Side filter, also known as shallow sand filter, is mainly used in the industrial field of circulating water, water supply, and wastewater filtration. HGBMF's medium filtration system utilizes deep media to effectively remove particulate matter and reduce turbidity. If loaded with a specific filter material, such as activated carbon, zeolite, can also adsorb the corresponding organic matter, ions and so on. The fluidization device in the system (bottom drainage device) can fluidize the filter medium, remove the pollutants trapped in the medium, and discharge them, and get a thorough cleaning.

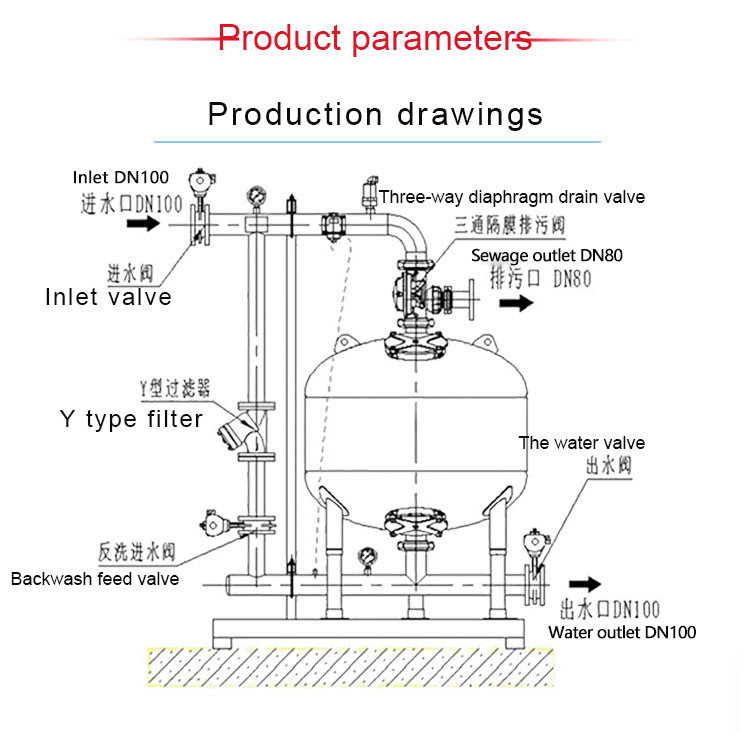

Washing filtration state: when the system is in the filtering state, the unfiltered water is evenly distributed through the unique water distributor developed by itself, and the water is laminar flow through the filler layer in the filter (refined homogeneous quartz sand/garnet). When water flows through the packing layer, impurities are trapped in the packing layer. The bottom of the filter has a plurality of evenly distributed water collector, the filtered water will be evenly collected and drawn out, advection filtration, can make the filter filter at high flow rate, still can achieve a better filtering effect.

Backwash state: with the continuous accumulation of impurities in the packing layer, the internal indenter loss will increase. When the loss of inlet and outlet water pressure heads reaches the set value, the system will automatically activate the constant pressure device to convert it to the backwashing state. When the backwashing is over, the hydraulic valve changes the water supply direction to realize backwashing one by one, which is more convenient to clean the accumulated impurities.

When the system is in the state of backwashing, filtration still continues. The standard unit sand cylinder to be backwashed is not filtered, and other standard unit sand cylinders in the system are still filtered. The filtered clean water is used to backwash the standard unit sand tank, and the rest is sent to the user. Backwash sewage is discharged through the backwash outlet of the hydraulic valve. In the high-speed sand cylinder automatic filtration system, the special water collector design can make the packing between the packing rub each other, maximize the backwash efficiency, reduce the required backwash water (clean water), at the same time, there is no running material phenomenon in the backwash. The backwashing time of one standard unit sand cylinder is 2 minutes. After the backwashing is finished, the loss of the pressure head inside the sand cylinder of the standard unit is reduced to a reasonable range, the constant pressure device gives a recovery signal, the hydraulic valve is restored to the filtering state, and the next standard unit sand cylinder is ready to enter the backwashing state.

When the system is in the filtering state, the pressurized water flows into the water distribution system from the filter tank inlet and uniformly reaches the filter material layer. When the water filters the material layer, the suspended matter is intercepted by the filter material. At the bottom of the filter is a water collector with a precise gap, and the filtered water is uniformly collected and drained out of the filter. The precise gap on the water collector can effectively prevent the loss of filter material. Mechanical battlements (pneumatic or electric) control the flow of water.

