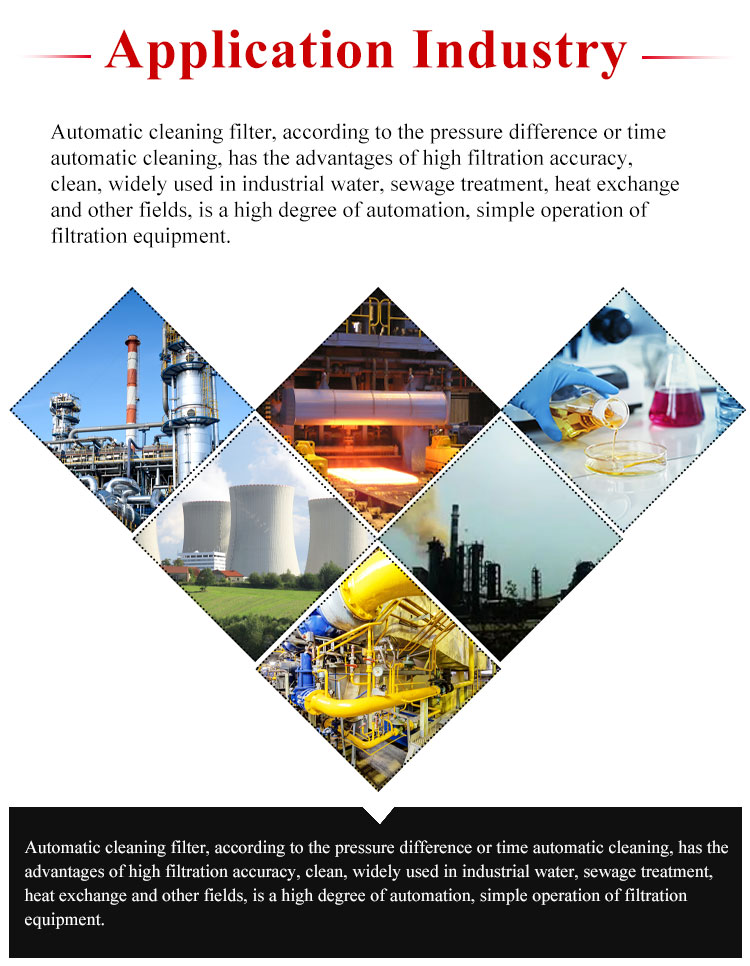

Self-cleaning filter is a kind of precision equipment that uses the filter screen to directly intercept the impurities in the water, remove suspended matter and particulate matter, reduce turbidity, purify water quality, reduce system dirt, bacteria and algae, rust and so on, in order to purify water and protect the normal work of other equipment in the system. The water enters the self-cleaning filter body from the water inlet, due to the intelligent (PLC, PAC) design, The system can automatically identify the degree of impurity deposition, and automatically discharge the sewage valve.

Self-cleaning filter is a kind of precision equipment that uses the filter screen to directly intercept the impurities in the water, remove suspended matter and particulate matter, reduce turbidity, purify water quality, reduce system dirt, bacteria and algae, rust and so on, in order to purify water and protect the normal work of other equipment in the system. The water enters the self-cleaning filter body from the water inlet, due to the intelligent (PLC, PAC) design, The system can automatically identify the degree of impurity deposition, and automatically discharge the sewage valve.

