The multi-core self-cleaning filter is integrated with multi-slot filter elements. When the filter elements are blocked, the backwash jib will backwash the filter elements one by one

Themulti-core self-cleaning filter is integrated with multi-slot filter elements. When the filter elements are blocked, the backwash jib will backwash the filter elements one by one. The filter has the outstanding advantage of being different from the ordinary mesh self-cleaning filter. It adopts the rugged wedge-shaped fillet filter element, the surface gap width is uniform, the filtering accuracy range is 50-2000 microns, the inlet and outlet size is 2"-24", the single machine has the largest filtering area, the low surface flow rate can be fine filtering, and the single machine flow rate can reach 8000m3/h. ji high reliability, can be qualified for poor water quality, such as oily sludge impurities, soft viscous impurities, high impurity content, a small amount of hair and fiber impurities.

Multi-core self-cleaning filter can filter all kinds of water and low viscosity liquid (such as machining coolant) in solid particle impurities, to meet the system operation and the next process of liquid cleanliness requirements, can also be used to protect downstream key equipment from particle blockage, wear or scaling, improve the operation efficiency and life of key equipment. The machine can fully automatic on-line continuous filtration, reduce the shutdown cost, maintenance cost and labor cost, is the solution of water and water-based liquid filtration.

■ Automatic continuous on-line filtration, uninterrupted flow during backwashing, reducing parking and maintenance costs;

■ Large filtration area, low surface flow rate, low pressure energy loss, fine filtration, low recoil frequency, save recoil water;

■ Adopt wedge wire filter element, filter crevice fine, backwash, strength structure, service life of more than 10 years;

■ Pulse recoil, align the filter element and then open the drain valve recoil, backwashing strength is high, good effect, short time, save water;

■ Both ends of the filter element are fed water at the same time to increase the flux of the filter element. The free flow of water can delay the surface blockage and avoid the blockage at one end of the filter element;

■ Compact design, single machine can realize large flow filtering, significantly saving installation space and construction cost;

■ Highly integrated, without a large number of automatic valves, connectors, seals, high reliability, low operation and maintenance cost;

■ The automatic control system has high reliability, intuitive interface and easy operation. It can control the filter to run efficiently according to the actual working conditions.

■ Applicable industries: water treatment, steel, paper, mining, petrochemical, mechanical processing, municipal, agricultural irrigation, etc.

■ Applicable liquid types: groundwater, sea water, lake water, reservoir water, pond water, circulating cooling water, frozen water, high and low pressure spray water, water needle water, heat exchange water, sealing water, bearing cooling water, oil well injection, process circulating water, machining coolant, cleaning agent, cleaning water, etc.

