Hand brush type mechanical filter is installed on the pipeline to filter rust, sand and other solid impurities in the fluid, protect the equipment on the pipeline from wear and blockage, so that the machine equipment: compressors, water pumps, valves, instruments and so on can work and operate normally, to achieve a stable process, ensure the role of production.

Hand brush type mechanical filter is installed on the pipeline to filter rust, sand and other solid impurities in the fluid, protect the equipment on the pipeline from wear and blockage, so that the machine equipment: compressors, water pumps, valves, instruments and so on can work and operate normally, to achieve a stable process, ensure the role of production.

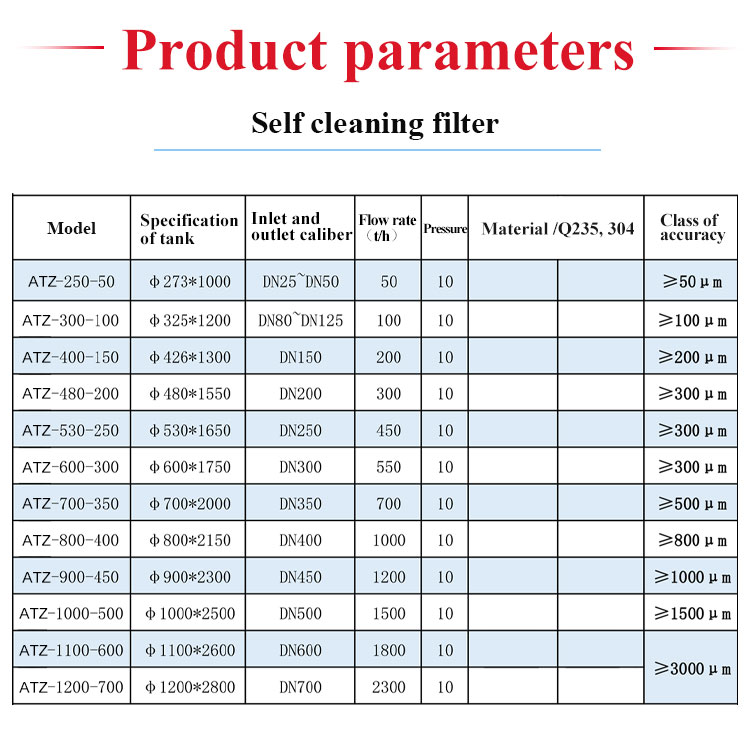

Working pressure: ≤1.0Mpa(If you need higher working pressure, please specify when ordering)

Pressure loss force: ≤0.015Mpa

Filtration accuracy: 0.8mm (0.2~3.5mm accuracy range can be manufactured)

