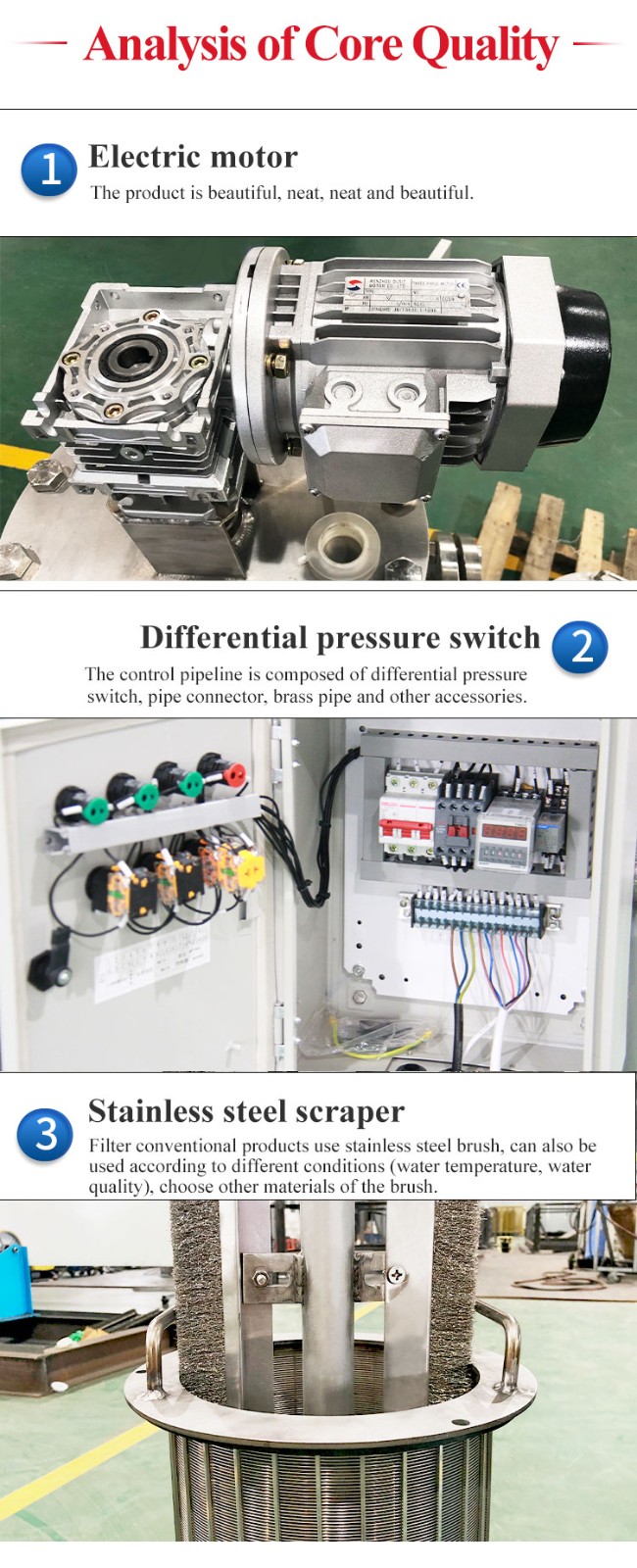

The internal structure of automatic brush filter is composed of stainless steel wire brush and stainless steel screen and transmission parts, by the transmission motor and electric valve to complete automatic cleaning and blowdown, operation mode for automatic operation (manual operation), with pressure difference and timing automatic blowdown dual functions.

The internal structure of automatic brush filter is composed of stainless steel wire brush and stainless steel screen and transmission parts, by the transmission motor and electric valve to complete automatic cleaning and blowdown, operation mode for automatic operation (manual operation), with pressure difference and timing automatic blowdown dual functions.

When the water flows through the filter, the mechanical impurities in the water are intercepted by the filter screen, when the impurities accumulated on the surface of the filter screen increase and the pressure difference reaches the set pressure difference, the pressure difference switch sends a signal, at the same time, the control box is issued instructions, the driving motor starts, the drain valve opens, the impurities deposited in the filter screen are rotated by the brush and discharged from the sewage outlet, The whole process of scrubbing blowdown does not require personnel operation or shutdown. At the same time, the equipment is also equipped with periodic cleaning blowdown and manual cleaning blowdown functions to ensure the highest reliability of effluent under any circumstances.

Automatic filter to overcome the traditional filtration products of small amount of pollution, easy to be blocked by dirt, filter part needs to be removed cleaning and can not monitor the filter state and many other shortcomings, with the raw water filtration and automatic filter element automatic cleaning sewage function, and cleaning sewage system uninterrupted water supply, can monitor the filter working state, a high degree of automation.

