Precision filter, also known as the security filter, is generally set before the pressure vessel to remove fine particles with turbidity of more than 1 degree to meet the requirements of the following process on water; It is also sometimes placed at the end of the entire water treatment system to prevent fine particles (such as broken resin) from entering the finished water

Precision filter device (also known as security filter) mostly use stainless steel shell, internal filter element (such as PP cotton), mainly used in multi-media pretreatment filtration, reverse osmosis, ultrafiltration and other membrane filtration equipment before. Used to filter out the fine matter after multi-media filtration (such as tiny quartz sand, activated carbon particles, etc.), to ensure the accuracy of water filtration and protective film filtration elements from large particulate matter damage. The precision filter element precision grade installed in the precision filter device can be divided into 0.5μs,1μs,5μs,10μs, etc. Different filtration precision is selected according to different use occasions, in order to ensure the accuracy of the effluent and ensure the safety of the membrane element after the stage.

Using PP cotton, nylon, meltblowout and other different materials as the filter element, remove the small suspended matter in the water, bacteria and other impurities, so that the raw water quality to meet the requirements of reverse osmosis membrane water intake.

Security filter is a precision filter, its working principle is to use PP filter element 5μm pores for mechanical filtration. The residual trace suspended particles, colloids, microorganisms, etc. in the water are intercepted or absorbed in the surface and pores of the filter element. With the growth of water production time, the filter element due to the pollution of the interception, its running resistance gradually rises, when running to the inlet and outlet water pressure difference reaches 0.1MPa, the filter element should be replaced. The main advantages of the security filter are high efficiency, low resistance and easy replacement.

The security filter adopts the formed filter material. Under the action of pressure, the stock liquid passes through the filter material, the filter slag stays on the tube wall, and the filtrate flows out through the filter material, so as to achieve the purpose of filtration. Structure: filter cloth, filter screen, filter piece, sintered filter tube, wire wound filter element, meltjet filter element, etc. Because of the different filter material, filter aperture is not the same. Precision filtration is a kind of filtration between sand filtration (coarse filtration) and ultrafiltration, and the filter aperture is generally in the range of 0.5~120μm. The same form of filter material, according to the size of the appearance can be divided into different specifications. Wire-wound filter element (also known as honeycomb filter element) has two kinds: one is polypropylene fiber - polypropylene skeleton filter element, the highest use temperature of 60℃; The other is absorbent cotton fiber - stainless steel skeleton filter element, the highest use temperature 120℃. Melt-blown filter element is made of polypropylene as raw material, which is formed by melt-blown process. The maximum working temperature is 60℃. Precision filtration can remove suspended solids, some colloidal substances and small particulate matter in water.

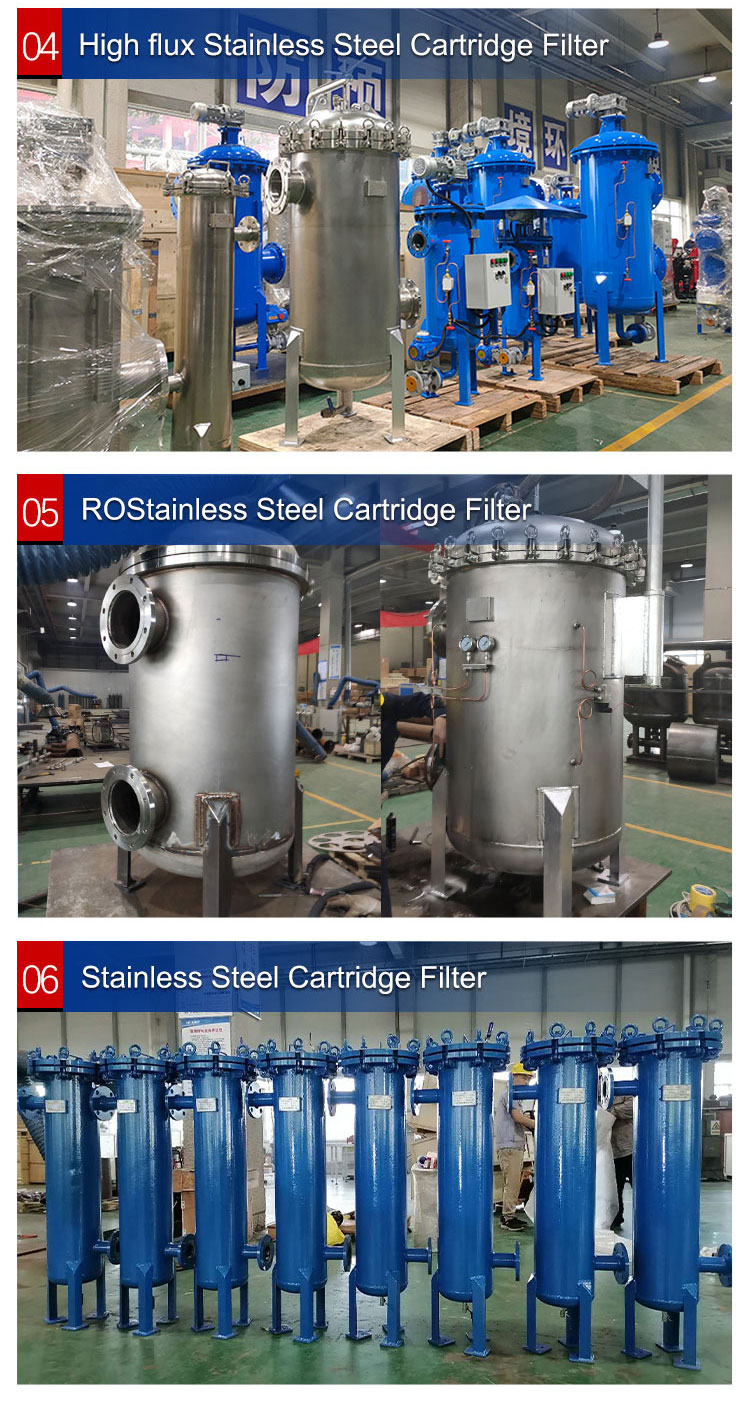

High throughput stainless steel security precision filter

Similar ProductsVIEW MORE >