WorkingprincipleAftertheaerodynamicequipmentinhalesdust-containingair,itwillcausewearandtearoftheequ

After the aerodynamic equipment inhales dust-containing air, it will cause wear and tear of the equipment, and the inhaled dust will scale on the surface of the fan blades, resulting in a decrease in the dynamic balance accuracy of the rotor in the equipment, and its working life is greatly shortened. Harmful chemical components can cause equipment to rust and corrode. Therefore, aerodynamic equipment must be equipped with high-precision air filters. ZKL series self-cleaning air filters are improved and perfected in the air intake requirements of similar air compressors at home and abroad. At present, the product performance fully meets the air intake requirements of industrial gas turbine blast furnace blast air compressors.

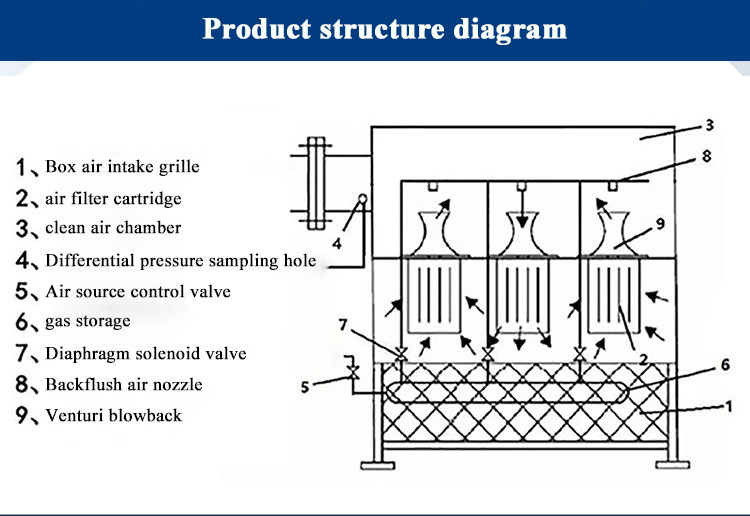

The dust-laden air is sucked by the air compressor, sucked from the first-stage coarse filter box ①, and passed through a high-efficiency filter. Filter cartridge ②, due to the combined effects of gravitational inertia, diffusion, contact retention, etc., the dust is adsorbed on the high-efficiency filter cartridge On the upper side, clean air enters the venturi ④ through the gasket garden ③, enters the clean e-room ⑤ and joins the air collecting port ⑥, and then flows from the net The air outlet pipe ⑦ is sucked by the air compressor.

After the dust-laden air is filtered, the dust is adsorbed on the high-efficiency filter cartridge, and the PLC is set according to the set time. The process of backflushing and self-cleaning is carried out in sequence. When the resistance loss value exceeds 600 Pa, the backflushing self-cleaning process is controlled by the PLC according to the sequence of differential pressure. Cleaning process (backflushing time is 0.1-0.2 seconds). Other high-efficiency filter cartridges work as usual, and the dust is blown back down

| Project\Specifications | ATZK225 | ATZK330 | ATZK380 | ATZK500 | ATZK625 | ATZK910 | ATZK1000 | ATZK1250 | ATZK1500 |

| Air filter volume (m3/min inhalation state) | 220 | 300 | 380 | 500 | 625 | 910 | 1000 | 1250 | 1500 |

| structure, single layer | single layer | ||||||||

Initial resistance loss Pa | ≤150 | ||||||||

| Filtration accuracy (um/efficiency%) | ≥ 1/99.96 | ||||||||

| ≥ 2/99.99 | |||||||||

| ≥ 3/100 | |||||||||

| Power consumption W | 100 | 150 | |||||||

| Power AC | 220V | ||||||||

| Backflushing gas volume m3/min | 0.1 | 0.2 | |||||||

| Backflushing pressure Mpa | 0.4-0.6 | ||||||||

| Dimensions (m) | 1.5 | 1.8 | 2.1 | 2.1 | 2.1 | 2.9 | 3.3 | 4.1 | 4.9 |

| 1.5 | 1.5 | 1.5 | 1.8 | 2.1 | 2.1 | 2.1 | 2.1 | 2.1 | |

| 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | |

| Number of modules | 1 | ||||||||

| weight (t) | 1.6 | 1.9 | 2 | 2.4 | 2.8 | 3.2 | 3.7 | 4.2 | 4.7 |

ZKL series self-cleaning air filters

Similar ProductsVIEW MORE >