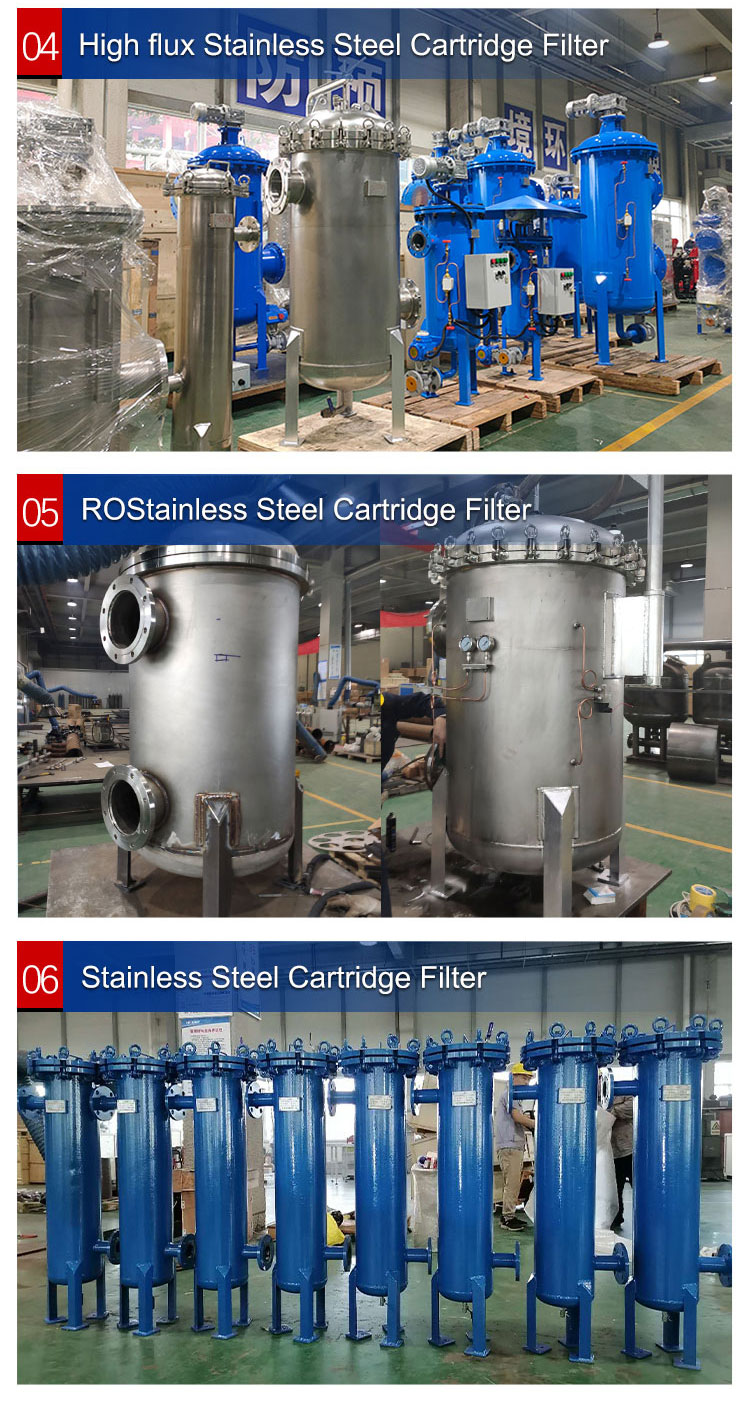

Solid-liquid separation security filter is used for solid-liquid separation of all kinds of suspension, high environmental requirements, high filtration precision of liquid medicine filtration, a wide range of application, suitable for medicine, food, chemical, environmental protection, water treatment and other industrial fields.

The security filter is also known as the precision filter, the shell is generally made of stainless steel, and the interior uses PP melt-blowout, wire burning, folding, titanium filter element, activated carbon filter element and other tubular filter element as the filter element. According to different filter media and design process, different filter elements are selected to meet the requirements of water quality. The body can also choose the quick installation type, in order to convenient and quick replacement of filter element and cleaning.

1. Can remove water, oil mist, solid particles, remove 0.01μm particles and above, oil mist concentration is controlled at 0.01ppm/wt;

2. Reasonable structure, small volume, light weight;

3. With protective cover plastic shell and aluminum alloy shell can choose microporous precision filter element

4. Three stage purification treatment, long service life.

1. The core component of the precision filter is the filter element, which is easily damaged and needs special protection.

2. Precision filter works for a long time, it will block a certain amount of impurities, which will reduce the working rate, so it is necessary to clean frequently, and clean the filter element.

3. in the cleaning process to pay special attention to the cleaning of the filter element, do not deformation or damage, otherwise it will lead to the reduction of filtration accuracy, can not meet the production requirements.

4. If the filter element is deformed or damaged, it should be replaced immediately.

5. some precision filter element, can not be used repeatedly, such as bag filter element, polypropylene filter element, etc.

1. import and export diameter

In principle, the filter inlet and outlet diameter should not be smaller than the matching pump inlet diameter, generally consistent with the inlet pipe diameter.

2. Nominal pressure

Determine the pressure level of the filter according to the possible high pressure of the filter line.

3. the selection of the number of holes

Mainly consider the size of impurities to be intercepted, according to the medium process requirements. Various specifications screen can intercept the particle size check the table "screen size".

4. Filter material

Generally, the material of the filter is the same as that of the process pipe connected. For different service conditions, cast iron, carbon steel, low alloy steel or stainless steel filters can be considered.

5. filter resistance loss calculation

For water filters, the pressure loss is 0.52 ~ 1.2kpa at the rated flow rate.

Solid-liquid separation security filter

Similar ProductsVIEW MORE >