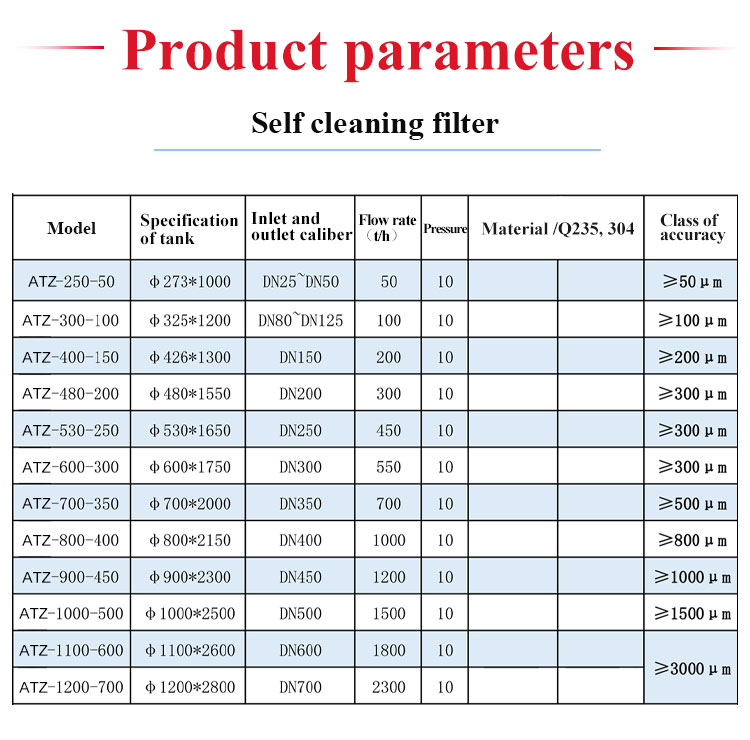

Water treatment capacity of a single unit: 10-200m /h.

Minimum working pressure: 2bar (30psi).

Maximum working pressure: 1.0MPa, 1.6MPa.

Filter cleaning pressure loss: 0.01MPa.

Maximum operating water temperature: 65℃ (149°F).

Filtration accuracy range: 25-400μm (micron).

Water requirement for self-cleaning: 2-4" over the swimmer, -8 L; 4S-8" filter, -25 L.

Self-cleaning time: 5 seconds.

