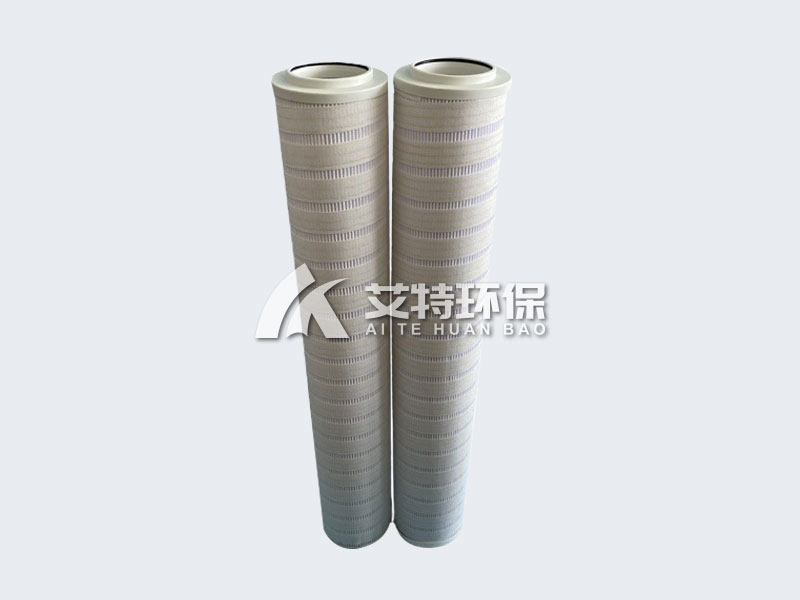

Filter element HC0101FKS36H consists of shell, multi-element filter element, backwash tissue, and differential pressure controller.

Filter element HC0101FKS36H consists of shell, multi-element filter element, backwash tissue, and differential pressure controller. The diaphragm in the shell divides its inner cavity into upper and lower cavities, and the upper cavity is equipped with multiple filter elements, which makes full use of the filter space and significantly reduces the volume of the filter. Rinse the suction cups.

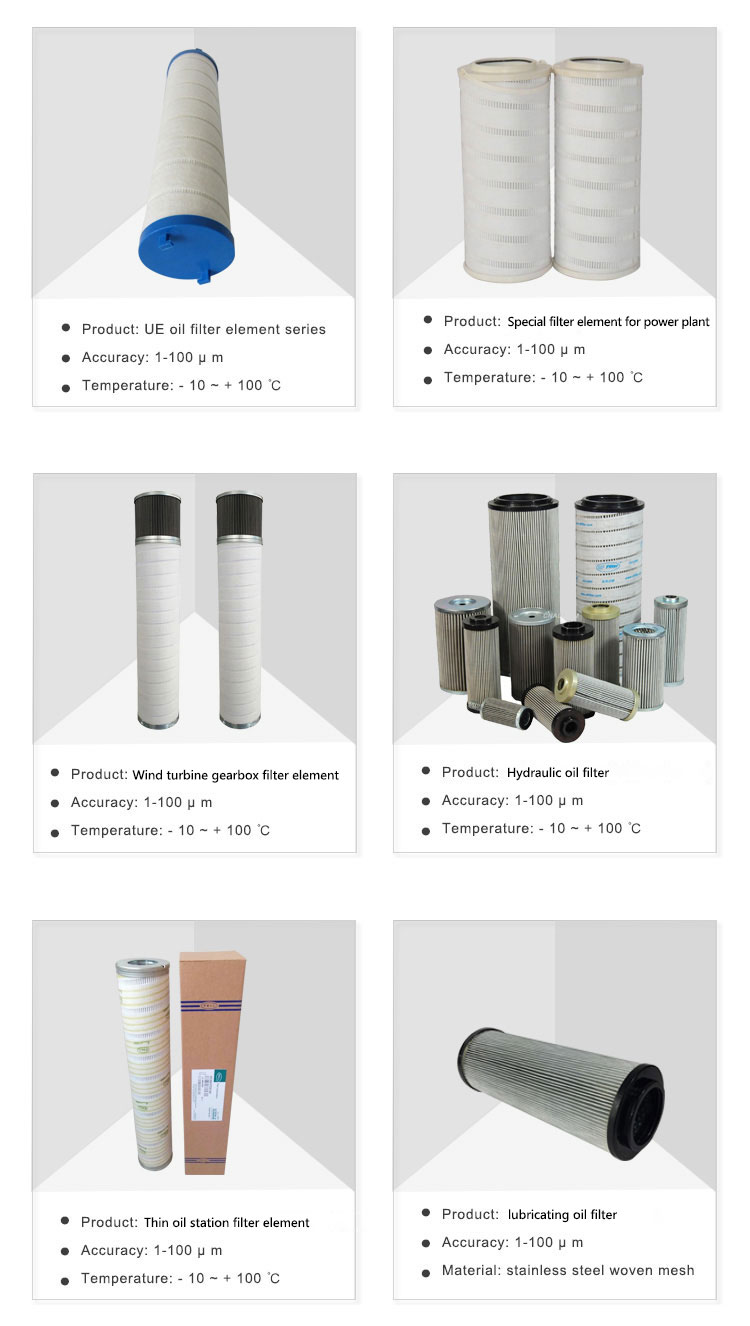

Material: glass fiber filter paper-BN stainless steel woven mesh-W wood pulp filter paper-P stainless steel sintered mesh-V

Filtration precision: 1μm~100μm

Working pressure: 21bar-210bar

Working medium: general hydraulic oil, phosphate ester hydraulic oil, emulsion, water-glycol

Working temperature: -30℃~+110℃

Sealing material: fluorine rubber ring, nitrile rubber

1. The filter element should be installed at the suction port of the pump:

Generally, a surface oil filter is installed on the suction road of the pump to filter out large impurity particles to protect the hydraulic pump. In addition, the filtering capacity of the oil filter should be more than twice the flow rate of the pump, and the pressure loss should be less than 0.02MPa.

2. The filter element is installed on the outlet oil road of the pump:

The purpose of installing the oil filter here is to filter out the contaminants that may invade the valve and other components. Its filtration precision should be 10 ~ 15μm, and it can withstand the working pressure and impact pressure on the oil circuit, and the pressure drop should be less than 0.35MPa. At the same time, a safety valve should be installed to prevent the oil filter from being blocked.

3. The filter element is installed on the oil return road of the system: this installation acts as an indirect filter. Generally, a back pressure valve is installed in parallel with the filter. When the filter is blocked and reaches the corresponding pressure value, the back pressure valve opens.

4. The filter element is installed on the branch oil circuit of the system.

5. The filter element separate filtration system: a large hydraulic system can be specially equipped with a filtration circuit composed of a hydraulic pump and an oil filter.

Filter element HC0101FKS36H

Similar ProductsVIEW MORE >