Whenthegasistransportedinthepipeline,partofthesaturatedsteamandmechanicalwaterwillbeseparated.

When the gas is transported in the pipeline, part of the saturated steam and mechanical water will be separated. It will adversely affect the use of gas transmission, gas pipeline facilities and users. Therefore, it is necessary to drain the condensed water from the pipeline in time. A dry gas drain is a device specially designed to drain condensate water from a gas pipeline.

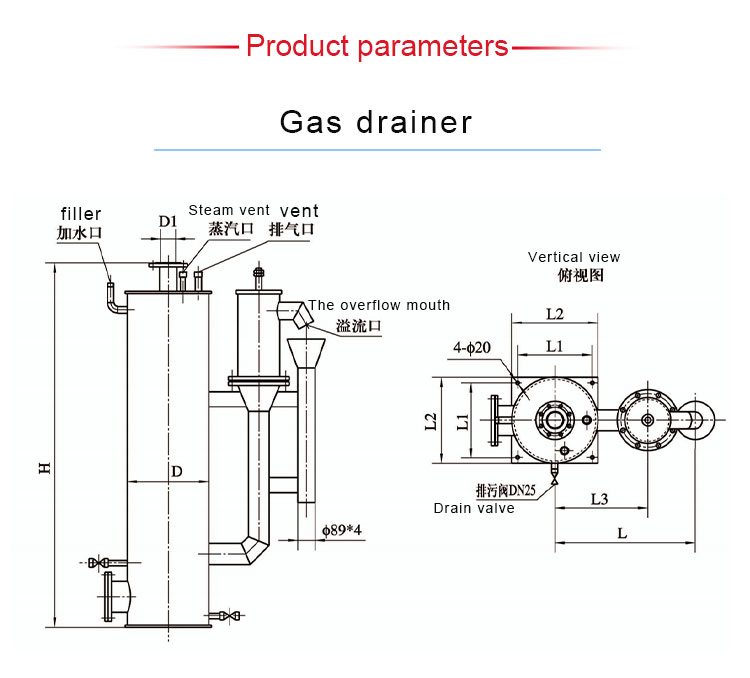

The dry type gas drain is mainly to connect the anti-breakdown non-leakage gas drain into the pipeline for conveying gas. The condensed water in the gas pipeline enters the high pressure chamber of the drain through the drain pipe, and then passes through the connecting pipeline of the high and low pressure chambers on the clapboard. Enter the low pressure chamber of the drain to collect the condensed water, pass the water seal and automatically discharge the condensed water in the gas pipeline to ensure the normal operation of the equipment. When the gas pipe network pressure fluctuates or the water level of the drainer is abnormally low due to gas breakdown, under the action of the gas shock, the anti-leakage device is triggered to close the overflow port to prevent the gas from leaking out and ensure the normal operation of the equipment.

1. It can realize continuous drainage.

2. It can prevent gas leakage very well.

3. Has good breakdown resistance.

4. It has the ability to release pressure for security.

5. It is easy to clean up the ash and sludge entering the drain.

6. Low failure rate and high reliability.

7. The operation is simple and the maintenance workload is small.

8. Simple structure, no moving parts.

9. It is convenient to observe the operation status of the drain.

10. Low manufacturing, operation and maintenance costs.

11. It is easy to collect and treat sewage and sludge, without energy consumption, and has good energy saving and environmental protection performance.

dry gas drain

Similar ProductsVIEW MORE >