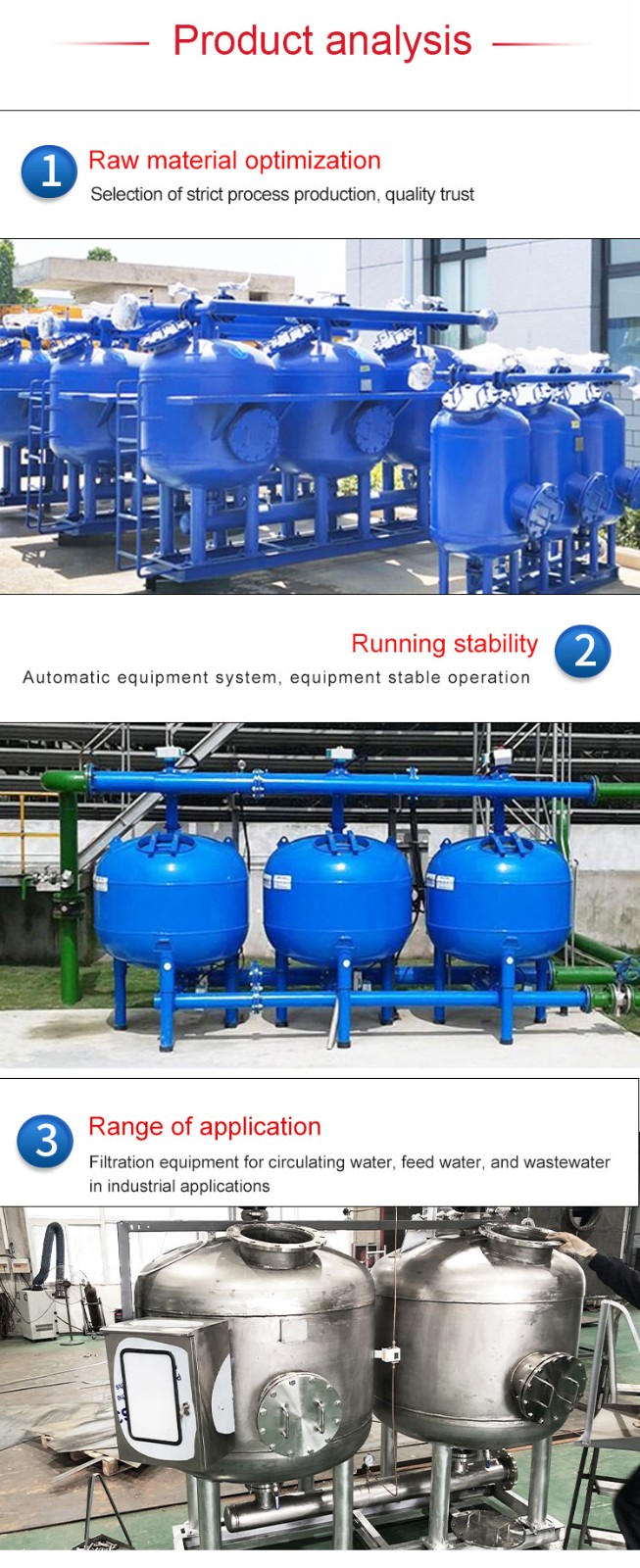

Side filter, also known as shallow sand filter, is mainly used in the industrial field of circulating water, water supply, and wastewater filtration. HGBMF's medium filtration system utilizes deep media to effectively remove particulate matter and reduce turbidity. If loaded with a specific filter material, such as activated carbon, zeolite, can also adsorb the corresponding organic matter, ions and so on. The fluidization device in the system (bottom drainage device) can fluidize the filter medium, remove the pollutants trapped in the medium, and discharge them, and get a thorough cleaning.

Side filter, also known asshallow sand filter, is mainly used in the industrial field of circulating water, water supply, and wastewater filtration. HGBMF's medium filtration system utilizes deep media to effectively remove particulate matter and reduce turbidity. If loaded with a specific filter material, such as activated carbon, zeolite, can also adsorb the corresponding organic matter, ions and so on. The fluidization device in the system (bottom drainage device) can fluidize the filter medium, remove the pollutants trapped in the medium, and discharge them, and get a thorough cleaning.

