The use of degassing elements can greatly improve the efficiency of dehydration and degassing.

The two-stage vacuum oil purifier adopts degassing elements, which can greatly improve the dehydration and degassing efficiency. It adopts advanced photoelectric control defoaming device. The oil level control adopts mechanical and electronic control type and overpressure alarm device, which can realize automatic operation. The oil inlet and outlet have the interchange function, and the oil inlet and outlet can be interchanged freely through the valve control during operation, and there is no need to disassemble the oil change pipe.

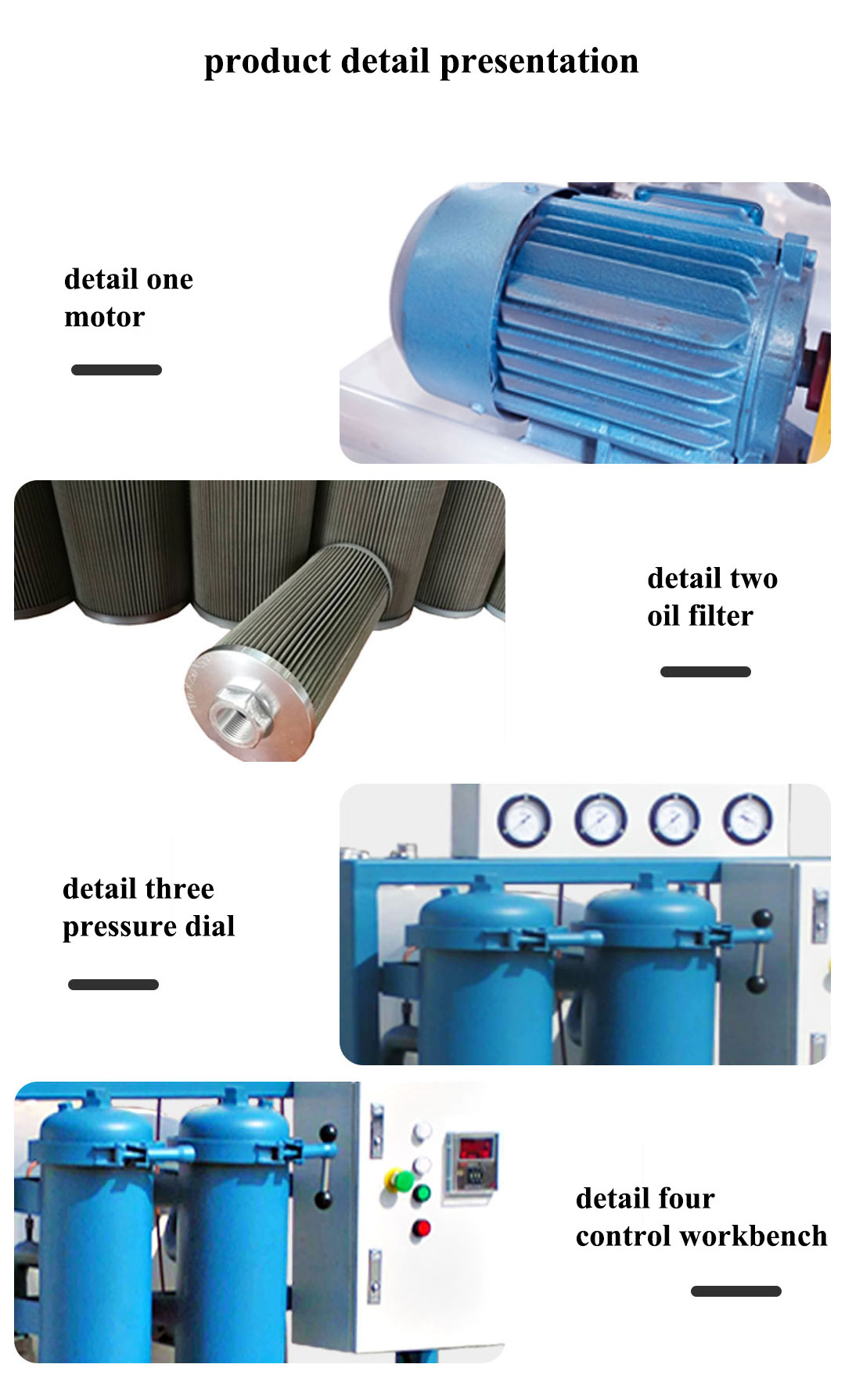

The vacuum oil purifier is designed according to the different boiling points of water and oil. It consists of a vacuum heating tank fine filter, a condenser, a prefilter, a water tank, a vacuum pump, an oil drain pump and an electrical cabinet. The vacuum pump draws out the air in the vacuum tank to form a vacuum. Under the action of atmospheric pressure, the external oil enters the pre-filter through the inlet pipe, cleans the larger particles, and then enters the heating tank. After heating, the oil at 40~75 ℃ passes through. Automatic oil float valve, this valve is to automatically control the balance of oil in and out of the vacuum tank. The heated oil is separated into a semi-mist by the rapid rotation of the jet wing, and the water in the oil is rapidly evaporated into water vapor and continuously sucked into the condenser by the vacuum pump. The water vapor entering the condenser is cooled and then returned to the original water and released. The oil in the vacuum heating tank is discharged into the fine filter by the oil discharge pump to filter out the particulate impurities through the oil filter paper or filter element, so as to complete the vacuum oil filter quickly. The whole process of removing impurities, moisture and gas in the oil makes the clean oil drain out of the machine from the oil outlet.

1. Small size and light weight.

2. Using vacuum to feed oil, a tubular rotary fuel injector is installed, which reduces the resistance, accelerates the rotation speed, and increases the effect of oil and gas separation.

3. The function of deteriorating oil purification has been added, and the silica gel purification system has been added, and the silica gel purification and impurity filtration are integrated into one.

4. There are two filtration methods for the oil purifier part: one is the traditional oil filtering method - filter paper is used as the filter medium; the other method is the fine filter element that does not require filter paper as the oil filter medium.

5. One machine is multi-functional. When used on site, the original oil-carrying equipment is used as the oil storage tank, so that the hot oil is circulated among the equipment, and various functions are performed simultaneously.

Two-stage vacuum oil filter

Similar ProductsVIEW MORE >