Two-stage vacuum oil filter is an ideal equipment for on-site maintenance of insulating oil for all kinds of high and low voltage (below 500kV) power transmission and transformation equipment.

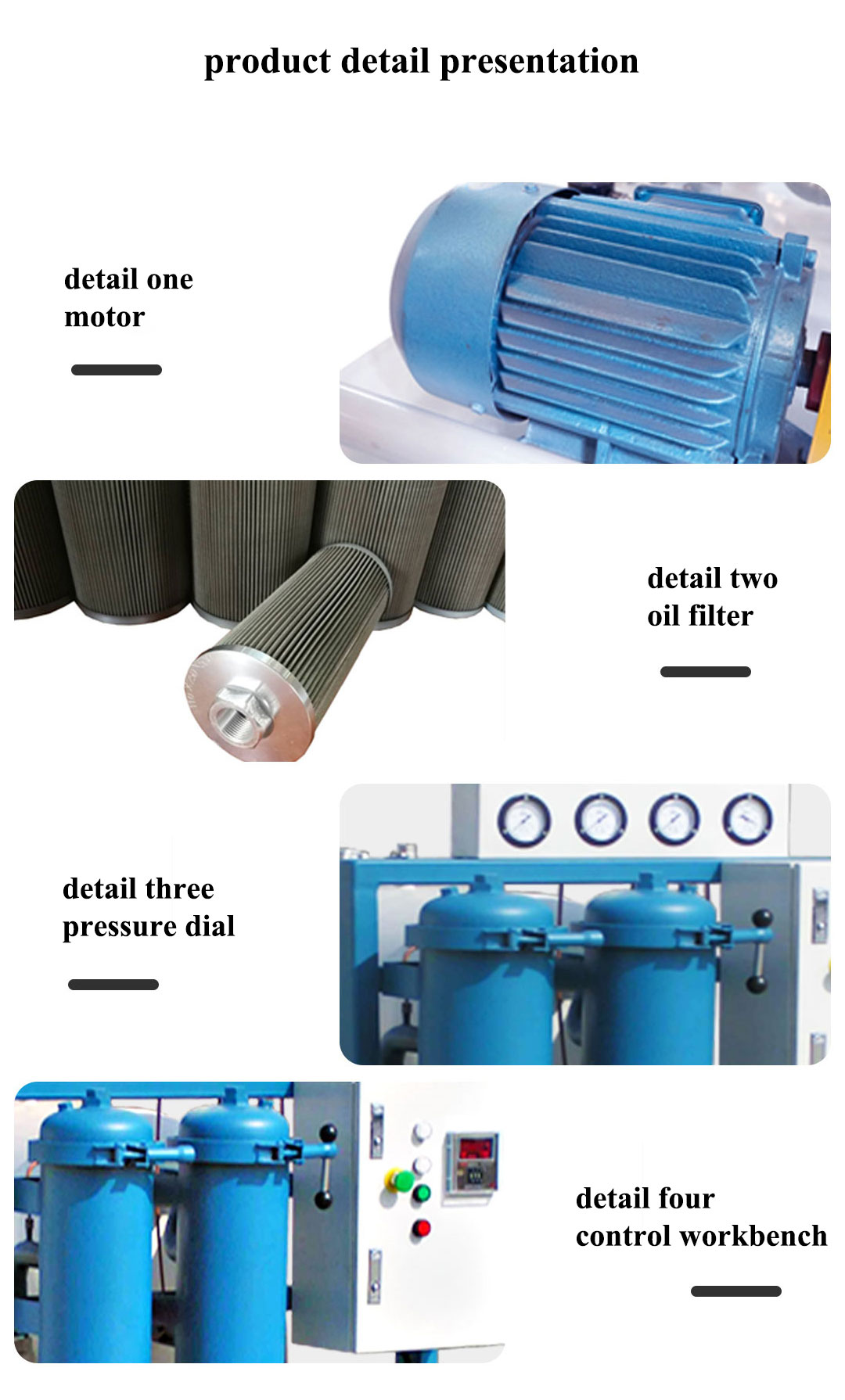

Two-stage vacuum oil filter is an ideal equipment for on-site maintenance of insulating oil for all kinds of high and low voltage (below 500kV) power transmission and transformation equipment. The series of products, easy to move, the technical indicators reach the index, the use of fully closed oil filter, live operation, can dry the moisture in transformer and other equipment at the same time, widely used in power plant, power station, substation, industrial and mining enterprises to purify transformer oil, turbine oil, hydraulic oil, transformer oil, switch oil, freezing oil and other oil in the water, gas and impurity particles. The degassing components adopted by the manufacturer can greatly improve the efficiency of dehydration and degassing. The advanced photoelectric control defoaming device is adopted. The oil level is controlled by mechanical and electronic control and overpressure alarm device, which can realize automatic operation. The oil inlet and outlet has the function of interchanging. The oil inlet and outlet can be exchanged freely through the valve control in operation, without disassembling the oil pipe. Using low power high density electric heating element, with overheating protection system, in any case will not cause oil deterioration phenomenon, the whole system without cooling, easy to use, winter use, replace the filter element without tool disassembly.

In order to meet the needs of power maintenance department on-site maintenance of all kinds of high and low pressure oil equipment, we refer to the technology of Japan Kato Company, strictly implement the national standard DL/T521-2004 vacuum oil cleaner as the guide, the design has the characteristics of small volume, light weight, easy to move, low noise, long continuous working time, stable performance, convenient operation and so on.

⊙High vacuum, large pumping speed, the combination of circular three-dimensional compound flash technology and microgram technology at home and abroad, can quickly remove water, dissolved water, free carbon, gas and other harmful components.

⊙Adopting the impurity removal technology combined with multi-layer polymer mesh filtration and strong magnetic electrostatic adsorption, the filtration area is large, the pollution carrying capacity is strong, the filtration accuracy is high, ß3≥1000.

⊙Compound three-in-one protection device can make high and low oil level automatic protection, infrared detection automatic defoaming, automatic level control, automatic constant temperature, automatic pressure protection, high degree of automation, sensitive and reliable operation.

⊙ Especially suitable for vacuum oiling, large vacuum pumping and vacuum drying of transmission and transformation equipment above 110KV at installation or maintenance site.

⊙The advanced process design of the oil purification equipment, can be online or offline processing and oil filtering, can be unattended, the running state is displayed by the indicator light.

⊙Humanized design, low noise, simple operation, long maintenance interval, low energy consumption to save running costs.

⊙ In addition to filter the net oil function, the equipment can also be converted to the valve for independent pumping, oil filling, oil filling function, oil transmission at the same time to filter the particles, in order to meet the field multi-purpose use requirements.

Bipolar vacuum oil filter

Similar ProductsVIEW MORE >