When the system is in the automatic backwash state, the backwash cycle is controlled by increasing pressure differences. With the continuous accumulation of impurities in the filter material layer, the pressure loss continues to increase, when the pressure difference increases to a certain set value, the system will automatically switch to the backwash state. Pressurized water enters the filter material layer through the fluidization device (i.e. the water collection device), scour it, and make the trapped pollutants fall off and discharge out of the filtration system. After the backwash lasts for at least 2 minutes, the valve automatically switches the system to the filtered state.

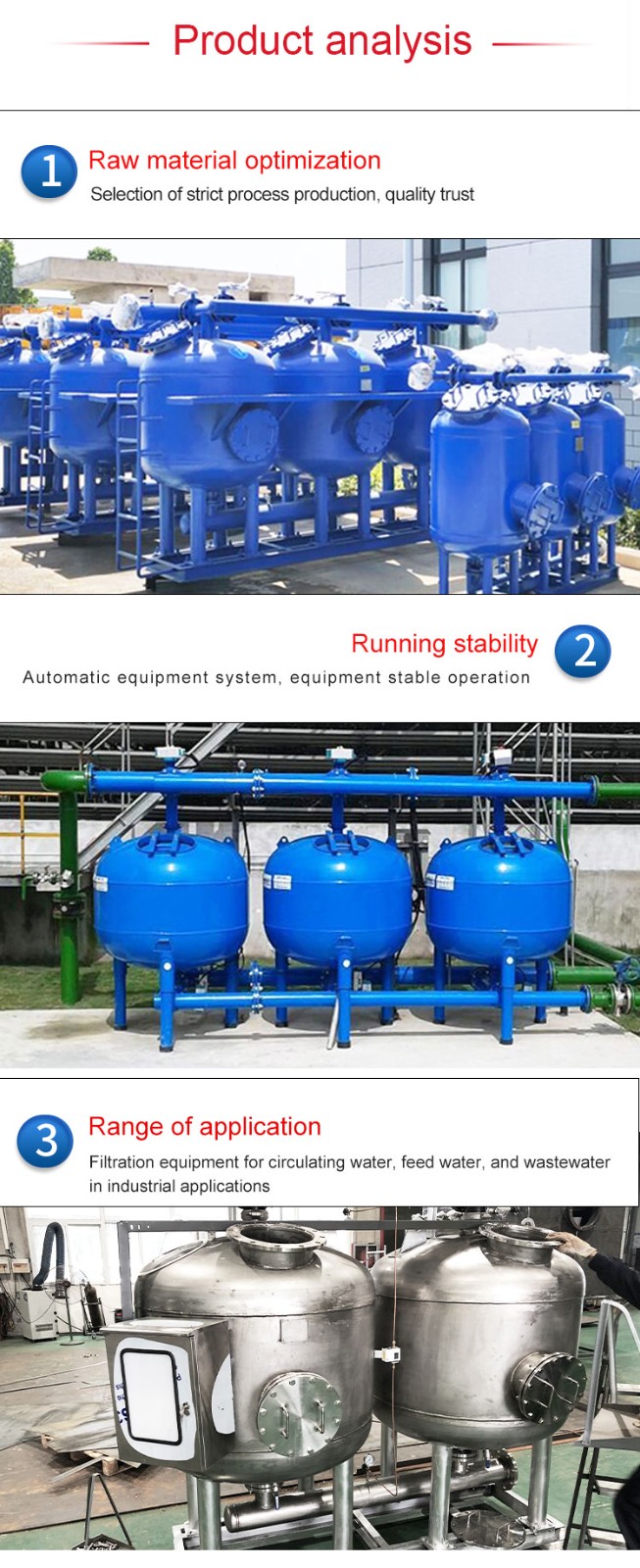

1, industrial water filtration - there are certain system requirements for water quality. Such as: steel oxygen gun water, boiler, heat exchanger water filtration, can filter out the impurities in the water, to avoid the blockage of the pipeline and nozzle.

2, industrial circulating water filtration system.

3, raw water treatment - surface river water, lake water, sea water, reservoir water, well water and urban tap water as a source of urban small quality water supply filtration, remove the sand in the water, suspended matter, algae, organic matter and so on.

4, agricultural irrigation - especially suitable for high flow, good impurity content of water sources, such as irrigation irrigation, parks and golf courses on the lawn irrigation.

5, food processing industrial water, paper industry, power plant industrial circulating water treatment, industrial and medical treatment of purified water. Industrial production water recycling, industrial waste water treatment.

6. Aquaculture, swimming and water parks.

Agricultural sand filter

Similar ProductsVIEW MORE >