At present, the country is vigorously promoting the implementation and implementation of policies related to atmospheric governance, which has brought new growth momentum to the air filtration equipment industry. From the overall trend, although the current stage of the epidemic has slowed down the growth rate of domestic economic development, due to timely regulation, the impact on the air filtration equipment industry is limited. In some steel mills and chemical plants, large and medium-sized gas turbines, blowers and other equipment are used, and the dust concentration will be relatively high, and the air purification index is generally difficult to achieve, so it is necessary to use air filters. The air filter is a new type of air filter, which can carry out long-term and continuous air purification for air-consuming equipment.

First,Product introduction

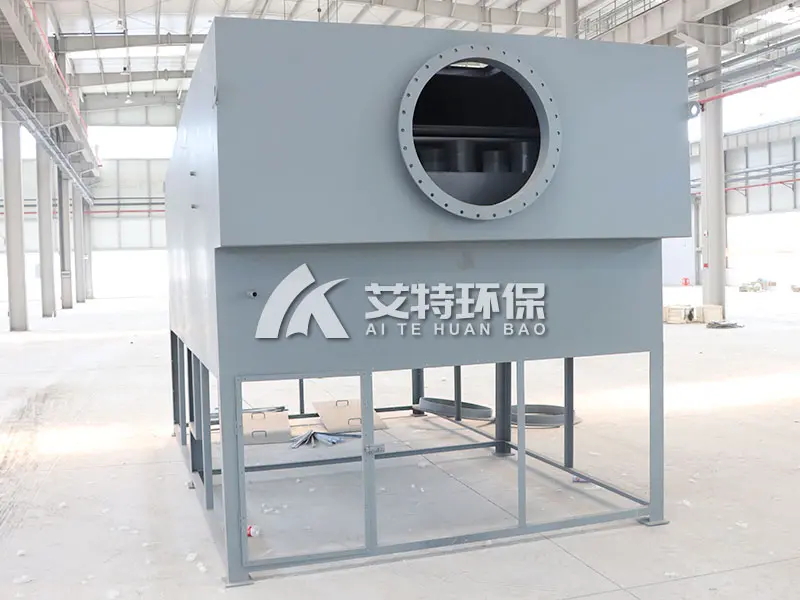

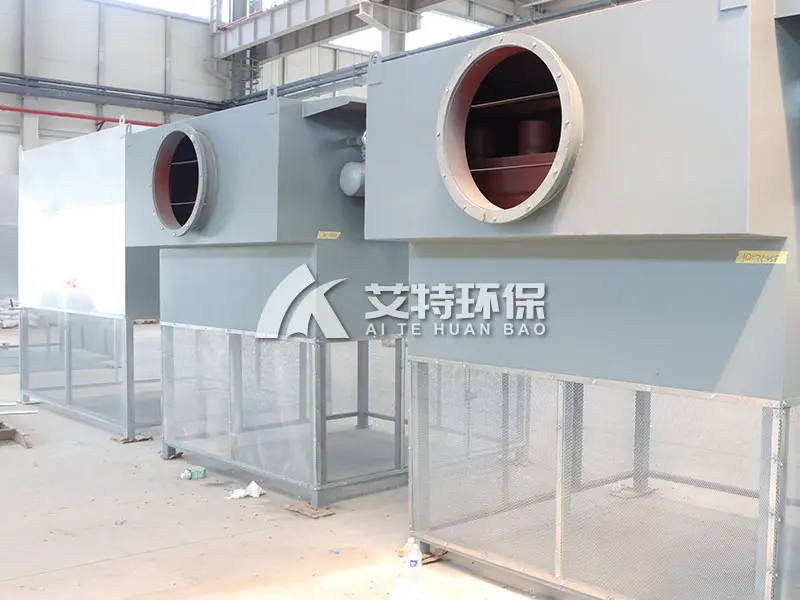

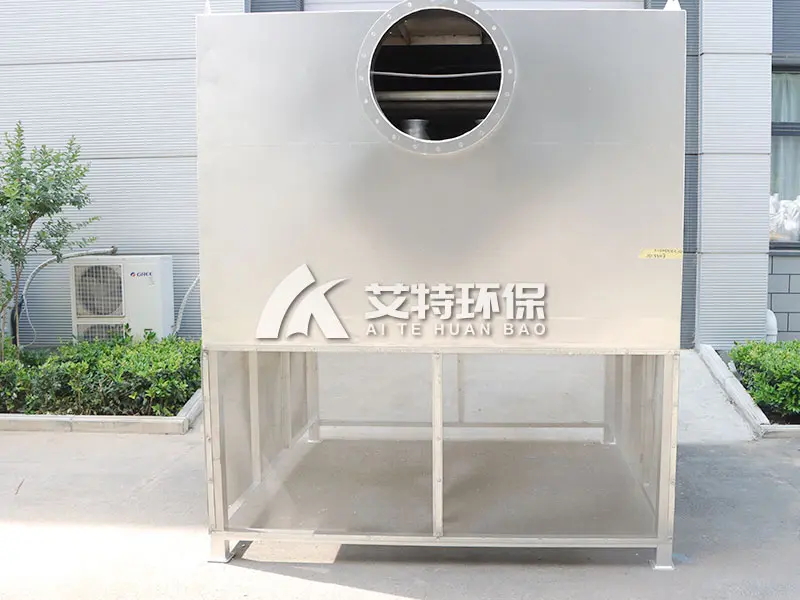

Self-cleaning air filter is a kind of filter with automatic cleaning function for air filtration. It can well filter out the fine pollutants emitted from the production process.

Second,Working principle

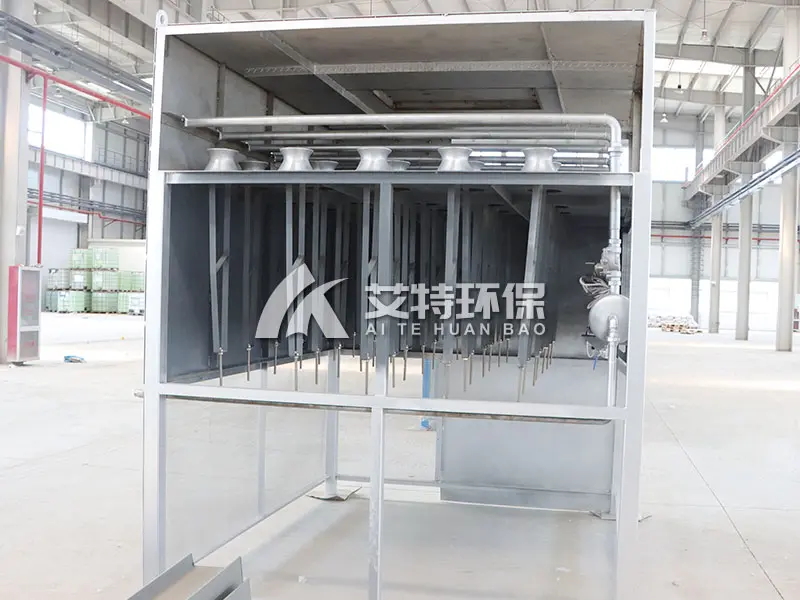

Filtration process: The dust-laden air is sucked by the air compressor and sucked from the coarse filter box of the filter filter. The clean air enters the venturi through the sealing gasket, joins the air collecting port in the clean air chamber, and is sucked by the air compressor from the clean air outlet pipe.

Self-cleaning process: After the dust-laden air is filtered, the dust is adsorbed on the filter cartridge, and the PLC performs the back-flushing self-cleaning process according to the set time sequence. Blow self-cleaning process (backflush time is 0.1-0.2 seconds). Other filter cartridges work as usual, and the dust is cleaned by backflushing.

Third,Technical parameters

Air filtration capacity: 225-4400m3/min

Initial resistance loss: ≤150Pa

Power supply: 220V

Power consumption: 100W, 150W

