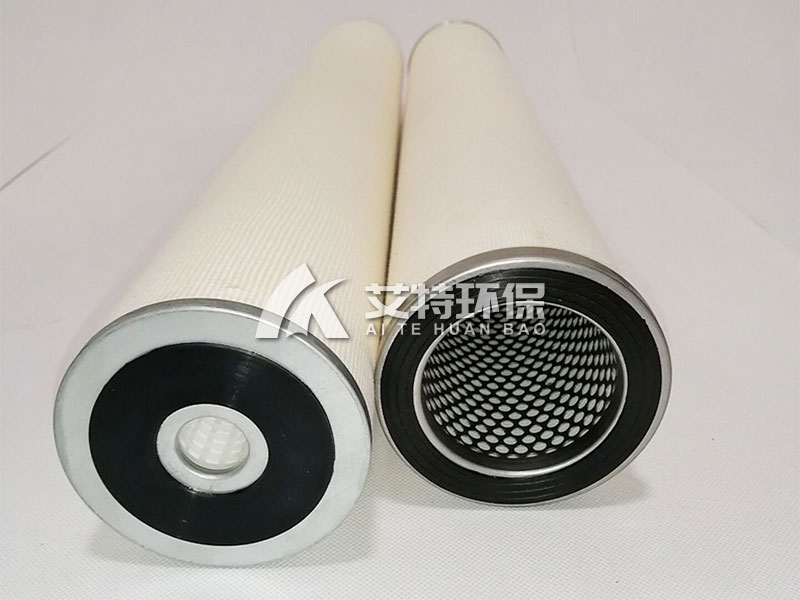

Coalescence separation filter element natural gas filter layer kerosene pipeline filter oil-water separation coalescence filter element.Oil-water separation filter element is mainly designed for oil-water separation, it contains two kinds of filter element, namely: poly filter element and separation filter element.

Coalescence separation filter element natural gas filter layer kerosene pipeline filter oil-water separation coalescence filter element.Oil-water separation filter element is mainly designed for oil-water separation, it contains two kinds of filter element, namely: poly filter element and separation filter element.

Material: stainless steel

Filter element form: Folding filter element

Purpose: separation of oil and water

Scope of application: pipeline gas transmission device

Applicable object; Lubricating oil, natural gas, oil, cutting fluid, grinding oil, etc

Operating temperature :60 (℃)

Maximum working pressure difference :5 (MPa)

Filtration accuracy :1-20 um

Inlet and outlet diameter :1 (mm)

Properties: alkali resistance, low temperature resistance, high temperature resistance, acid resistance

Raw water pressure :5 (KG/c㎡)

In the oil water removal system, the oil into the coalesce separator, first flow through the coalesce filter element, coalesce filter element to filter out solid impurities, and the very small water droplets coalesce into larger water beads. Most of the coalesced water droplets can be separated from the oil and removed by their own weight and settled into the collection tank. Then the oil flows through the separation filter element, because the separation filter element has good oil hydrophobicity, so as to further separate the water, and finally, clean, water-free oil flows out of the coalescence separator. The oil first enters the lower part of the filter shell by the inlet pipe, and then flows through the filter element from outside to inside. At this time, the coarse particles will immediately precipitate and be released by the drain valve. The smaller particles are intercepted by the filter element.

Finally, after the clean oil is collected by the filter element tray, it flows out of the coalescent separator from the outlet pipe. With the increase of the amount of treated oil, the pollutants deposited on the filter element will cause the pressure difference of the coalescent to rise. When the pressure difference rises to 0.15Mpa, it indicates that the coalesce filter element has been blocked and should be replaced. The oil flows into the primary tray from the inlet of the coalesce separator, and then diverts into the primary filter element. After filtration, demulsification, water molecule growth and coalesce process, the impurities are trapped in the primary filter element, the coalesce water beads settle in the precipitation tank, the oil enters the secondary filter element from outside to inside, gathers in the secondary tray, and flows out from the outlet of the coalesce separator. The material of the two stage filter element has hydrophobicity, the oil can pass smoothly, the free water is blocked in the filter element, flows into the precipitation tank, and is discharged through the pollution valve.

PCHG-536 Natural gas filter element

Similar ProductsVIEW MORE >