Power plant special insulation oil filter is mainly used for 110KV above large electrical transmission and transformation equipment and national main transformer network, transformer on-site maintenance of large substations and new oil, imported oil and other insulating oil rapid and in-depth processing

Power plant special insulation oil filter is mainly used for 110KV above large electrical transmission and transformation equipment and national main transformer network, transformer on-site maintenance of large substations and new oil, imported oil and other insulating oil rapid and in-depth processing. The product has the company's unique process and world advanced technology, widely used in power plants, power stations, electric power companies, metallurgy, petrochemical, machinery, transportation, railway and other industries.

On the basis of retaining all the advantages of ZWB series vacuum oil filter, Roots vacuum booster system, second high vacuum pumping system and microcomputer vacuum detection system are added, overcoming the weakness of the vacuum oil filter in high vacuum when the exhaust volume drops sharply, one cycle is equivalent to the effect of two ordinary vacuum oil filters.

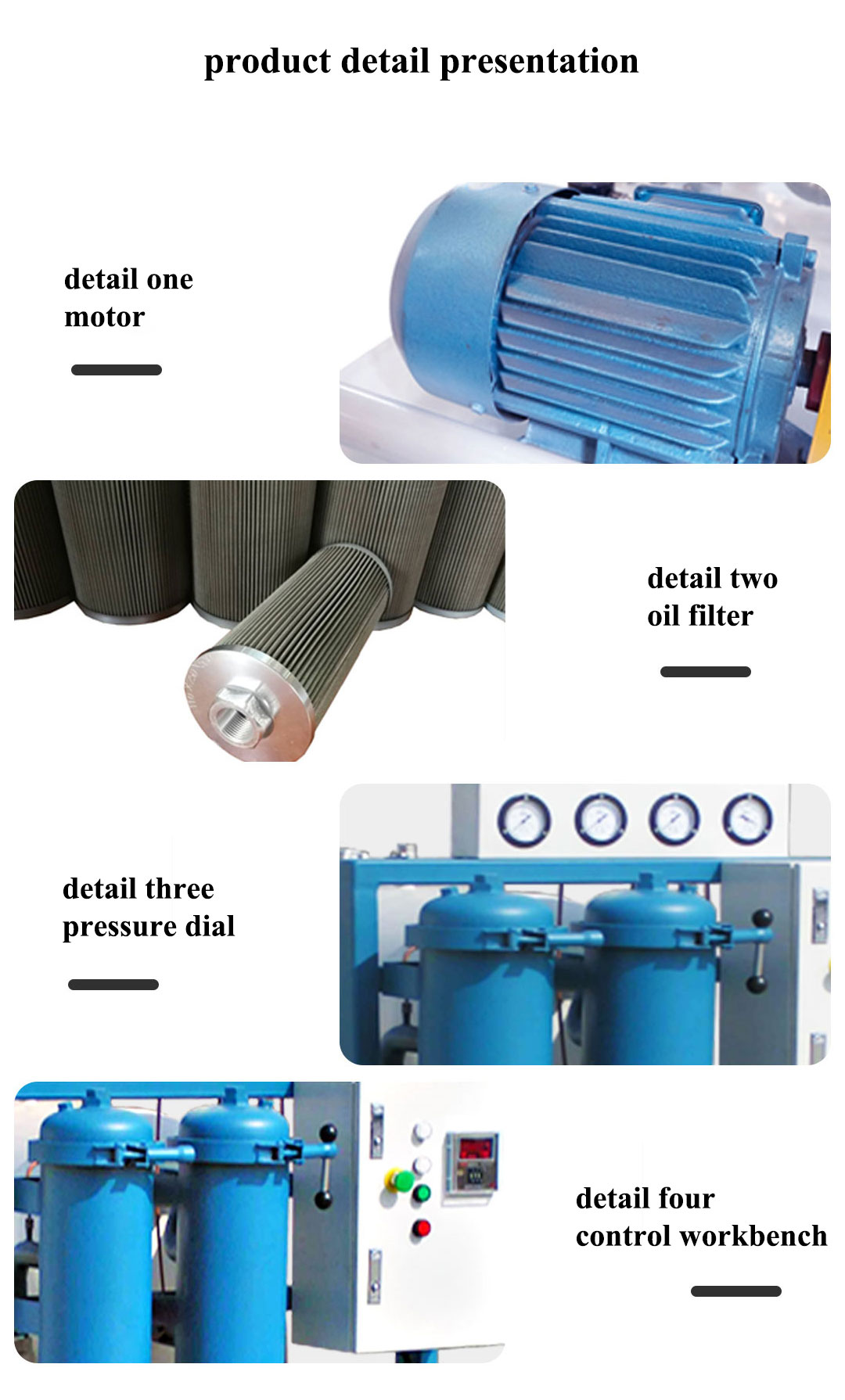

Superior technology:

The unique manufacturing process of Runxiang company is adopted. Compared with the single vacuum oil filter, the dehydration, degassing and impurity removal effect is faster and more thorough, and the oil ultimate pressure tolerance value is higher. It is an advanced technology in this industry, which can be used as a vacuum oil filter, and can also be used as an independent vacuum source for vacuum oil filling of power insulation equipment.

Oil index after treatment

Oil breakdown voltage kV 75

Water content PPm in oil ≤3 ~ 5

Gas content in oil % ≤0.1

Impurity size um 1 ~ 5 without free carbon

1. Double-stage high vacuum system, large pumping speed, high working vacuum. Limit vacuum ≤5Pa, working vacuum ≤35Pa; Limit vacuum ≤5Pa, working vacuum ≤35Pa.

2. Two-stage vacuum separation chamber and oil atomizer are adopted to increase the separation area and separation time to ensure that the drying degree and pressure resistance value of oil are greatly improved. Can quickly remove all kinds of water, gas. Make sure the acetylene is 0.

3. Compound stereo flash, with unique dehydration, degassing element, can quickly and effectively separate the water and gas in the oil.

4. Multistage precision filtration system, molecular adsorption filtration and mesh filter element combination of impurity removal technology.

5. New electric heating system, low heating load, uniform heating, less energy consumption.

6. Automatic infrared level control instrument, pressure protection system, simple operation, safe and reliable.

7. Use the whole machine interlock protection device, heater, oil pump, liquid level controller linkage work.

8. Transformers can be on-line drying, on-line vacuum filtration.

9. High performance pumping system, stable oil output under high vacuum, low noise.

10. Photoelectric foam sensor, automatic defoaming function, prevent oil injection, oil running phenomenon.

11. Digital display intelligent temperature controller, can set the upper and lower limits of heating temperature, stable control, temperature display is more intuitive. Temperature probe directly detect oil temperature, temperature sensitive, accurate, no hysteresis phenomenon.

12. For the equipment with large heating power, grouping control heating or multistage step heating and independent control of multi-temperature controller are adopted. Grouping heating can be selectively input according to the actual situation of the site; Multistage heating can automatically control the heating power input according to the setting and timely oil temperature. It can not only heat the whole power quickly when the oil temperature is low, but also run automatically with low power to maintain the oil temperature when the oil temperature reaches the preset temperature, so that the equipment is more energy saving and avoid the oil temperature overheating and carbonization.

13. The whole machine is equipped with overpressure, overcurrent, overload and anti-dry burning protection measures to ensure the operation of the equipment.

Special insulation oil filter for power plant

Similar ProductsVIEW MORE >