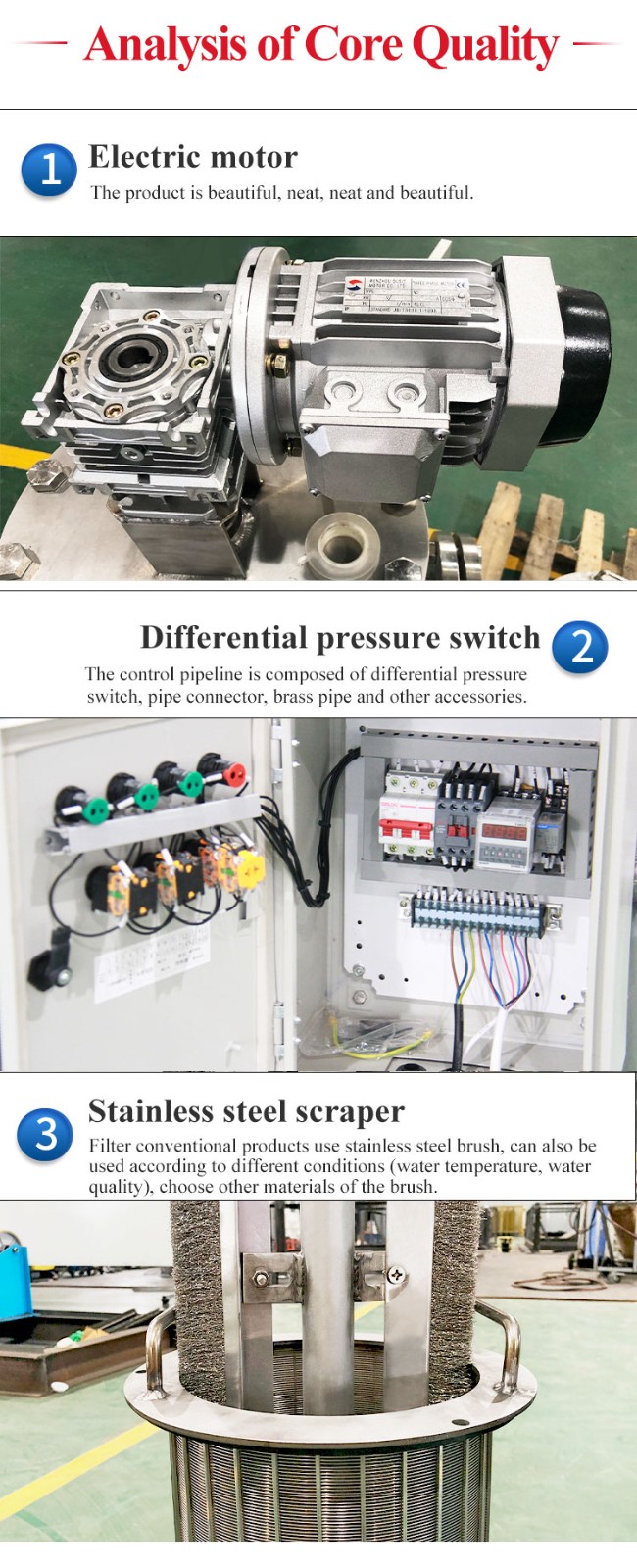

Self-cleaning control mode: differential pressure, time and manual.

Electric control mode: DC 12V; Ac 24V.

Filter self-cleaning is completely dependent on the water pressure in the system line, without external power.

The water enters the filter from the water inlet, first filters out the impurities of larger particles through the coarse filter element assembly, and then reaches the fine filter screen. After filtering out the impurities of fine particles through the fine filter screen, the water is discharged from the outlet.

In the filtration process, the inner layer of the fine filter impurities gradually accumulate, and a pressure difference is formed on both sides of it. When this pressure difference reaches a preset value, the automatic cleaning process begins: the blowdown valve is opened, and the hydraulic motor chamber and hydraulic cylinder of the main assembly release pressure and drain water; Hydraulic motor room and suction pipe pressure drops significantly, because of the negative pressure, through the suction nozzle to absorb the fine filter wall of the dirt, by the hydraulic motor into the hydraulic motor room, discharged by the sewage valve, forming a pollution suction process. When the water flows through the hydraulic motor, it drives the sewage suction pipe to rotate, and the hydraulic cylinder piston drives the sewage suction pipe to make axial movement. The sewage suction device assembly completely cleans the inner surface of the whole filter screen through the combination of axial movement and rotary movement. The whole cleaning process will last tens of seconds. The drain valve closes at the end of cleaning and the increased water pressure causes the hydraulic cylinder piston to return to its initial position and the filter to prepare for the next flush cycle. In the cleaning process, the filter normal filtering work is uninterrupted.

The principle of automatic backwashing: As mentioned earlier, backwashing is achieved by hydraulic valve opening and hydraulic cylinder piston action, and these are controlled by the backwashing controller. The backwash controller can accurately control the hydraulic valve and cylinder according to the pressure difference transmitted from the filter inlet and outlet. The power of the controller comes from the pressure of the pipeline itself.

Self-cleaning filter characteristics: uninterrupted water supply when backwashing, the whole backwashing is realized by the way of cleaning each point of the filter screen through the suction nozzle. When backwashing, there is only a small local pressure change between the nozzle and the fine filter, and the action of the collector and the hydraulic cylinder does not affect the normal water supply. At the same time, the amount of water consumed in backwashing is very small, with the flow rate of 300m3/h. For example, the backwashing flow of the filter is 35-40m3 /h, the backwashing time is 7-15 seconds, and the backwashing water is 80-160L .

1. The self-cleaning filter can only be used according to the rated voltage/frequency marked on the nameplate.

2. Maintain the filter every once in a while. Before cleaning and maintenance, be sure to disconnect the power supply of the self-cleaning filter.

3. Please make sure that the wire plug is not wet during cleaning or it must be wiped dry before reconnecting the power supply.

4. Do not unplug the power cable with wet hands.

5. Self-cleaning filter is only used in indoor aquariums.

6. Do not use the filter if it is damaged, especially the power cable.

7. Please ensure that the self-cleaning filter is working at the correct water level. The filter cannot be used without water.

8. Please do not disassemble or maintain it privately to avoid danger or damage to the body. The maintenance should be carried out by professionals

Precision conversion editor

Automatic mesh self-cleaning filter

Similar ProductsVIEW MORE >