The brush type automatic self-cleaning filter produced by Aite Environmental protection is a kind of precision equipment that directly intercepts impurities in the water, removes suspended matter and particulate matter, reduces turbidity, purifies water quality, reduces system dirt, bacteria and algae, rust and so on

The brush type automatic self-cleaning filter produced by Aite Environmental protection is a kind of precision equipment that directly intercepts impurities in the water, removes suspended matter and particulate matter, reduces turbidity, purifies water quality, reduces system dirt, bacteria and algae, rust and so on, in order to purify water quality and protect other equipment of the system to work normally. The water enters the self-cleaning filter body from the water inlet. Because of the intelligent design, the system can automatically identify the degree of impurity deposition, and automatically discharge the sewage valve signal, so as to achieve a good filtering effect. Can be customized to various specifications.

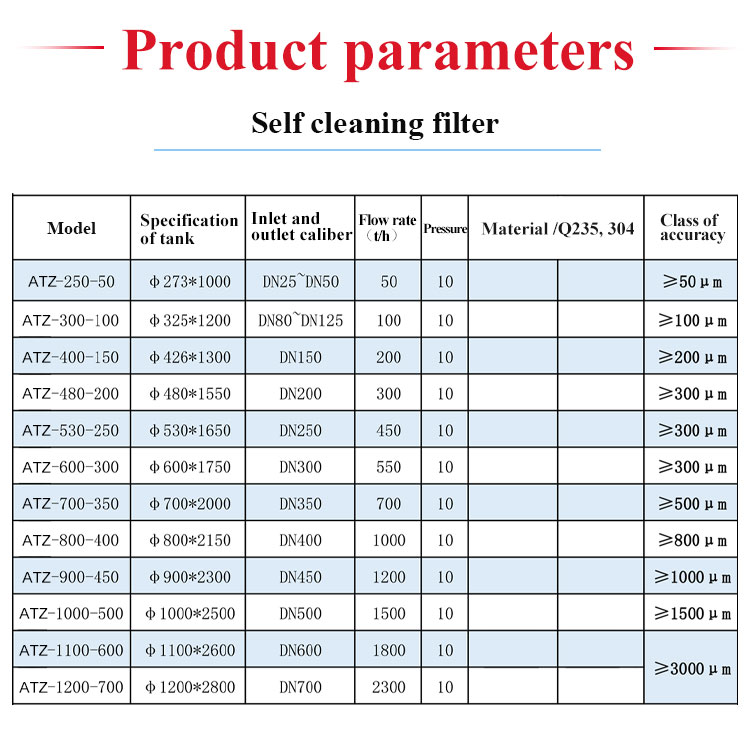

Single working flow: 4m3/h~4500m3/h.

Pressure grade: 1.0Mpa~2.5Mpa.

Operating water temperature range: ≤98C°.

Filtration accuracy :≥50 microns.

Filter cleaning head loss: < 0.01Mpa.

Import and export connection mode: flange.

Backwash time: 10~60 seconds.

Cleaning method: suction/brush.

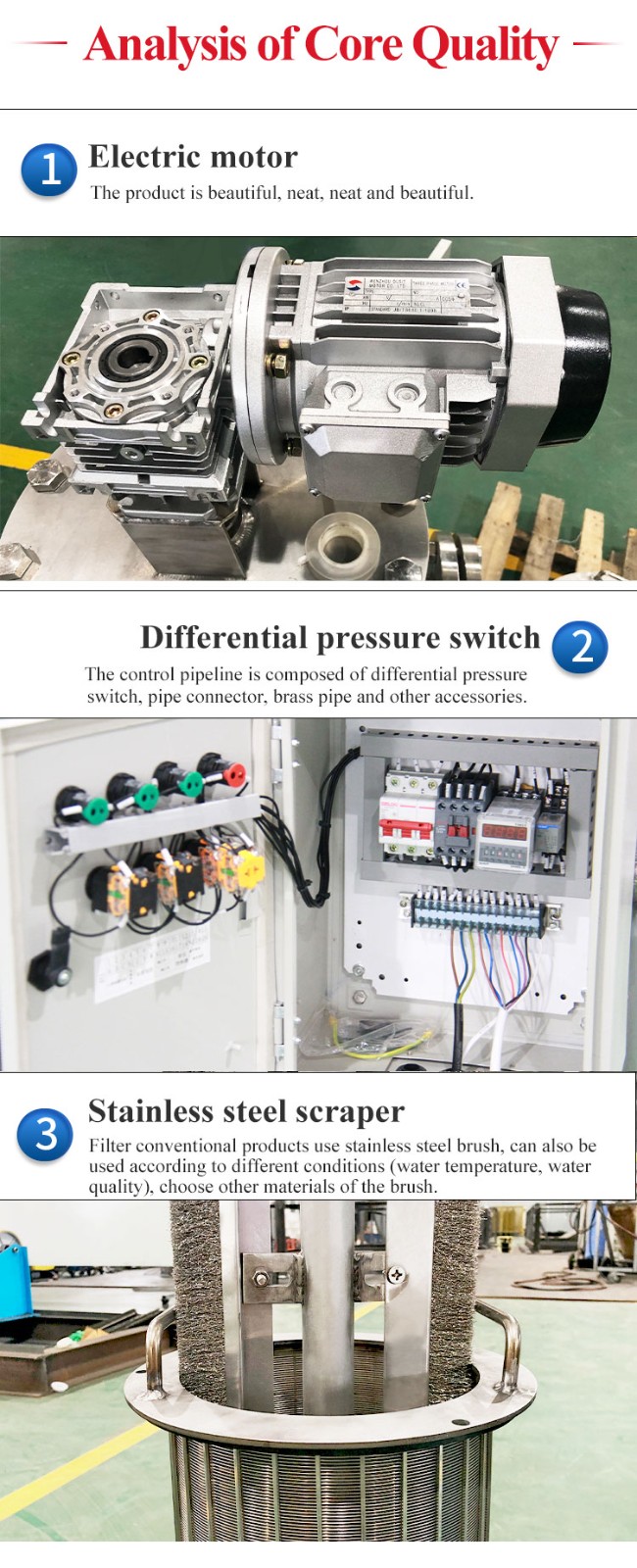

Control mode: pressure difference control/timing control.

