The filter material of LPFC8314-150 Oil Filter is made of fiber and resin, and has a fixed process structure. The trapped pollutants will not be discharged due to the pulsation of flow and pressure difference.

The filter material of LPFC8314-150 Oil Filter is made of fiber and resin, and has a fixed process structure. The trapped pollutants will not be discharged due to the pulsation of flow and pressure difference.

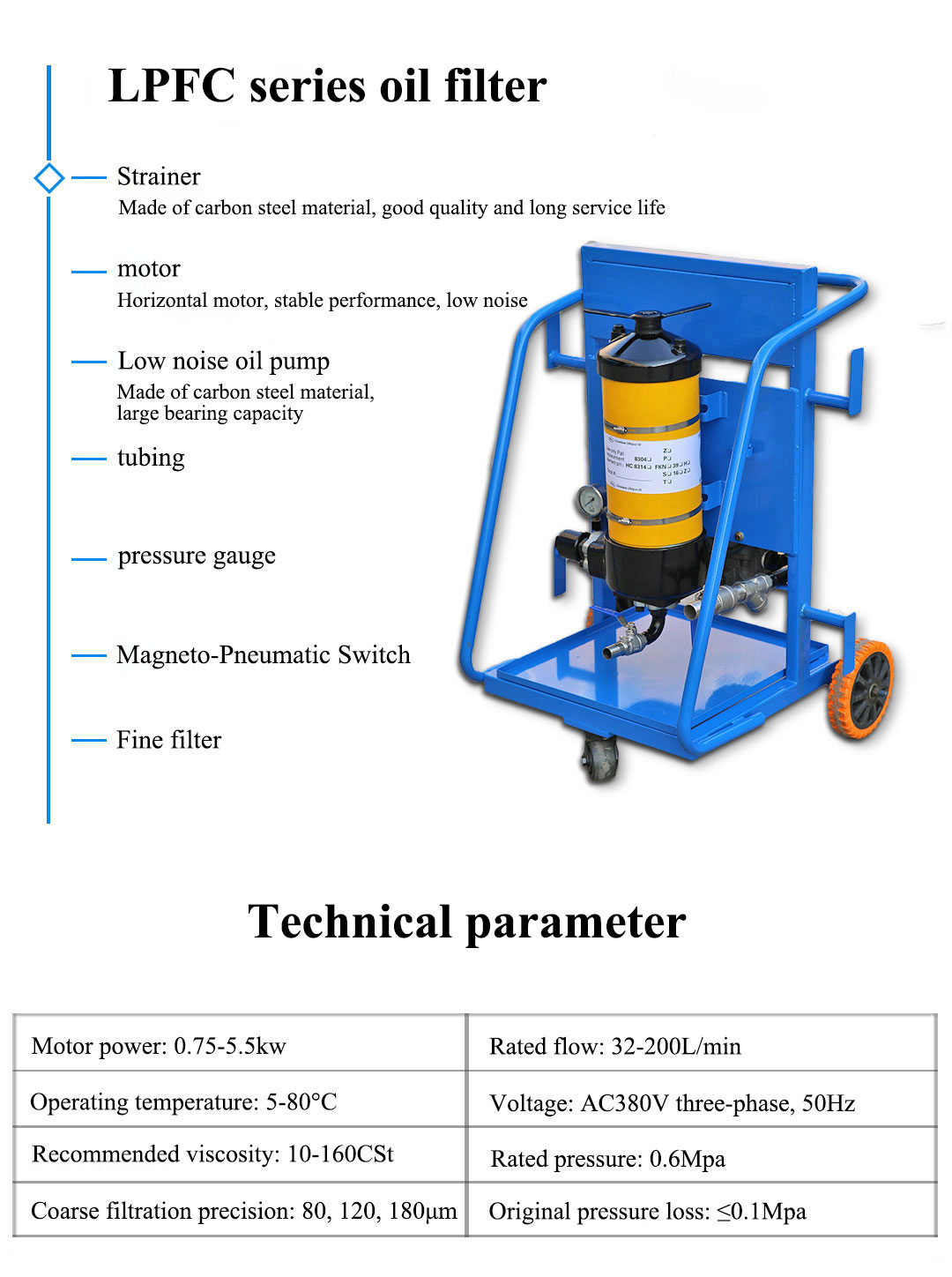

1. The overall performance of LPFC8314-150 Oil Filter is stable and the strength is improved.

2. Improve the practicability of the oil filter.

3. The oil filter adopts gear pump, which has low noise and strong oil absorption capacity.

4. The wheels are flexible and no noise.

5. The liquid outlet is equipped with a diffuser to prevent gyration.

6. The suction port strainer protects the oil pump and prolongs the service life of the filter element.

7. The liquid outlet diffuser controls the direction and flow rate of liquid return to prevent the swirl flow from mixing air into the fuel tank.

8. Universal wheels make the movement more flexible and convenient.

9. Add oil collecting pan and oil pipe fixing device to reduce environmental pollution.

10. The oil pump has a relief valve.

1. Before turning on the power each time, it should be confirmed whether the power supply voltage conforms to the requirements of the machine.

2. After the power is turned on, the power indicator light is on under normal circumstances, and the alarm indicator (pressure difference, phase sequence) and the buzzer do not work; if it is not normal, please handle it according to the fault.

3. Before starting, the inlet and outlet ball valves should be opened.

4. After starting, if abnormal vibration and noise are found, please handle it according to the fault.

5. After the machine is used for a period of time, if the wear of the oil seal exceeds the design standard, there will be oil leakage at the shaft end of the oil pump, and the sealing ring should be replaced in time.

LPFC8314-150 Oil Filter

Similar ProductsVIEW MORE >