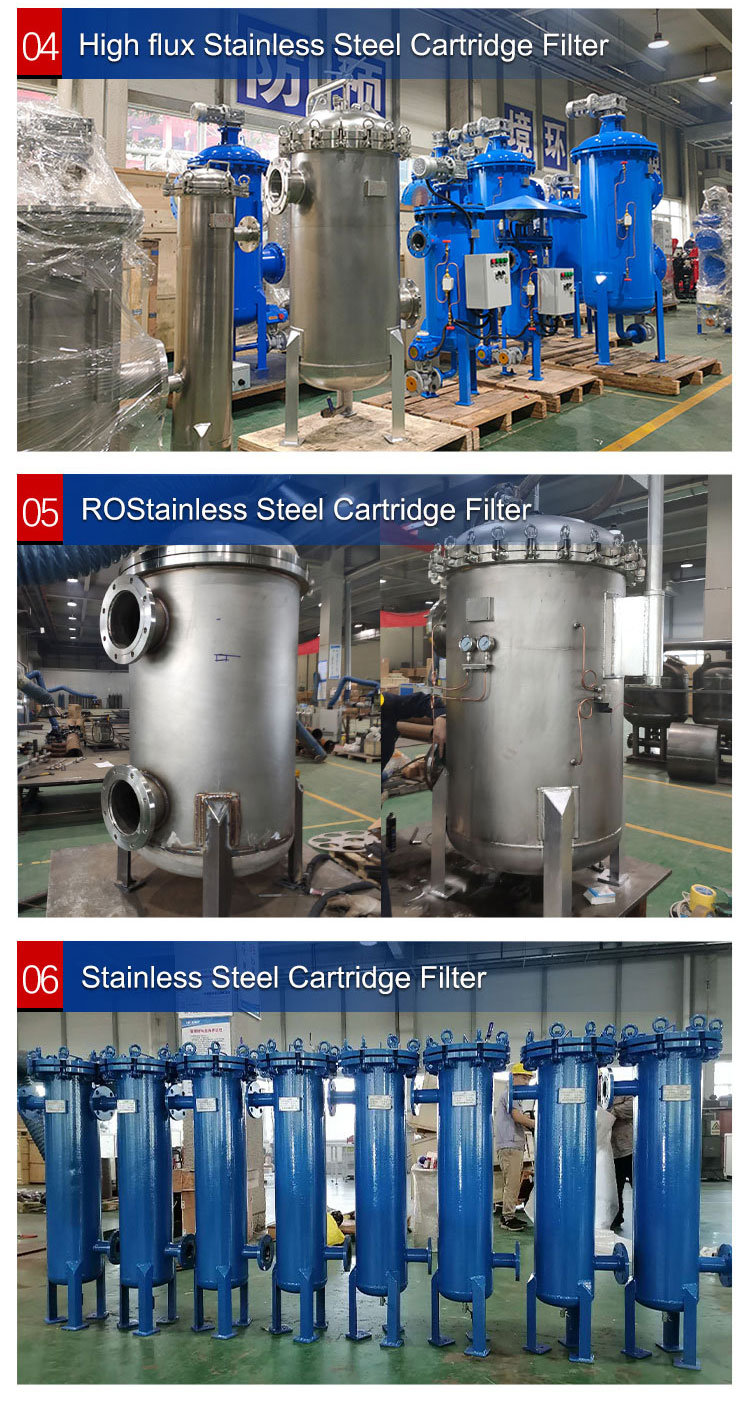

Large flow filter (EDI security filter) is installed on the pipeline can remove all kinds of solid particle pollutants in the fluid machine, can achieve the purpose of extending the service life of components, improve the stability of the system operation. The biggest feature of this series of filter is that it has a self-sealing device. When replacing the filter element, it only needs to rotate 90° when loosening the flange, which can achieve the self-sealing requirements to prevent fluid overflow and facilitate the replacement of the filter element.

EDI security filter for large diameter and high flow rate pipeline and development, its core using stainless steel folding filter, relative to the competitors ordinary punching basket filter and rod folding filter multiple times the area. Its more than 50% opening rate and straight-through structure, combined with the maximum flow rate and minimum pressure difference, greatly reducing the overall size and weight, when the filter is out of use, only one person can clean and maintain.

EDI security filter is mostly made of stainless steel shell, internal filter element (such as PP cotton), mainly used in multi-media pretreatment filtration, reverse osmosis, ultrafiltration and other membrane filtration equipment before. Used to filter out the fine matter after multi-media filtration (such as tiny quartz sand, activated carbon particles, etc.) to ensure the accuracy of water filtration and protective film filtration elements from large particulate matter damage. The precision filter element precision grade installed in the precision filter device can be divided into 0.5μs,1μs,5μs,10μs, etc. Different filtration precision is selected according to different use occasions, in order to ensure the accuracy of the effluent and ensure the safety of the membrane element after the stage. Using PP cotton, nylon, meltblowout and other different materials as the filter element, remove the small suspended matter in the water, bacteria and other impurities, so that the raw water quality to meet the requirements of reverse osmosis membrane water intake.

EDI security filter is a kind of filter which uses the filter element as the filter medium and makes the liquid-solid separation by the effect of pressure. The method of using filter element for liquid-solid separation belongs to the microporous filtration technology, which is mainly suitable for the material with solid particles of 0.5 ~ 10μm or the material with particles larger than 0.5μm but non-rigid, easy to deform, and difficult filtration material with large viscosity between particles or between particles and filter medium. The liquid to be filtered is pressed into the filter by the filter inlet, and filtered into the clarified liquid through the filter layer from the outside through the filter element, and then discharged through the outlet. Impurities are intercepted in the deep and surface of the filter element, so as to achieve the purpose of liquid filtration, but the use time of the filter element should not be too long, because the filter element is easy to breed bacteria.

1. Nanofiltration (NF), ultrafiltration (UF), reverse osmosis (RO), electron membrane deionization (giant D,) and other systems security filtration;

2. Pharmaceutical injection, infusion, eye drops, Chinese herbal medicine liquid filtration, biological preparation extraction, purification, concentration;

3. High purity water pre-filtration for electronics, microelectronics, semiconductor industry;

4. Oilfield reinjection water, boiler replenishing water, chemical reagents, liquid organic products, high purity chemicals, concentrated drugs and other filtration;

5. Purified drinking water, mineral water, fruit juice, tea drinks, health drinks filtration;

6. Liquor, wine, beer, rice wine and other fruit wine filtration, pure draft beer sterilization filtration (instead of pasteurization);

7. Pretreatment filtration or security filtration in the process of production and domestic wastewater treatment and water recycling;

8. Others such as biological engineering, oil refining, printing and dyeing, textile industry water supply and wastewater treatment, research and experimental filtration.

EDI security filter

Similar ProductsVIEW MORE >