Vacuum is mainly composed of the following systems: oil intake filter system; Vacuum pumping system; Vacuum failure system; Vacuum spray system; Oil filter system and recoil system; The vacuum oil filter has two functions of removing water and impurities, flocculent and metal particles in the oil at a low temperature.

When the vacuum oil filter works, the insulating oil that needs to be filtered under the action of vacuum suction enters the strong magnetic filter (filtering accuracy 80 µl), filters out large particle impurities, and then enters the heater for heating (20º-80º). The hot oil changes from the spray device into a coarse particle mist into the three-dimensional vacuum flash tower, and the water begins to evaporate, and the oil mist falls to the three-dimensional flash pall ring. A very thin oil film (thickness 0.025mm) is formed, and the curve of the oil film moves downward, resulting in a large aeration area and a time retention process of aeration, so as to carry out a full separation process of demulsification, dehydration and degassing. Evaporating water steam, light hydrocarbon and other gases formed by the mixture of gas into the water gas separation device, precipitated water directly discharged, water steam and non-condensable gas into the vacuum buffer chamber, cooled water directly discharged, non-condensable gas discharged by the vacuum pump. After dehydration and degassing of oil products under the action of the oil pump, through the secondary filter (filtration accuracy 15 µl), three filter (filtration accuracy 5 µl) filter very fine mechanical impurities, complete a working cycle. In addition, the device can vacuum other equipment through the vacuum pumping interface.

Vacuum is mainly composed of the following systems: oil intake filter system; Vacuum pumping system; Vacuum failure system; Vacuum spray system; Oil filter system and recoil system; The vacuum oil filter has two functions of removing water and impurities, flocculent and metal particles in the oil at a low temperature.

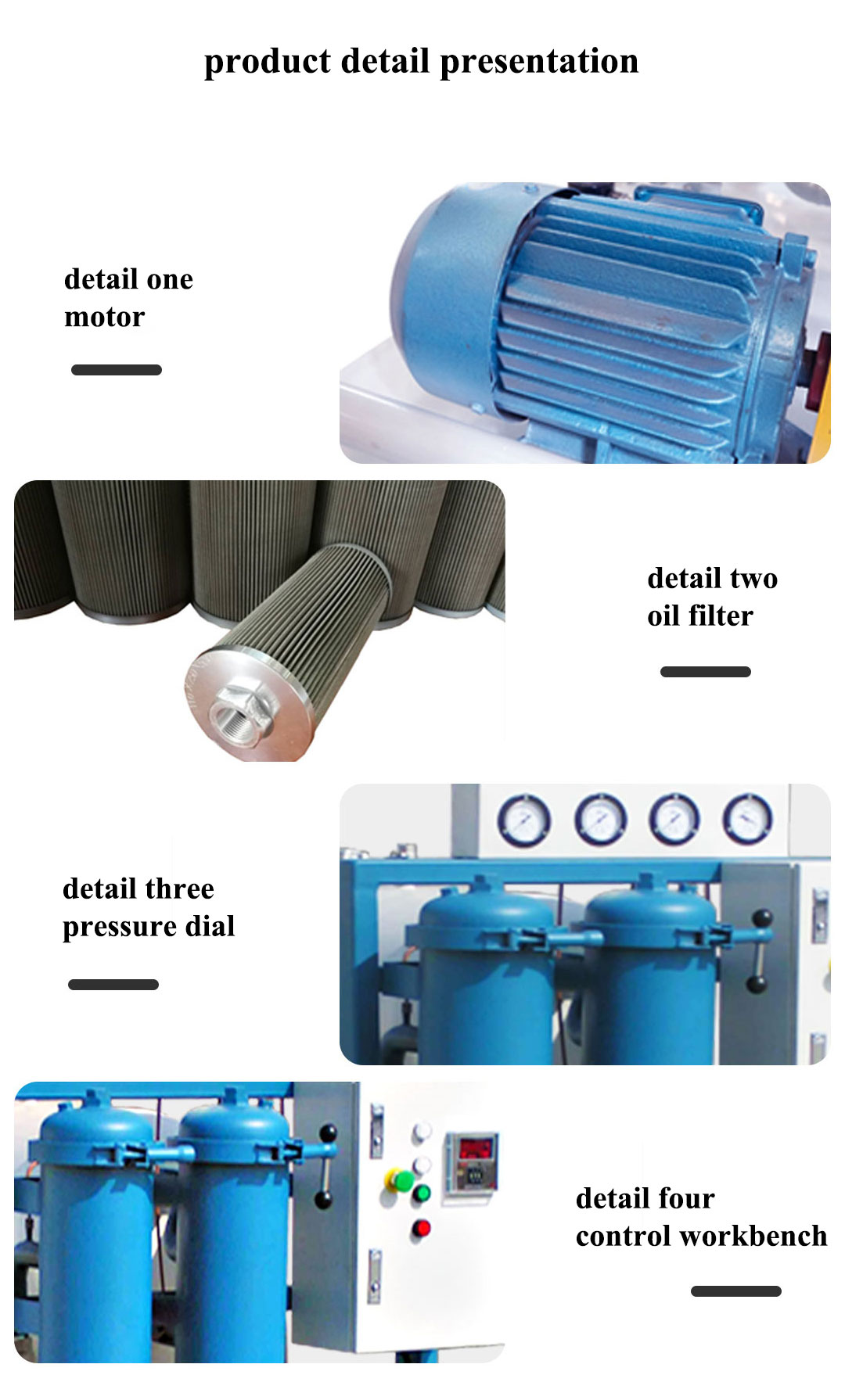

The oil intake filter system: composed of coarse filter, fine filter and special filter; Vacuum pumping system: composed of vacuum pump, water distributor, check valve and cooler; Vacuum failure system: composed of intake valve, filter dryer and vacuum failure valve; Vacuum spray system: composed of heater, vacuum tank, spray device, temperature controller and liquid level gauge; Oil filter system: by the pump, metal filter (10~20 μm), fine filter (5~10 μm), superfine filter (1~5 μm) composition; 2.1 Recoil system: When the oil pressure reaches and exceeds a certain reading (0.25MPa), the indicator will light up and alarm, indicating that the oil filter element has been seriously blocked. At this time, the recoil system should be used to clean the filter element.

Recoil can remove the accumulated pollutants on the filter element, so that the filter element can be reused, prolong the life of the filter element.

1. Double initial filter structure, increase the amount of pollution; Multistage precision filtration to ensure the filtration accuracy

2. Polymer material for the medium, set break emulsification, dehydration, impurity removal as one

3. Compound stereo flash, with unique dehydration, degassing element, can quickly and effectively separate water, gas and volatile matter in oil.

4. Automatic backwash function, improve the use efficiency

5. Advanced medium condensing system

6. Using high quality filter material, large amount of pollution, corrosion resistance, high temperature resistance, good mechanical strength, high precision in removing impurities, long service life.

7. New electric heating system, low heating load, uniform heating, less energy consumption.

8. The whole machine interlock protection device, heater, oil pump, liquid level control instrument linkage work.

Small vacuum oil filter

Similar ProductsVIEW MORE >