How to clean the air filter in the dust collector?

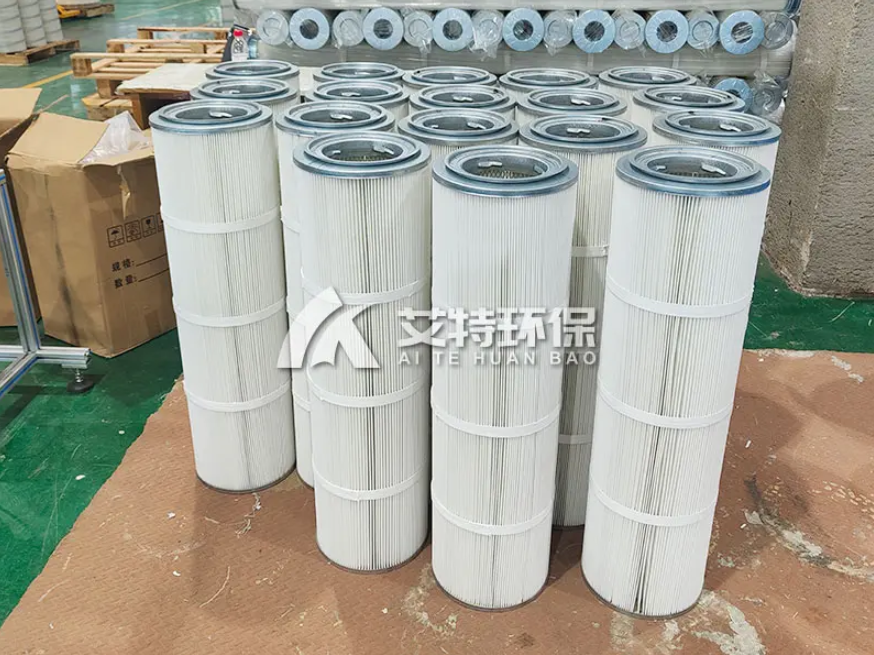

The structure of the filter barrel dust collector is composed of air inlet pipe, air exhaust pipe, box, ash hopper, dust cleaning device, diversion device, air distribution plate, filter barrel and electric control device. Barrel dust collector is widely used in food, pharmaceutical, feed, metallurgy, building materials, cement, machinery, chemical, electric power, light industry dust gas purification and dust material recovery.

The advantages of the filter cylinder dust collector

A guide plate is designed at the inlet of the dust collector, which reduces the impact of dust and gas on the filter cylinder and prolongs the service life of the filter cylinder.

The wide box structure design reduces the resistance of dust collector itself.

Reasonable man-machine design concept, convenient equipment inspection and repair and maintenance.

Advanced control system design, can always ensure the equipment under the condition of low power consumption.

How to clean the air filter cylinder in the filter cylinder?

The cleaning of the air filter in the filter barrel dust collector is realized through the pulse injection valve mechanism controlled by the sensor. When the filter barrel dust collector runs for a period of time, fine dust and dust are adsorbed on the surface of the filter material, which reduces the permeability of the filter material. The two detection heads of the differential pressure sensor are mounted on the outlet side and the intake side. When the pressure difference detected by the differential pressure sensor exceeds a certain set value, the differential pressure signal will be output. After receiving the signal, the pulse generator will start the pulse injection valve in sequence, and clean compressed air will be ejected from the valve port, so that the air will purge the dust removal filter cylinder until the pressure difference is lower than another set value. The dust adsorbed on the surface of the filter material is cleaned under the action of air flow and falls in the dust collection bucket at the lower part of the chamber. Pulse injection requires 0.4 ~ 0.6MPa of clean compressed air, and continuous and continuous air supply must be maintained during operation.

Previous article: What method can be used to solve the failure of coalescing dehydrated oil filter?

Next article:How to clean quartz sand filter?