PALL oil filter PFC8300-100-YV is produced by foreign Pall company. Later, after the improvement of domestic industrial technology, a replacement model is produced. The oil filter is manufactured by Aite Environmental Production.

PALL oil filter PFC8300-100-YV is produced by foreign Pall company. Later, after the improvement of domestic industrial technology, a replacement model is produced. The oil filter is manufactured by Aite Environmental Production.

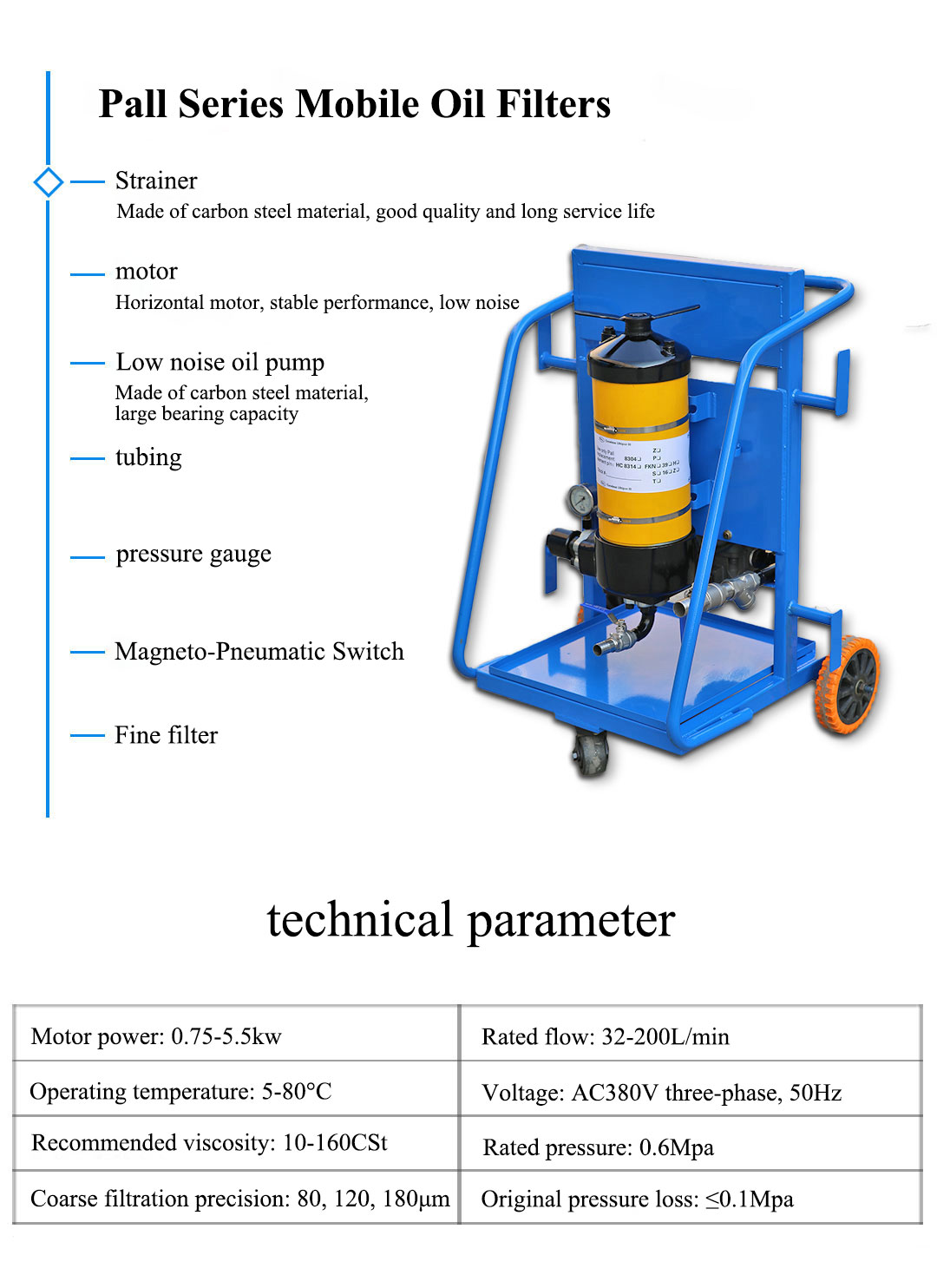

PFC8300-100-YV PFC8300-100-YV Poul filter is composed of an oil tank and a hand-pushed bracket, with high quality motor and filter materials can achieve the removal of impurities and filtration of oil. The effect is remarkable.

