After the air containing dust is inhaled by the aerodynamic equipment, it will cause the wear and tear of the equipment. The dust will scale on the surface of the fan blade, resulting in the decrease of the dynamic balance and imbalance accuracy of the rotor in the equipment, which greatly reduces the working life of the equipment. The harmful chemical components in the dust will make the equipment rust and corrosion. Therefore, aerodynamic equipment must be equipped with high precision air filter.

ZKL series self-cleaning air filter is improved based on the intake requirements of similar air compressors at home and abroad. At present, the product performance fully meets the intake requirements of industrial gas turbine blast furnace blast air compressor.

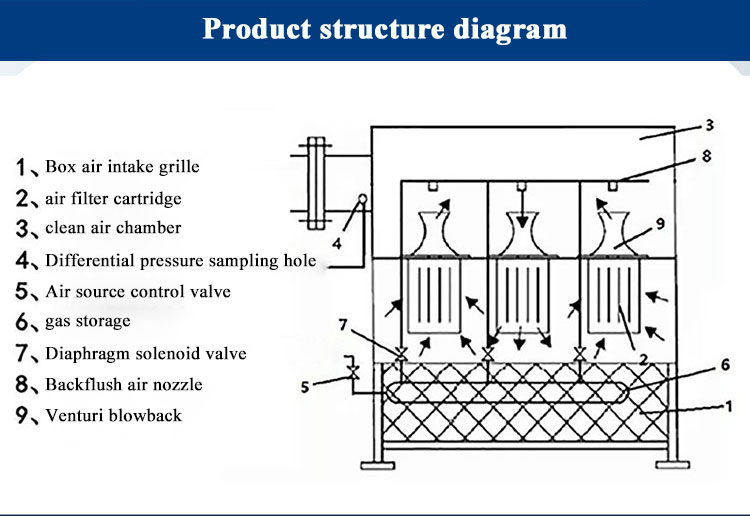

Dusty air is inhaled by air compressor and discharged by primary coarse filter box

1. Inhalation, through the high efficiency filter cylinder

2. Due to the combined effects of gravity inertia, diffusion and contact retention, dust is adsorbed on the high efficiency filter cylinder, and clean air passes through the sealing gasket

3. Enter the Wenner tube

4. Go to the net air chamber

5. Go to the air collection port

6. Then vent air from the clean air pipe

7. Inhaled by air compressor.

After the dusty air is filtered, the dust is adsorbed on the high efficiency filter cylinder, and the reverse blowing self-cleaning process is carried out by PLC in accordance with the set time sequence. When the resistance value exceeds 600pa, the back-blowing self-cleaning process is controlled by PLC pressing differential sequence (back-blowing time is 0.1-0.2 seconds). The other efficient filter canisters work as usual, and the dust is blown back to clean itself.

1. this product can be installed at the bottom of the dust collection box, air filter, water cleaning and dust removal methods according to user requirements, to solve the secondary pollution.

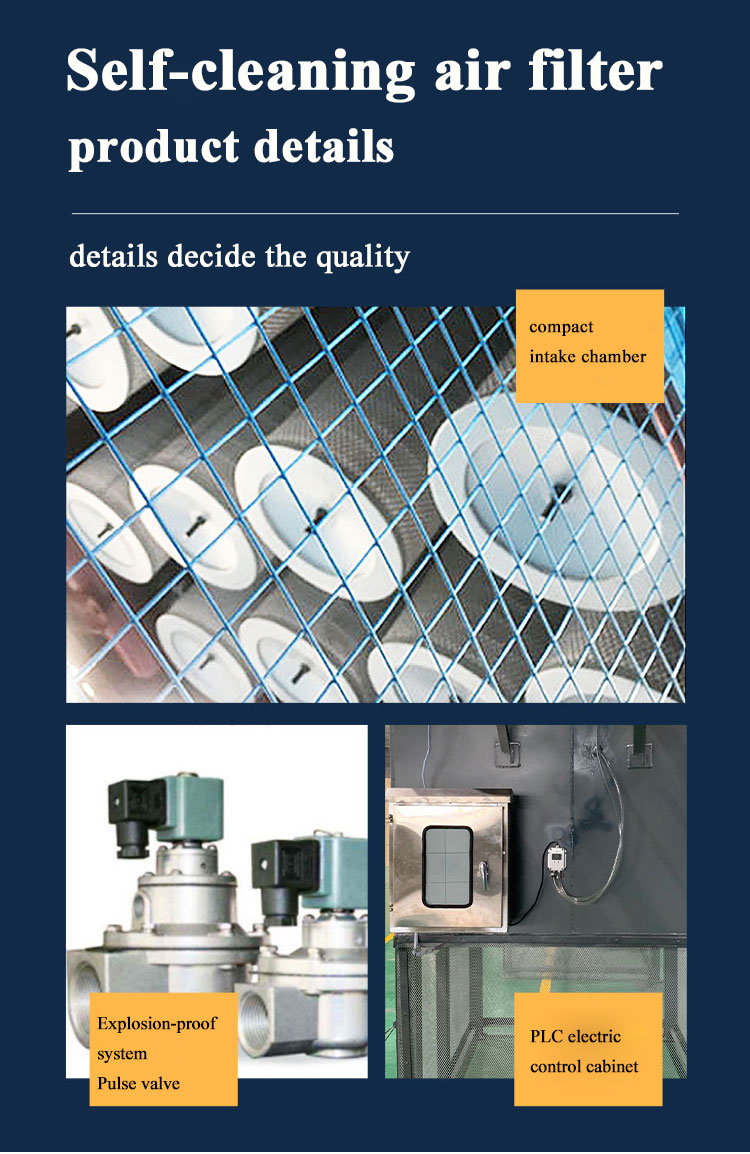

2. The device is controlled by an intelligent distributor and has three self-cleaning modes, namely (1) timing; (2) pressure difference; (3) Manual.

3. the equipment can realize the automatic cleaning of the air filter element, so that the normal operation of the equipment, does not affect the normal work of other filter elements.

4. It can work normally under 100% relative humidity.

5. the filter area is large, the flow rate is low, the resistance loss is small, and the LCD resistance loss is large.

6. Long service life of filter element. Under normal environmental conditions, the filter replacement cycle can be up to 2 years.

7. high degree of automation, the main parts are imported parts, can realize unmanned operation.

8. back blowing gas consumption is small, generally 0.1 ~ 0.3m3 / min(inhalation state); The pressure is 0.4 ~ 0.6Mpa.

9. the weight of the equipment is light, is the same capacity of the bag 1/3-1/2.

10. reasonable design, no bending design, high-rise block type combination, easy to install, fast.

11. this product has special requirements, the company can carry out non-standard design according to customer requirements, to meet customer needs.

1. For all kinds of air compressor stations in various industries, multiple sets of small-capacity compressors can be used together, and one set of large-capacity compressors can be used together.

2. Raw material air compressor for oxygen production station.

3. Blast furnace blower in steel mill.

4. Gas turbines of various capacities.

5. Diesel engines that need to run for a long time.

6, chemical fiber textile industry air conditioning supply system.

7. Centralized air conditioning system with high requirements for air dust content.

8. Solution pollution and prevention in chemical industry. (For pairing)

ATZK1000 self-cleaning air filter precision filtration

Similar ProductsVIEW MORE >