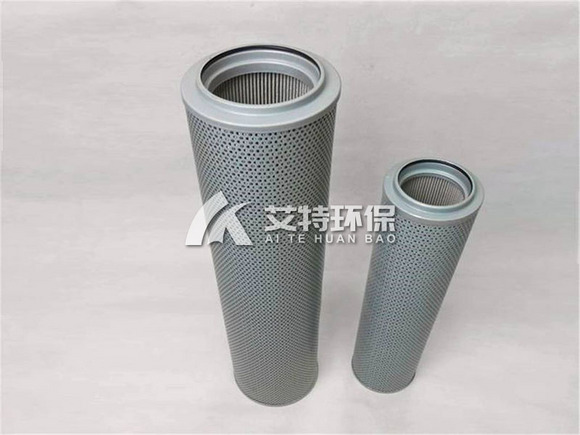

The filters are installed at the oil inlet of oil pumps to protect oil pumps and other hydraulic components, in order to avoid suction of polluting impurities, effectively control system pollution and improve the cleanliness of hydraulic systems. The filter can be installed directly on the side of the tank, the upper or the bottom, the oil suction cylinder invade the tank below the liquid level, the filter head is exposed outside the tank, and is equipped with a self-sealing valve, bypass valve, filter element pollution blocking signal device, so that the oil in the tank will not flow out when replacing the filter element and cleaning the filter element, this product is novel in design, easy to install, large oil passing capacity, small resistance, Easy to clean or replace the filter element.

The filters are installed at the oil inlet of oil pumps to protect oil pumps and other hydraulic components, in order to avoid suction of polluting impurities, effectively control system pollution and improve the cleanliness of hydraulic systems. The filter can be installed directly on the side of the tank, the upper or the bottom, the oil suction cylinder invade the tank below the liquid level, the filter head is exposed outside the tank, and is equipped with a self-sealing valve, bypass valve, filter element pollution blocking signal device, so that the oil in the tank will not flow out when replacing the filter element and cleaning the filter element, this product is novel in design, easy to install, large oil passing capacity, small resistance, Easy to clean or replace the filter element.

1. Special filter material for automobile airbag.

2. Precision filtration of hydraulic oil and lubricating oil in machinery, ships, electric power, electronics, aviation, aerospace and other fields.

3. Filtration of various high temperature and corrosive liquids in petroleum and chemical industries.

4. Chemical fiber and film industry: filtration and purification of polyester, polyamide, polyester and other polymer melts, and production of filter layers for melt and textile components.

5. Clarification and filtration of various liquids in the pharmaceutical, biological and beverage industries.

1. The air chlorine flow in the technical parameters of the filter element of rated air intake should be greater than the rated air intake of the appropriate engine.

2. The filtration material has the requirements of thickness, tension resistance, original intake resistance, filtration accuracy and so on.

3 Imported diesel engine requires air filtration accuracy of 5μm, domestic diesel engine is also less than 20μm.

4. Filter element performance test

(1) flow-resistance test -- measurement of air flow pressure loss.

(2)Original filtration efficiency test -- the dust collection efficiency of filter element can be calculated.

(3)Dust removal capacity test and cumulative efficiency test -- oral paper and domestic paper. The selected filter element must match the power, economy and reliability of the original engine

LH0060D3BN/HC Hydraulic Oil filter element

Similar ProductsVIEW MORE >