Installation mode: vertical/horizontal

The water enters the filter from the water inlet, first filters out the impurities of larger particles through the coarse filter element assembly, and then reaches the fine filter screen. After filtering out the impurities of fine particles through the fine filter screen, the water is discharged from the outlet.

In the filtration process, the inner layer of impurities of the fine screen gradually accumulate, and a pressure difference is formed between the inner and outer sides of it. When this pressure difference reaches a preset value, the automatic cleaning process begins: the blowdown valve is opened, and the hydraulic motor chamber and hydraulic cylinder of the main assembly release pressure and expel water; Hydraulic motor room and suction pipe pressure drops significantly, because of the negative pressure, through the suction nozzle to absorb the fine filter screen inner wall of the dirt, by the hydraulic motor into the hydraulic motor room, discharged by the blowdown valve, forming a pollution absorption process. When the water flows through the hydraulic motor, it drives the sewage suction pipe to rotate, and the hydraulic cylinder piston drives the sewage suction pipe to make axial motion. The sewage suction device assembly is completely cleaned through the combination of axial motion and rotary motion. The whole cleaning process will last tens of seconds. The blowdown valve closes at the end of cleaning, and the increased water pressure returns the hydraulic cylinder piston to its initial position as the filter prepares for the next flush cycle. In the cleaning process, the filter normal filtration work uninterrupted.

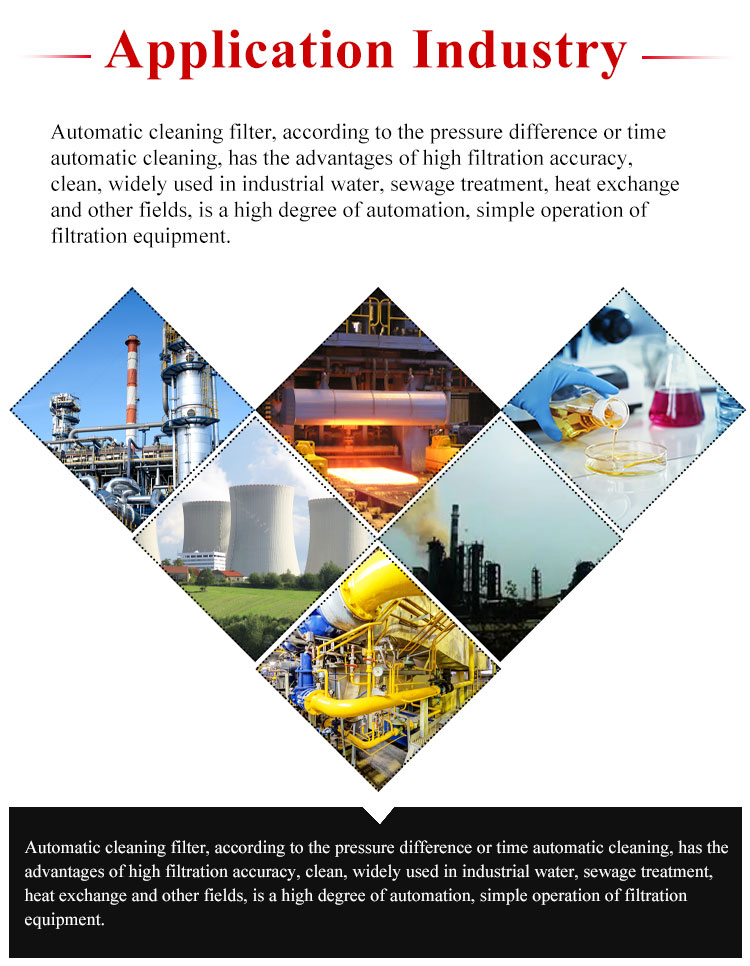

Steel: Used for raw material field, sinter pelletizing plant water treatment and filtration, blast furnace, rolling mill, continuous casting machine and other systems cooling water filtration, high pressure water phosphorus removal system impurity filtration

Automobile: coating production line, in the automobile, tractor, motorcycle, engine manufacturing water, treatment system has been widely used

Power plant: It is used for precision pretreatment of high purity water preparation of boiler in power plant, filtration of generator cooling water and sealing water. It can be used as side filtration treatment when the water consumption of 13-4 series is very large

Petrochemical industry: in the circulating water field to do side filtration treatment, can be single machine or multi-model parallel main processing, instead of filter material filtration, reduce filter material filtration load, can avoid a lot of washing water consumption, save costs

Agricultural garden and paper factory: in the sprinkler head, nozzle system, should reduce the equipment caused by impurities, wear, so need to choose high precision, high automatic filtration products machinery, food or other: automatic filtration of the system, used to prevent cooling water system blockage

Mine: Filter underground spray water to ensure the normal operation of the system. Water supply and sewage treatment: used in pretreatment system, improve the efficiency of system operation

It is widely used in drinking water treatment, building circulating water treatment, industrial circulating water treatment, sewage treatment, mining water treatment, golf course water treatment, construction, steel, petroleum, chemical, electronics, power generation, textile, papermaking, food, sugar, pharmaceutical, plastics, automobile industry and other fields.

Brush type automatic self-cleaning filter Key parameter

Similar ProductsVIEW MORE >