HC8400FKN39H filter element should be installed at the oil suction port of the pump: the oil suction circuit of the pump is generally equipped with a surface type oil filter, which aims to filter out large impurity particles to protect the hydraulic pump.

HC8400FKN39H filter element should be installed at the oil suction port of the pump: the oil suction circuit of the pump is generally equipped with a surface type oil filter, which aims to filter out large impurity particles to protect the hydraulic pump. In addition, the filtration capacity of the oil filter should be more than twice of the pump flow, and the pressure loss should be less than 0.02MPa.

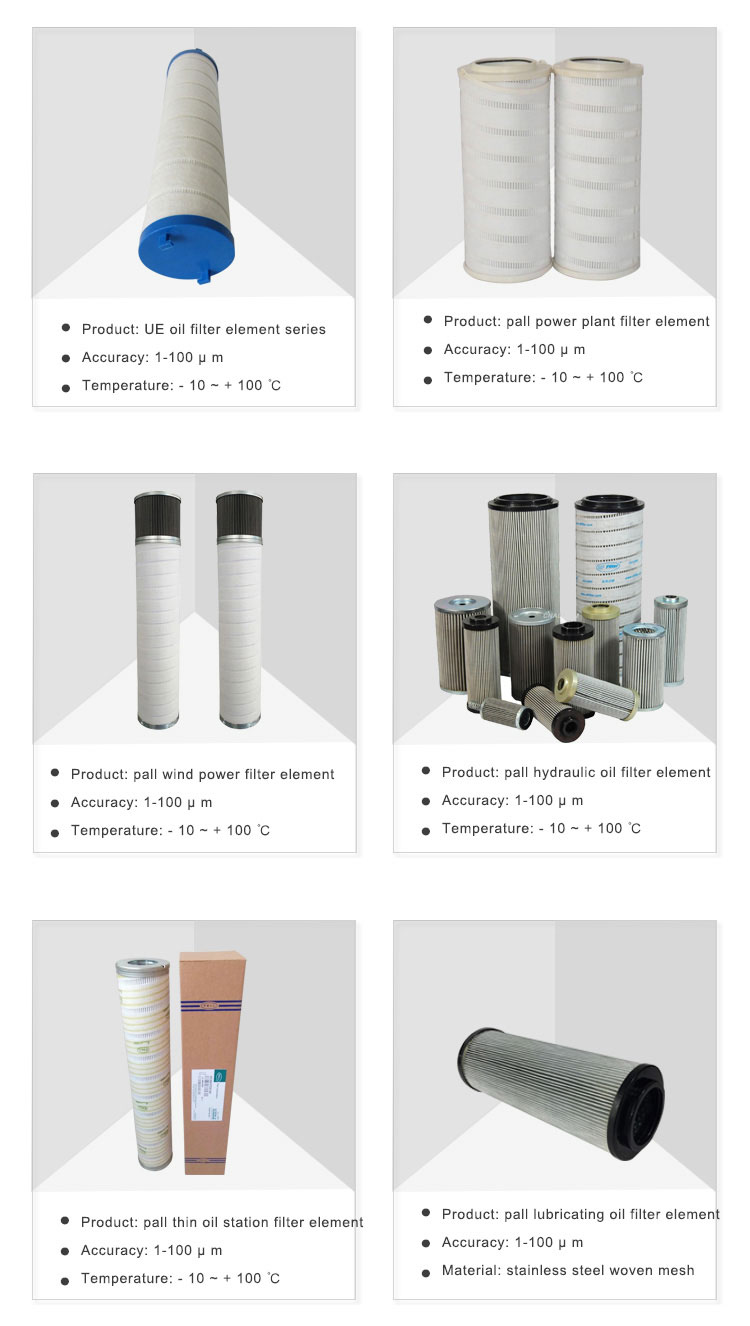

Medium: general hydraulic oil phosphoric acid hydraulic oil emulsion water - diol

Material: Glass fiber filter paper -BN stainless steel woven mesh -W wood pulp filter paper -P stainless steel sintered mesh -V

Filtration accuracy: 1μ-100μ

Working pressure: 21bar-210bar

Working medium: general hydraulic oil, phosphoric acid hydraulic oil, emulsion, water - glycol

Operating temperature: -30℃ ~ +110℃

Sealing material: fluorine rubber ring butyl rubber

According to the different raw materials used, the service life of the filter element will be different. With the extension of the use time, the impurities in the water will block the filter element, and the activated carbon filter element will be absorbed and saturated. Therefore, generally speaking, PP filter element needs to be replaced in 3 months, and activated carbon filter element needs to be replaced in 6 months. Because hollow fiber can not be cleaned, it is generally placed in the back end of PP cotton and activated carbon, otherwise it is easy to block, and it needs to be replaced for 1-2 years when used as the end of water purification equipment to remove bacteria.

1. Petrochemical: separation and recovery of products and intermediate products in the process of oil refining and chemical production, liquid purification, tape, CD and photographic film purification in manufacturing, oilfield well water and natural gas particle removal filtration.

2, textile: polyester melt in the process of drawing purification and uniform filtration, air compressor protection filtration, compressed gas removal of oil and water.

3, electronics and pharmaceutical: reverse osmosis water, deionized water pretreatment filtration, washing liquid and glucose pretreatment filtration.

4, thermal power and nuclear power: gas turbine, boiler lubrication system, speed control system, bypass control system oil purification, feed water pump, fan and dust removal system purification.

5, mechanical processing equipment: paper machinery, mining machinery, injection molding machine and large precision machinery lubrication system and compressed air purification, tobacco processing equipment and spraying equipment dust recovery and filtration.

6.Railway internal combustion engine and generator: lubricating oil and oil filtration.

7, automobile engine and construction machinery: internal combustion engine with air filter, oil filter, fuel oil filter, construction machinery, ships, trucks with all kinds of hydraulic oil filter, diesel filter, water filter.

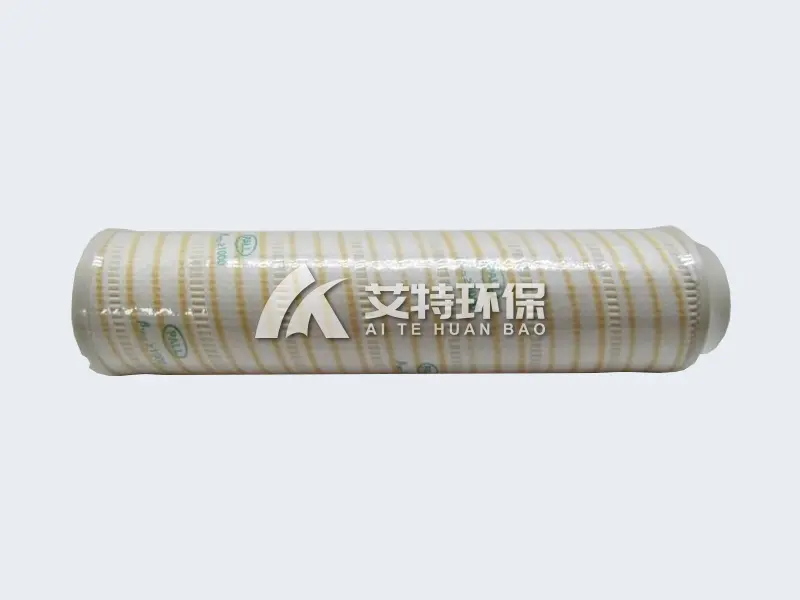

HC8400FKN39H filter element

Similar ProductsVIEW MORE >