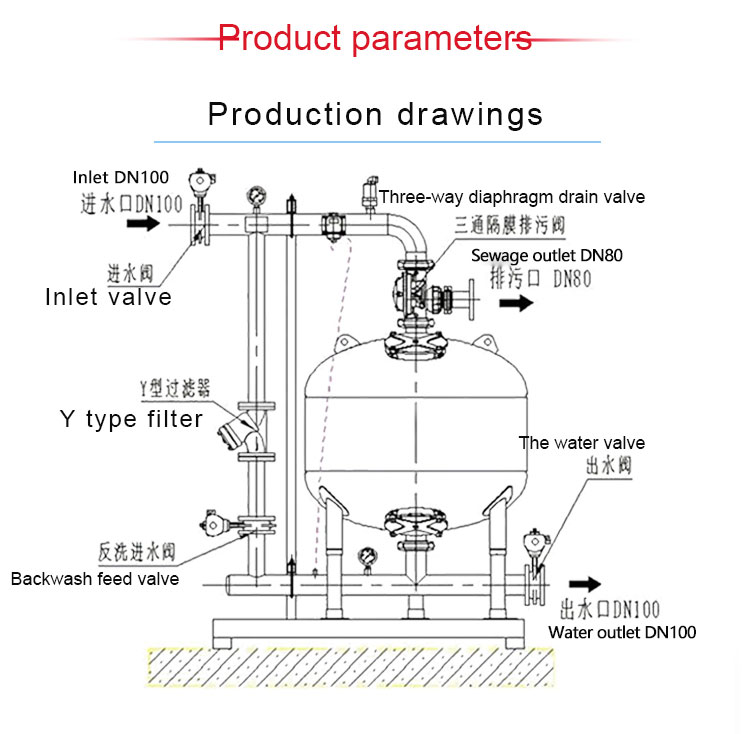

When the system is in the filtering state, the pressurized water flows into the water distribution system from the filter tank inlet and uniformly reaches the filter material layer. When the water filters the material layer, the suspended matter is intercepted by the filter material. At the bottom of the filter is a water collector with a precise gap, and the filtered water is uniformly collected and drained out of the filter. The precise gap on the water collector can effectively prevent the loss of filter material. Mechanical battlements (pneumatic or electric) control the flow of water.

When the system is in the automatic backwash state, the backwash cycle is controlled by increasing pressure differences. With the continuous accumulation of impurities in the filter material layer, the pressure loss continues to increase, when the pressure difference increases to a certain set value, the system will automatically switch to the backwash state. Pressurized water enters the filter material layer through the fluidization device (i.e. the water collection device), scour it, and make the trapped pollutants fall off and discharge out of the filtration system. After the backwash lasts for at least 2 minutes, the valve automatically switches the system to the filtered state.

Filter container: epoxy carbon steel; The ASME; 50psig(0.345Mpa), with manual and automatic air outlet, inlet and outlet 100 and 150psig (0.69 and 1.03Mpa), ASME code mark;

Water distribution device: 80PVC upper drainage device, lower drainage device;

Filter media: Unigran 85 (10 micron) Unigran 55(5 micron) and Unigran20(0.45 micron);

Backwash start:

Automatic: 24 hour /7 day clock, differential pressure switch and manual button;

Manual: control stick BMS remote control; Backwash water source: water tower/system water or municipal water/external water source automatically select dual water source;

Backwash time: 3 minutes (adjustable clock);

External piping: 80 PVC epoxy carbon steel or 304 stainless steel;

Pump/motor: independent water pump;

Control valve: Battlement valve, body is epoxy cast iron, valve plate is cast iron nylon 11, EDPM sealed hydraulic valve;

Valve action: pneumatic film actuator with failure protection device electric actuator;

Electric control device: power switch, overload thermal protector, transformer with fuse protection other according to requirements;

Power supply: standard voltage, 50 or 60Hz (single-phase or three-phase);

Foundation/rail: epoxy carbon steel - beam foundation

Coal swirls through the colander

Similar ProductsVIEW MORE >