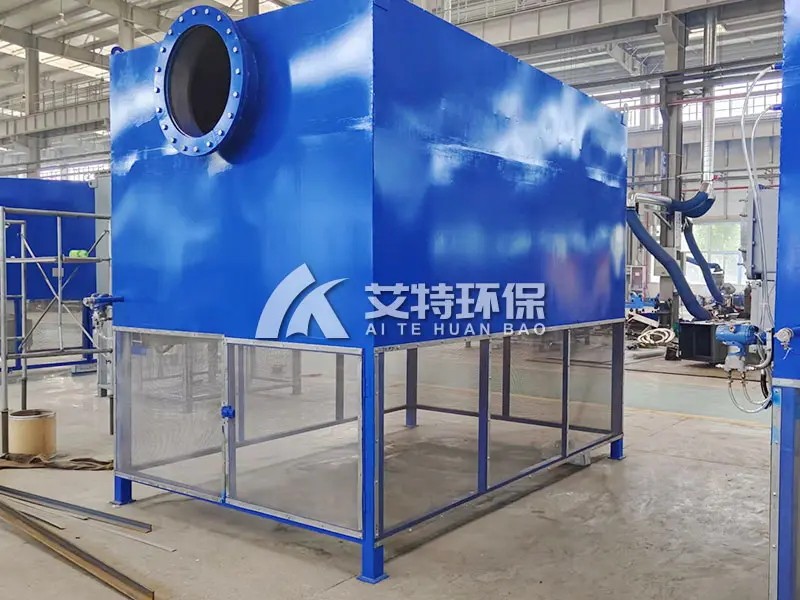

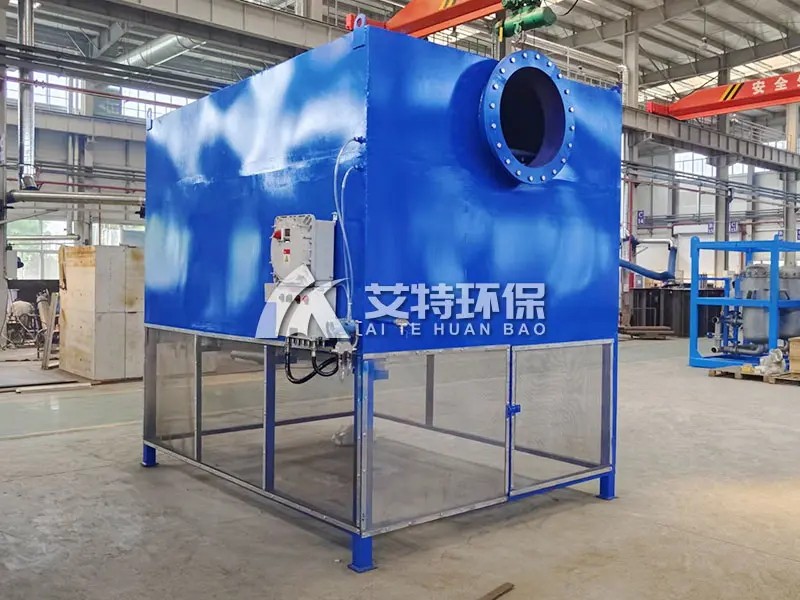

Compared with the traditional air filtration technology equipment, the self-cleaning air filter system has the characteristics of simple structure design, long service life of filter elements, and small workload of maintenance personnel. The filtration working principle of the self-cleaning air filter is that the air passes through the filter cartridge of the self-cleaning air filter. Under the action of gravity, inertia, diffusion, static electricity and other comprehensive factors, the dust particles in the air settle on the filter element. The filtered and purified air needs to be conveyed out through the venturi to the outlet header.

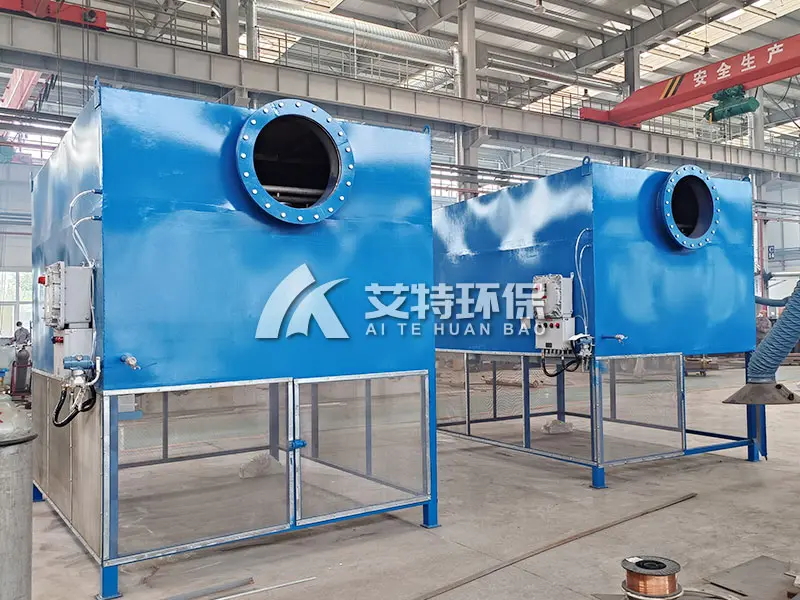

The self-cleaning air filter is composed of four parts: the filter cartridge, the self-cleaning system, the pulse backflushing cleaning device and the control system. Etc.

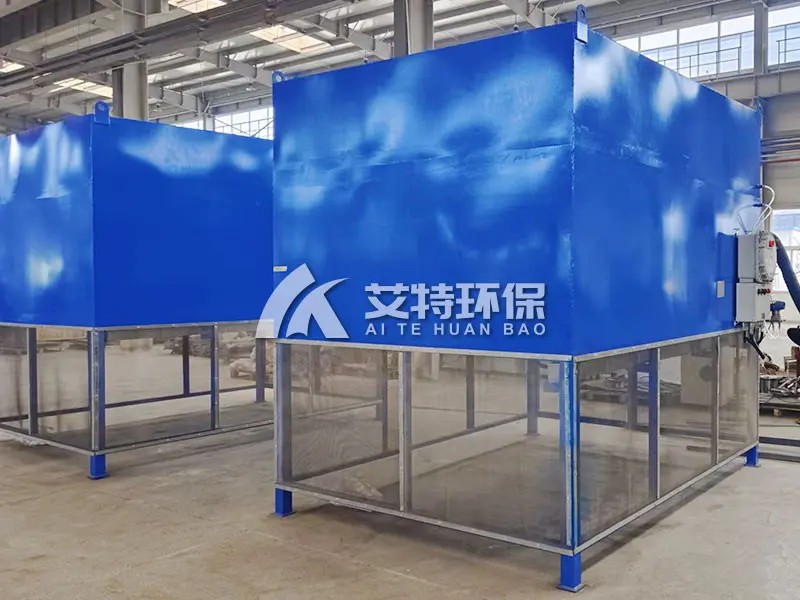

A single compressor needs to be equipped with a separate filter, which is arranged at the upper air outlet at the same time. At present, self-cleaning air filters are widely used in air separation devices, and have a high ability to capture fine dust; at the same time, they can realize automatic cleaning of air filter elements, so that the equipment can operate as usual without affecting the normal operation of other filter elements.