Turbine oil vacuum oil filter is widely used in power, chemical, paper, metallurgy and other industries of steam turbines, gas turbines, water turbines in severely emulsified turbine oil, low viscosity lubricating oil and hydraulic oil online processing

Turbine oil vacuum oil filter is widely used in power, chemical, paper, metallurgy and other industries of steam turbine, gas turbine, water turbine in the seriously emulsified turbine oil, low viscosity lubricating oil and hydraulic oil online processing, using polymer materials as the medium, set emulsification, dehydration, impurity removal as one, combined with vacuum separation technology online demulsification, dehydration, acid, impurity removal, ** Remove the moisture, gas and impurities in the oil, so that the quality index of the oil can meet the new oil standard, and ensure the best operation of the steam turbine unit.

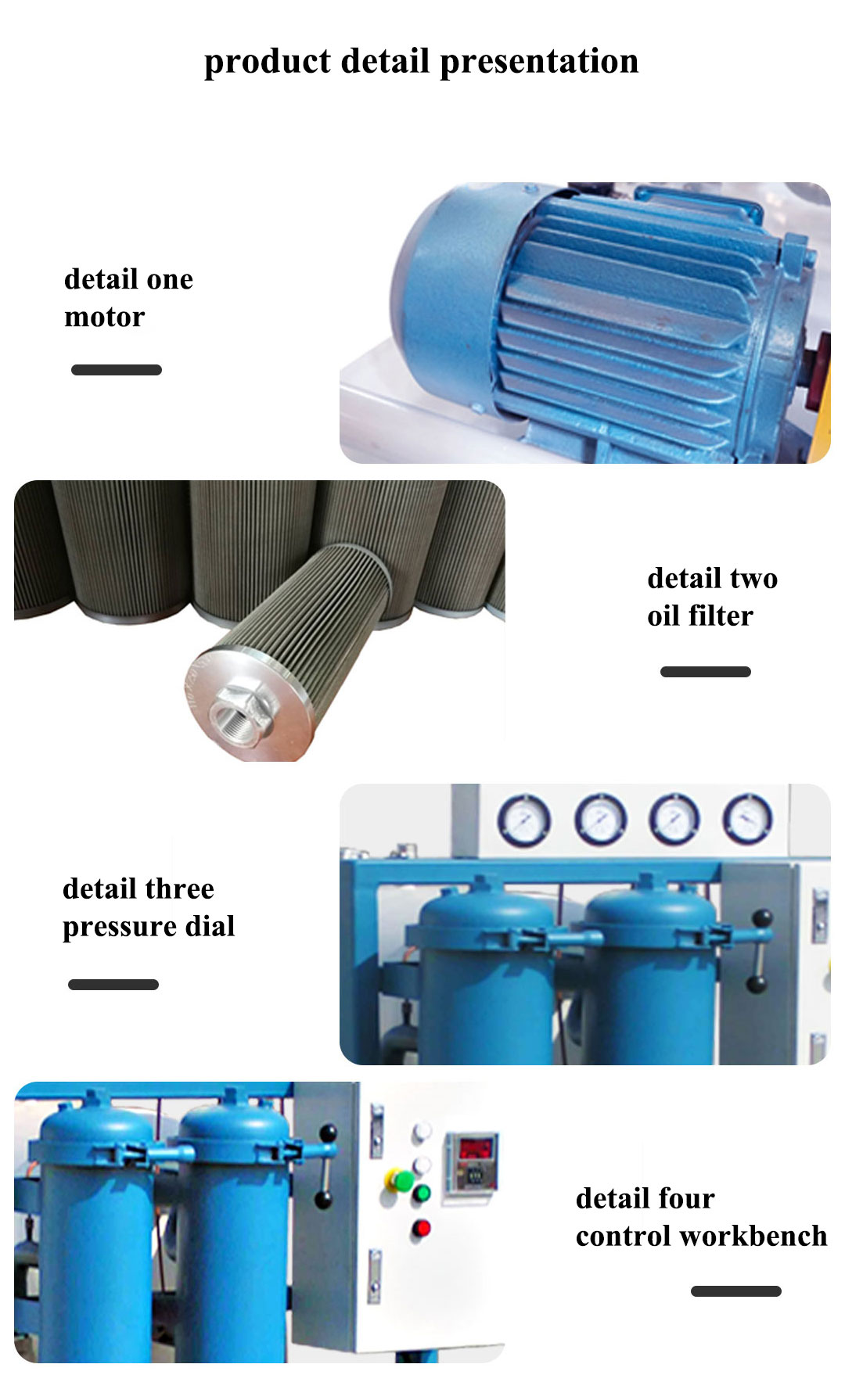

Turbine oil vacuum filter is composed of main filter, heating system, fine filter, condenser, vacuum tank, fine filter, water tank, vacuum pump, oil pump and so on. The vacuum pump extracts the air in the vacuum tank to form a vacuum, the outer oil acts under atmospheric pressure, goes through the intake pipe into the main filter to remove large particles, and then into the heating tank. After heating, such as 40 ~ 75°C, oil enters the vacuum tank through a solenoid valve which automatically controls the amount of oil flowing in and out of the vacuum tank. The heated oil becomes an oil mist and enters the vacuum tank. The water in the oil quickly evaporates into a steam sprayer and is sucked into the condenser of the vacuum pump. Water vapor passes through the back of the condenser to the liquid water and discharges. The gas in the oil is quickly discharged by a vacuum pump. After the vacuum tank, the oil passes through a fine filter to separate granular impurities, and then the clean oil is discharged.

1. Vacuum filter of turbine oil adopts coagulation method, gasification method, vacuum separation, mechanical filtration, automatic emulsification and other technologies, with high dewatering and emulsifying efficiency.

2. Advanced infrared level automatic control system, sound and light automatic alarm system, pressure protection device, to ensure the stable operation of the whole machine.

3. Compound negative pressure flash technology to completely remove liquid water, but also remove **** free water and 80% of the dissolved water.

4. Humanized design, low noise, easy operation, long maintenance interval, low energy consumption, save running costs.

5. On-line oil filter, no one can run, running state is displayed by the indicator light.

6. The differential pressure type automatic backwashing system eliminates the complicated manual disassembly and washing.

TY series special vacuum oil filter for turbine oil

Similar ProductsVIEW MORE >