Filtration precision: 0.2-200μm

Backflushing air pressure: 0.1-0.2Mpa

Backflushing air volume: 0.4-0.6m3/min

Fourth,Equipment Highlights

1. Overall box structure, high structural strength

The self-cleaning air filter is an integral box-type structure with high structural strength and good sealing performance.

2. Three self-cleaning methods can be selected

The self-cleaning air filter is controlled by an intelligent distributor, and there are three ways of self-cleaning, namely (1) timing; (2) differential pressure; (3) manual.

3. High filtration efficiency

The self-cleaning air filter can filter soot particles of different sizes of 0.2-200 microns, with high filtration efficiency and high purification efficiency.

4. Flexible combination

It can be combined flexibly, and the number of units can be adjusted adaptively.

5, a variety of environmental conditions can be used

Self-cleaning air filters can not only be used in foggy and rainy seasons, but also in low-temperature freezing weather in winter and desert environments with high dust content.

6. No elbow design, easy to install

Reasonable design, no elbow design, high-rise building block combination type, easy and fast installation.

Fifth,Field of use

1. Blast furnace induced draft fan in iron and steel plant;

2. The inlet of the compressor of the oxygen generator;

3. Gas turbines and diesel engines of various capacities;

4. Air-conditioning and air supply systems for chemical fiber textile and electronic industries;

5. Centralized air-conditioning systems with high requirements for air dust content;

6. Air-conditioning air supply system for tobacco and paper industry.

As a professional air filter manufacturer, Aite has accumulated mature experience in the research and development, production and manufacture of air filter equipment. In the future, Aite will continue to increase product development and design, continue to innovate products, strictly control product quality, provide customers with perfect after-sales service, and continue to contribute to air purification.