High operating temperature: ≤100°C

Shell material : carbon steel

Filter element : 304 stainless steel

Bolts and nuts : 304 316L

Filtration: accuracy of 10~500 mesh

The ambient temperature: -30℃ to 450℃

Nominal pressure: 0-10.0mpa

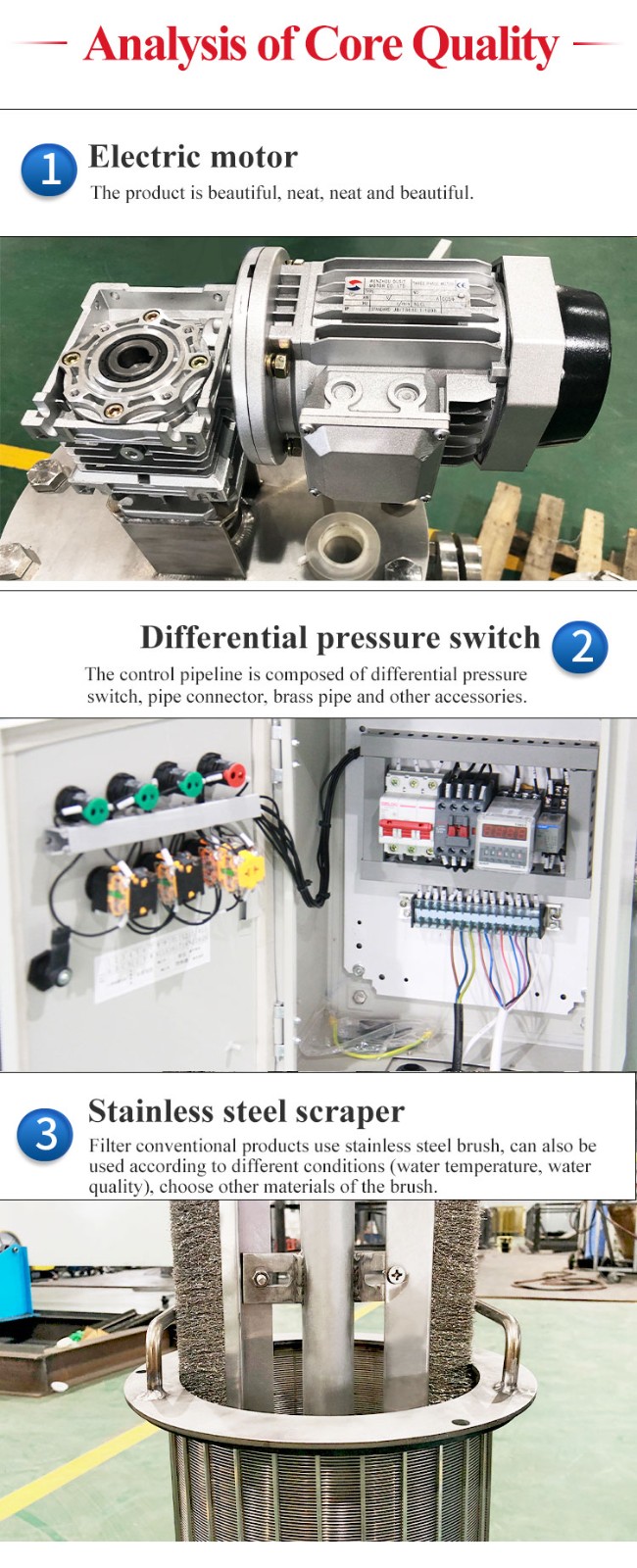

1. The cleaning method of the equipment is brush forced cleaning, especially suitable for poor water quality, bad environment places; The cleaning effect of viscous impurities is better than other ways.

2. The equipment is equipped with a pressure gauge at the inlet and outlet. In order to facilitate the user to judge whether to clean the filter element by the pressure difference of the inlet and outlet (when the pressure difference of the inlet and outlet reaches about 0.2Mpa, or when the pressure difference is 3-4 times larger than that of the new installation, it indicates that the inner wall of the filter element has been hung with dirt or impurities. It is recommended to clean the filter element at this time. When the pressure difference is less than 0.1MPa, the cleaning can be stopped)

3. The ordinary filter needs to shut down the system to discharge, and the automatic discharge filter does not need to shut down, truly realizing online discharge.

4. The ordinary filter element can be cleaned only after manual disassembly. The filter sets filtering, forced cleaning and sewage discharge functions in one, and can be cleaned without manual disassembly.

5. When it is necessary to drain, open the drain valve first and shake the handle at the same time. At this time, the built-in brush of the filter element constantly brushes the dirt and impurities on the filter component.

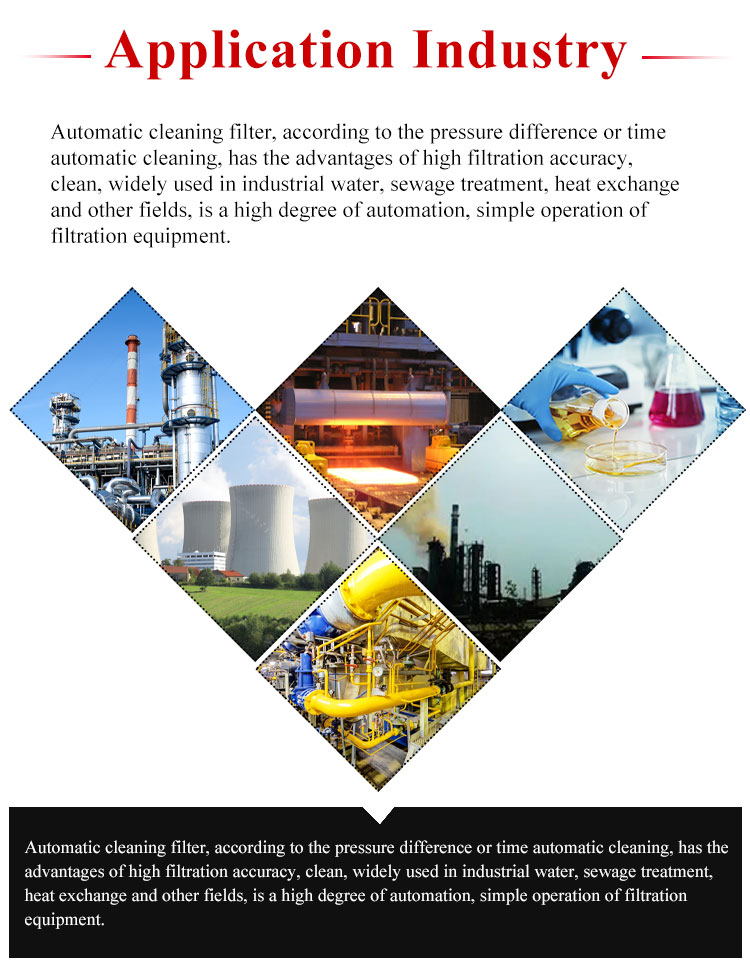

Steel: Used for raw material field, sinter pelletizing plant water treatment and filtration, blast furnace, rolling mill, continuous casting machine and other systems cooling water filtration, high pressure water phosphorus removal system impurity filtration

Automobile: coating production line, in the automobile, tractor, motorcycle, engine manufacturing water, treatment system has been widely used

Power plant: It is used for precision pretreatment of high purity water preparation of power plant boiler, filtration of generator cooling water and sealing water. It can be used as side filtration treatment when the water consumption of system 13-4 is very large

Chemical industry: in the circulating water field to do side filtration treatment, can be single machine or multi-model parallel main processing, instead of filter material filtration, reduce filter material filtration load, can avoid a lot of washing water consumption, save costs

Agricultural gardens and paper mills: In the system with sprinkler heads and nozzles, equipment blockage and wear caused by impurities should be reduced, so it is necessary to choose high-precision and high-automation filtration product machinery.

Mine: Filter underground spray water to ensure the normal operation of the system.

Others: Automatic and accurate filtration of the system to prevent the blockage of the cooling water system.

Hand brush mechanical filter

Similar ProductsVIEW MORE >