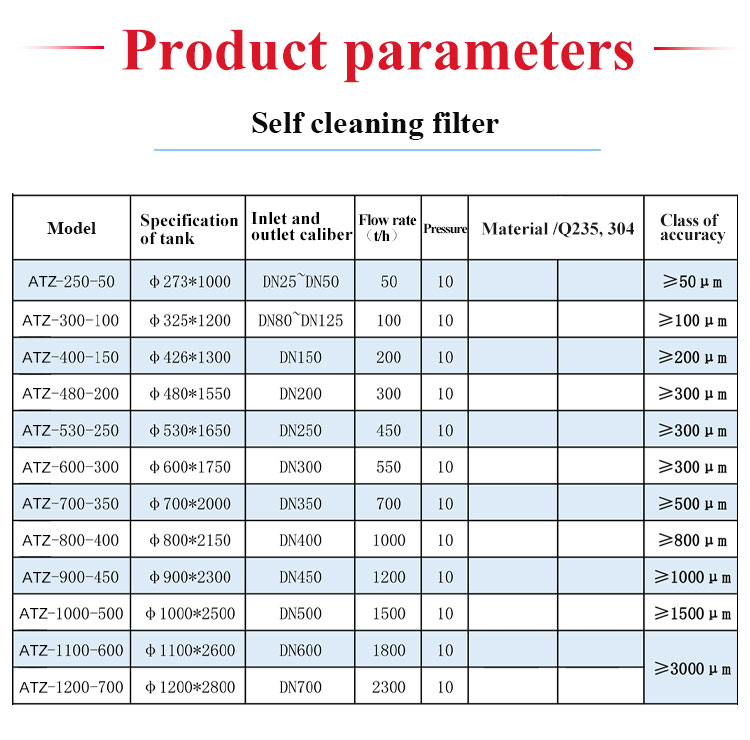

1) The default filtration accuracy is 100 microns, and optional from 50 to 3000 microns, large filtration area, high contaminant capacity, users can customize according to the actual working conditions.

2) The cleaning method is simple, and the cleaning cycle is monitored electronically, which can realize automatic cleaning and blowdown. All parameters in the automatic self-cleaning filter control system can be adjusted.

3) Equipped with motor overload protection, can effectively protect the motor.

4) It has the characteristics of uninterrupted water supply and no bypass when cleaning sewage, and the cleaning time is short, and the sewage consumption is less, not more than 1% of the total flow.

5) Strong maintainability, easy to install and disassemble.

6) The connection mode with the user pipeline is flange connection, and the flange adopts national standard flange with strong universality.

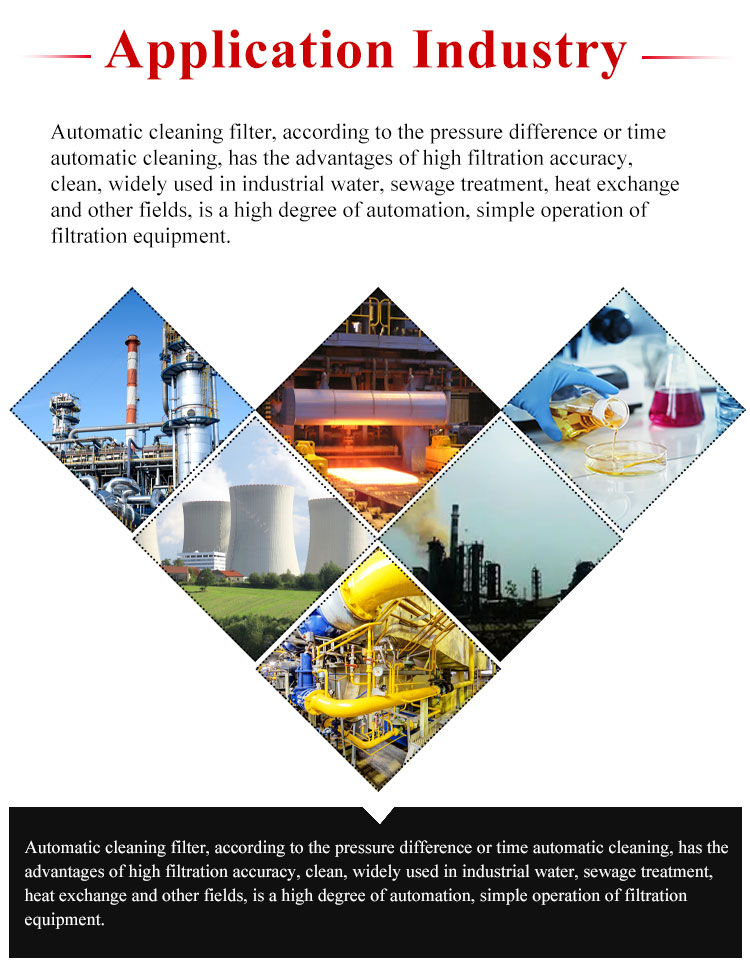

Metallurgy: continuous casting water, high pressure phosphorus removal water, clean ring water, turbidity ring water filtration, cooling water filter, filter, nozzle protection, etc

Power: turbine cooling water filtration, gray water recovery filtration, dust removal nozzle protection, cooling tower water filter and by-filter, etc

Raw water: lake water, river water, reservoir water, well water, rainwater, groundwater extraction sand, algae, organic matter filtration

Agriculture: spray irrigation, drip irrigation water treatment

Others: construction, steel, petroleum, chemical, electronics, power generation, textile, paper, food, sugar, pharmaceutical, plastics, automobile industry, etc

It is widely used in drinking water treatment, building circulating water treatment, industrial circulating water treatment, sewage treatment, mining water treatment, golf course water treatment and other fields.

The equipment has been debugged before leaving the factory, and users can run it directly when using it. When the operating parameters of the equipment cannot meet the requirements of the user, the user can adjust the parameters according to the actual working conditions, and choose the manual control or automatic control mode to work accordingly.

When running, the following steps should be followed:

Check whether the filter is in normal working condition:

Check whether the connection of the filter is firm.

Check the electric cabinet part of the filter should be dry.

When the power supply is switched on, the green power indicator lights up, indicating that the electronic control part of the filter is in normal working state, and the equipment can be put into trial operation.

Note: Keep your hands dry when you plug in the power supply. At the same time, keep the electric control unit dry during the working process of the filter. No water can enter the electric control unit.

Fully automatic self-cleaning filter equipment

Similar ProductsVIEW MORE >