HC0101FKN36H filter element is composed of shell, multi-element filter element, backwashing organization, and differential pressure controller.

HC0101FKN36H filter element is composed of shell, multi-element filter element, backwashing organization, and differential pressure controller. The diaphragm in the shell divides its inner cavity into upper and lower cavities, and the upper cavity is equipped with multiple filter elements, which makes full use of the filter space and significantly reduces the volume of the filter. Rinse the suction cups.

When working, the turbid liquid enters the lower cavity of the filter through the inlet, and enters the inner cavity of the filter element through the baffle hole. The impurities in the gap of the HC0101FKN36H filter element are trapped, and the clean liquid passes through the gap to the upper chamber and is sent out from the outlet.

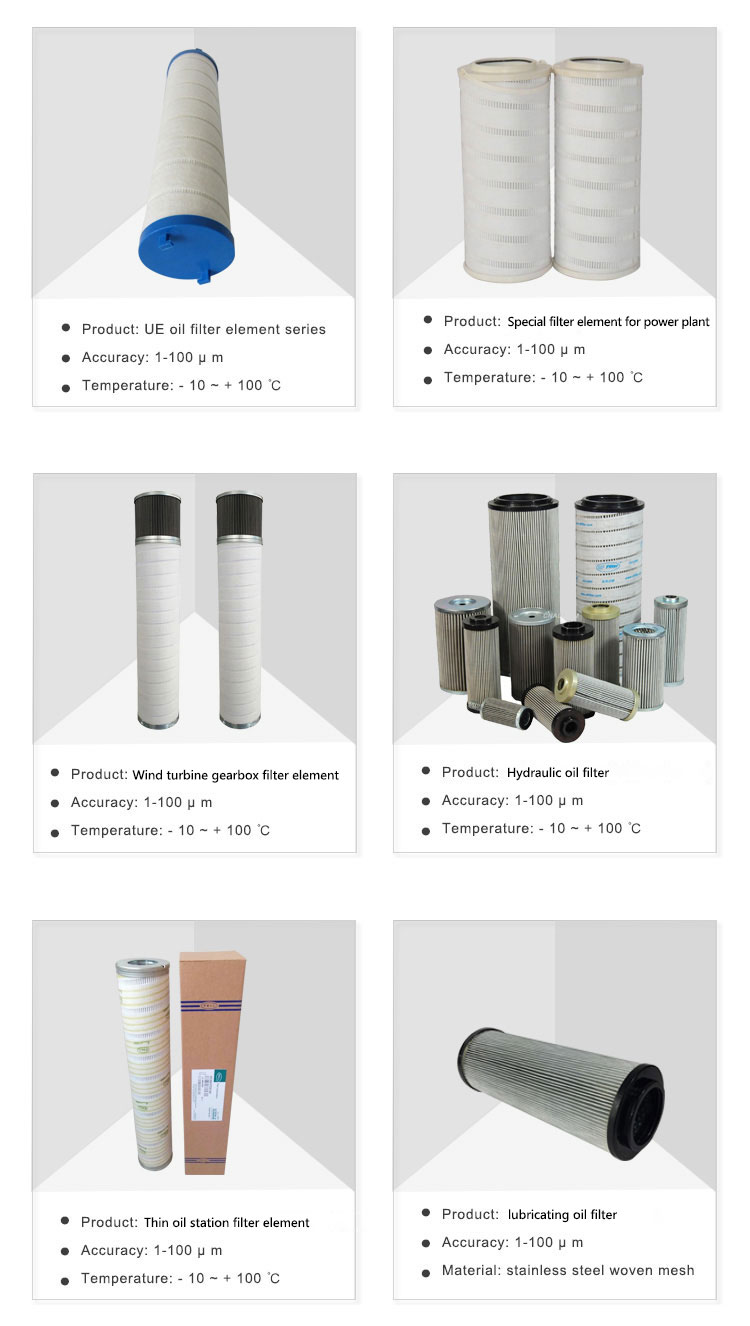

Material: glass fiber filter paper-BN stainless steel woven mesh-W wood pulp filter paper-P stainless steel sintered mesh-V

Filtration precision: 1μm~100μm

Working pressure: 21bar-210bar

Working medium: general hydraulic oil, phosphate ester hydraulic oil, emulsion, water-glycol

Working temperature: -30℃~+110℃

Sealing material: fluorine rubber ring, nitrile rubber

1. High flow medium can pass through the filter material, low voltage loss and long service life.

2. The structure of the high-flow filter element in and out makes it easy to replace the filter element, and at the same time, the pollutants are trapped outside the filter element.

3. There is a pp support frame inside the filter element, which can withstand a pressure difference of 0.245MPa.

HC0101FKN36H filter element

Similar ProductsVIEW MORE >