Transformer oil online oil filter filter function quickly remove the water, gas, impurities in the insulation oil, reduce dielectric loss, improve the insulation performance of oil and oil quality, can be randomly detected pressure value and automatic printing test results (ZJB-T series). It can effectively ensure the normal operation of power equipment and avoid accidents

Transformer oil online oil filter filter function quickly remove the water, gas, impurities in the insulation oil, reduce dielectric loss, improve the insulation performance of oil and oil quality, can be randomly detected pressure value and automatic printing test results (ZJB-T series). It can effectively ensure the normal operation of power equipment and avoid accidents. Vacuum oil filter can satisfy the installation or maintenance site of the transformer body vacuum, and complete the transformer oil degassing, dehydration treatment, shorten the duration of oil treatment. It sets oil precision filtration, dehydration, degassing, vacuum stereoscopic evaporation technology and automatic control technology in one, simple operation, reliable operation.

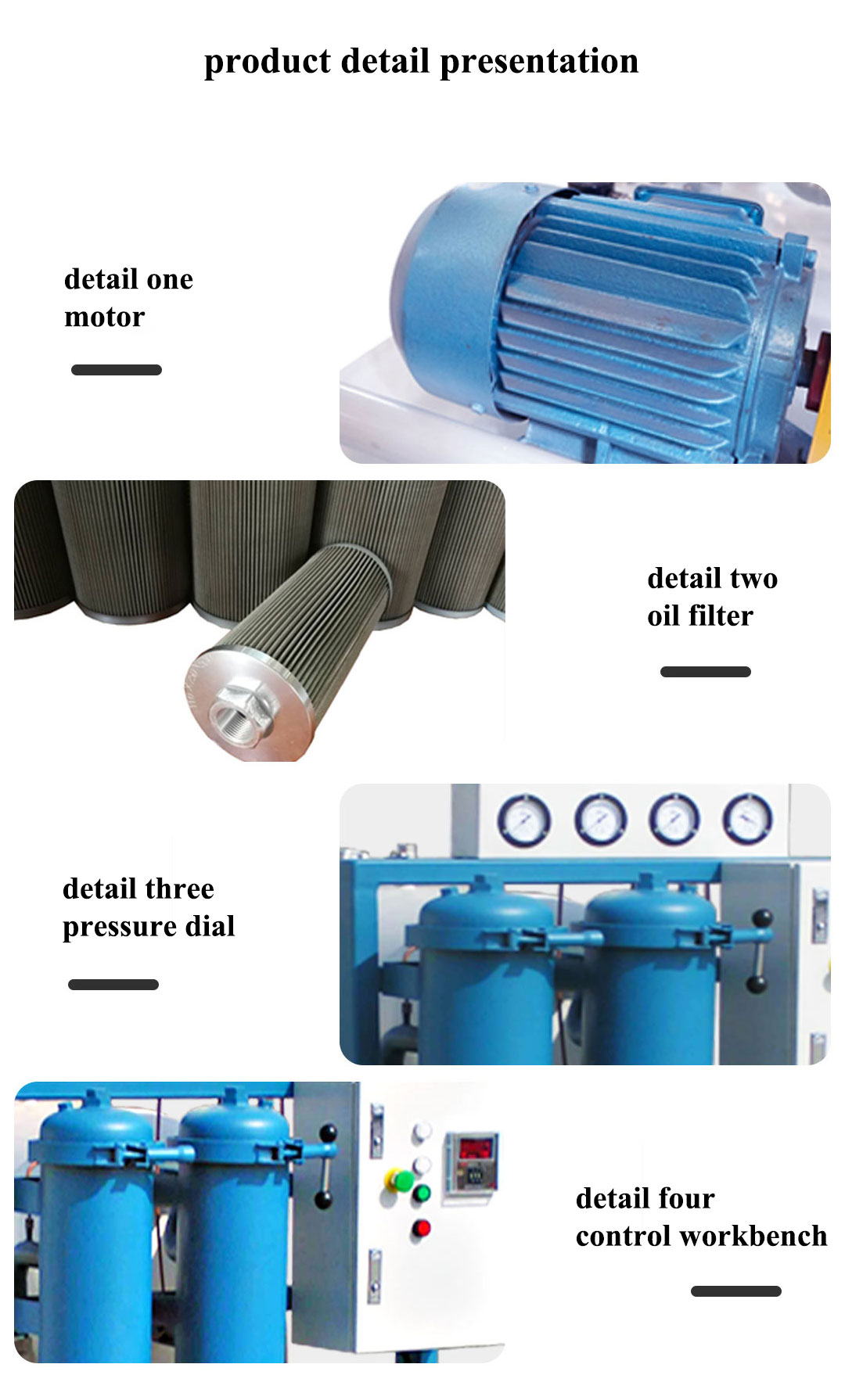

When the equipment is working, the oil enters the primary filter through the entrance under the action of internal and external pressure difference, and the large particles of impurities are filtered out. After multistage infrared heating, the oil enters the special and personalized vacuum separator. In the vacuum separator, the mist shape is formed first, and then the film shape is formed, so that its contact area in the vacuum is expanded to hundreds of times the original. The moisture and other harmful gases in the oil are quickly vaporized and discharged by the vacuum system under the condition of high heat, high vacuum, large surface and high pumping speed.

The water vapor discharged from the upper part of the vacuum separator is first cooled by the condenser and dehumidified, and then cooled again in the cooler. The condensate water is discharged into the water storage device. After two condenses and dehumidification, the gas is discharged into the air by the vacuum pump.

The dry oil after vacuum vaporization and dehydration in the vacuum separator increases from negative pressure to positive pressure through the oil transport pump. After filtration, the net oil is discharged from the oil outlet to complete the whole clean oil process.

When the oil filter works, it is necessary to filter the oil under the action of atmospheric pressure and vacuum suction. The strong magnetic filter is sucked through the strong magnetic filter element, and the impurities and metal chips of large particles are filtered out. After the oil containing fine impurities is heated by the heater, the oil enters the three-dimensional vacuum flash tower. Under the action of the spray device, the oil is dispersed into a mist and sprayed onto the three-dimensional flash Pall ring to form a very thin oil film (thickness 0.025mm), which makes the curve of the oil film move downward, resulting in a large aeration area and a time retention process of aeration, so as to carry out a full separation process of demulsification, dehydration and degassing. The evaporated water is discharged through the drainage valve, and the gas is discharged through the vacuum pump. After the removal of water and gas oil through the oil pump into the secondary filter and precision filter, filter out the particulate impurities in the oil, that is, clean oil for purification. The whole purification process is completed.

ZJB-30 transformer oil on-line oil filter

Similar ProductsVIEW MORE >