■ Filter form: wedge - shaped wire gap

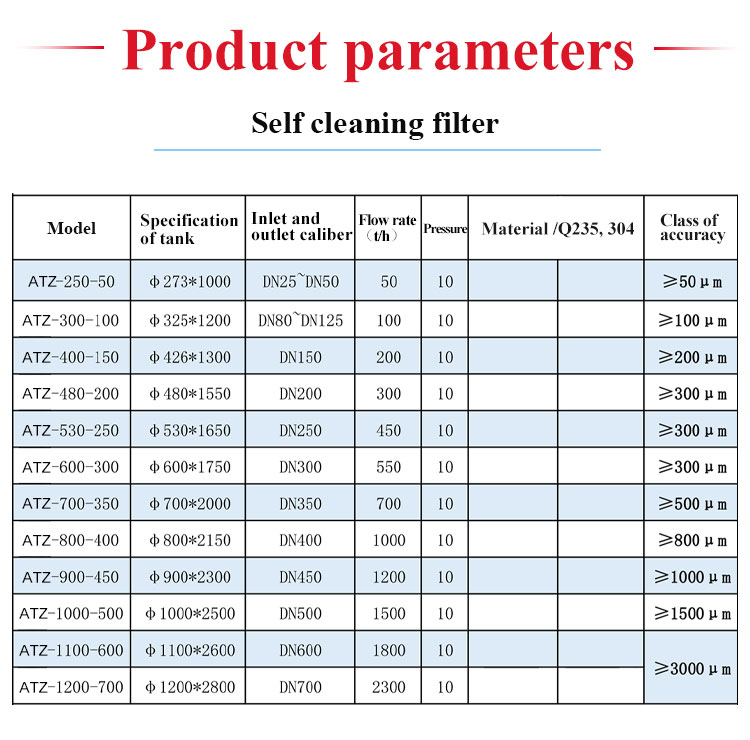

■ Single machine flow (m? /h) : 17-8000

■ Optional accuracy (μm) : 50-5000

■Shell material: 304,316L,CS

■ Applicable viscosity (cp) : 1-40

■ Applicable temperature (°C) : 0-95

■ Working pressure (MPa) : 0.6, 1.0,1.6,2.5

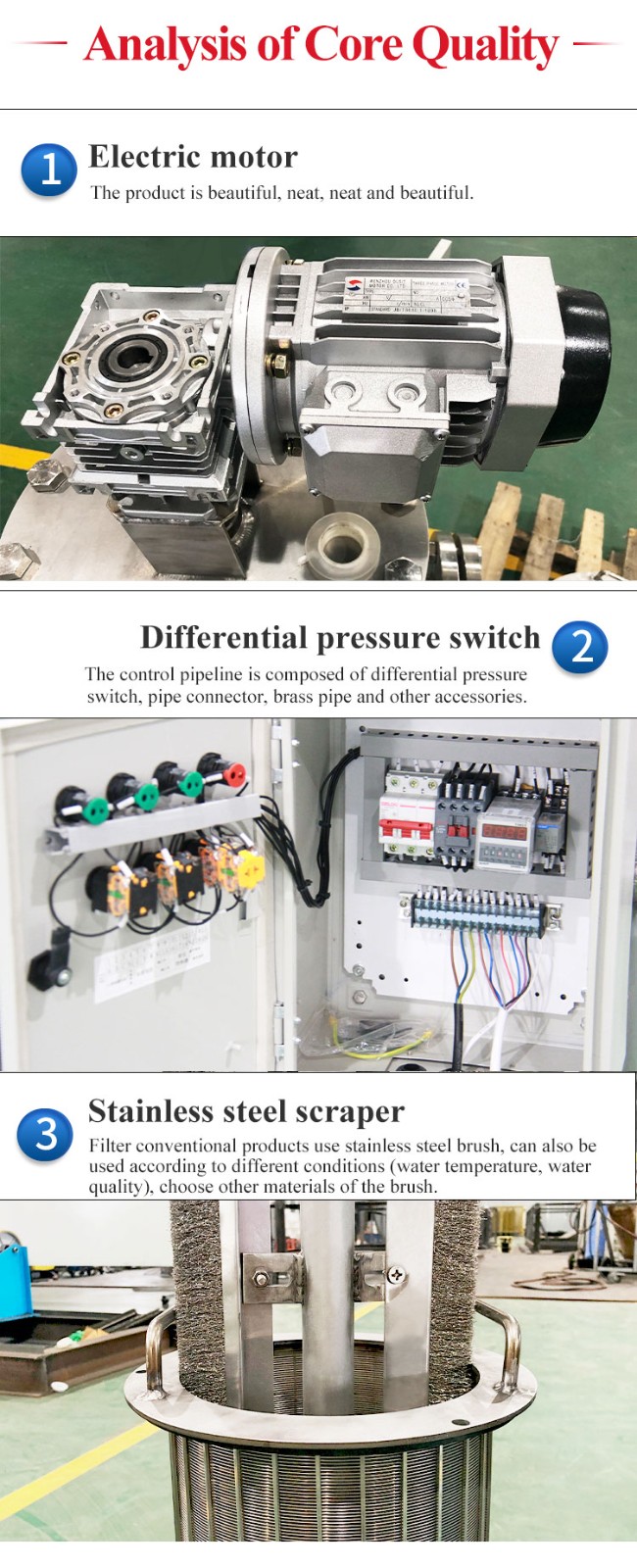

■ Cleaning start mode: time start, differential pressure start

Multi-core self-cleaning filter

Similar ProductsVIEW MORE >