Rated flow: 100L/min

Rated pressure: 1.0MPa

Motor power: 4KW

Power supply: 380V three-phase

Filtration accuracy βx=1000 (X=2.5, 5, 7, 12, 22μm)

Medium viscosity: ≤100cst

Working medium: mineral oil, emulsion, water - ethylene glycol, phosphate ester anti - combustion liquid

Equipment weight kg: 192

Dimensions: 1000×810×1610

1. Lock the differential pressure alarm to prevent false alarm during cold start.

2. Acousto-optic differential pressure alarm prompts that the filter element is blocked and needs to be replaced.

3. Filter with bypass valve to avoid system flow interruption.

4. Motor phase fault protection.

5. Oil inlet coarse filter protects oil pump and prolongs the service life of filter element.

6. The outlet diffuser controls the direction and velocity of liquid return to prevent swirling air from mixing into the tank.

7. Add oil collecting pan and tubing fixing device to reduce environmental pollution.

8. Oil pump with overflow valve.

9. Universal wheel makes movement more flexible and convenient.

Before switching on the power supply each time, confirm whether the power supply voltage is consistent with the requirements of the machine.

After power is connected, the power indicator is normally on, and the alarm indicator (differential pressure, phase sequence) and buzzer do not work; If not, please press

Perform the following steps in the Troubleshooting section.

The inlet and outlet ball valves should be opened before starting.

After starting, if you find abnormal vibration and noise, please follow the steps in the Troubleshooting section.

After the machine is used for a period of time, if the oil seal wear exceeds the design standard, oil leakage will occur at the end of the oil pump shaft. Timely replacement of the sealing ring

Pall oil filter PFC8300

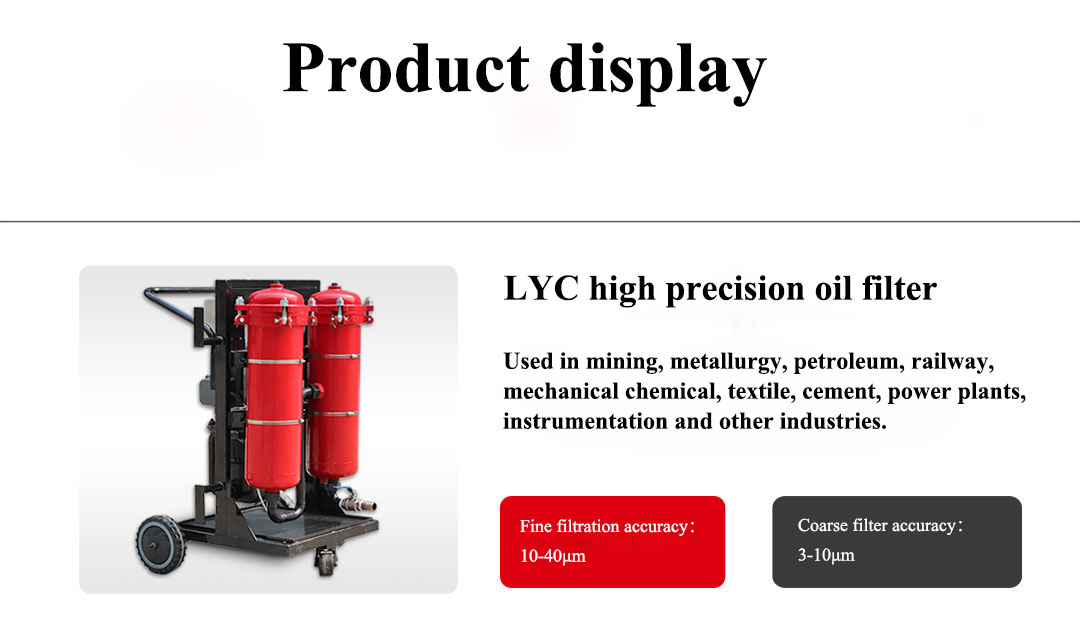

Similar ProductsVIEW MORE >