The FRIESS EFC electrostatic oil filter quickly and reliably removes dirt, oxidation products and other contaminants from non-conducting fluids such as hydraulic oils, transformer oils, turbine oils, lubricating oils and many other oils

The FRIESS EFC electrostatic oil filterquickly and reliably removes dirt, oxidation products and other contaminants from non-conducting fluids such as hydraulic oils, transformer oils, turbine oils, lubricating oils and many other oils. The use of electrostatic oil removal cleaners removes particles smaller than 0.1µm and removes aging in the oil, such as paint film contaminants and oxidation products. As a result, the service life and durability of the oil can be improved many times. At the same time, the machine accuracy is improved, and the hydraulic failure is greatly reduced.

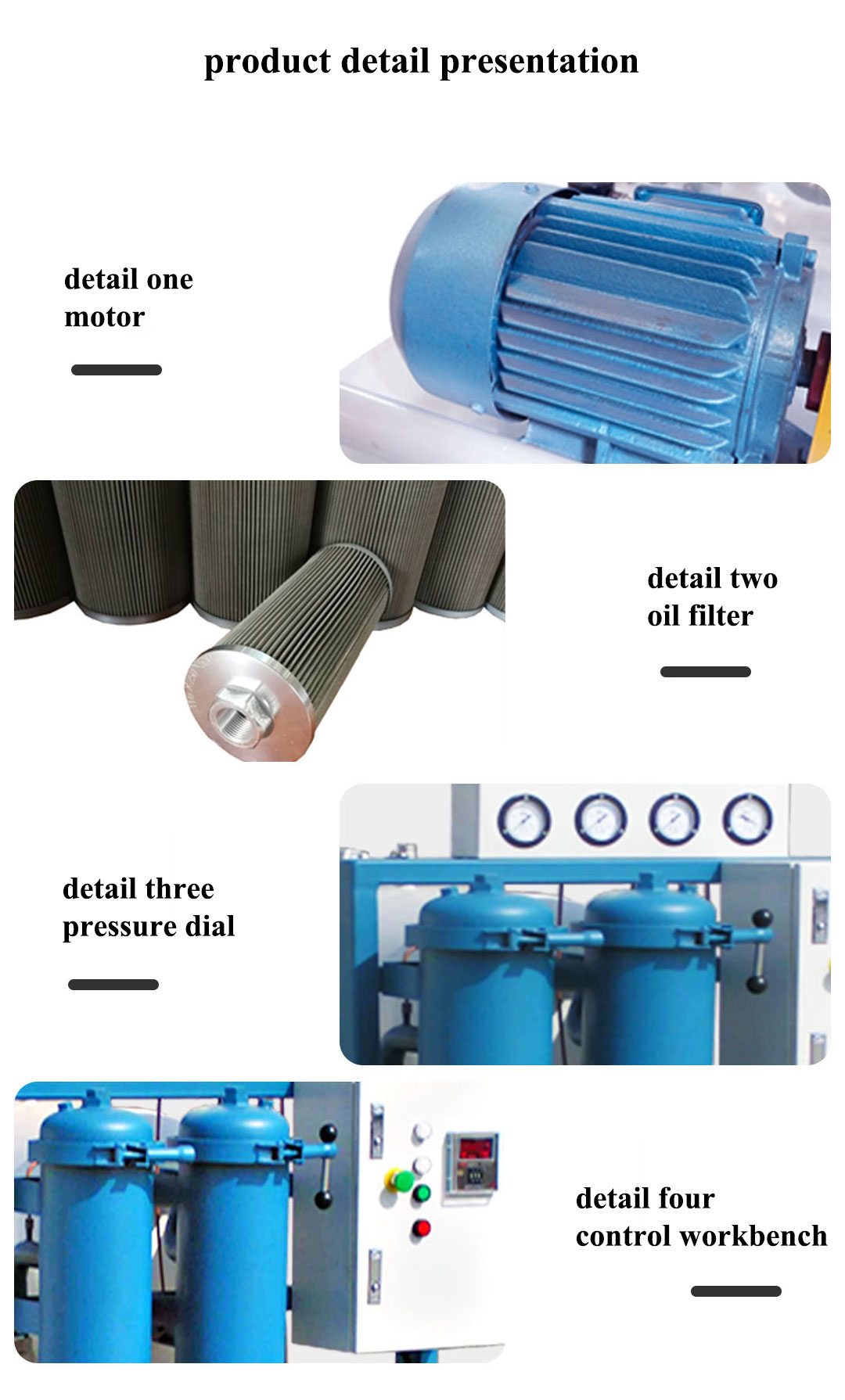

The electrostatic oil filter is connected with the pool of oil to be filtered. The oil is pumped from the main pool to the electrostatic oil filter by the gear pump. The purifying box in the oil filter is equipped with 14000V high voltage electrodes. The purifying element is installed between the high voltage electrodes. The purified oil is returned to the main tank through the filter, while the contaminated particles remain in the purifying element of the electrostatic filter.

This innovative operating principle removes not only hard contaminants such as metal particles, seal wear, and debris, but also soft contaminants such as oxidation products, paint film contaminants, and viscous sludge particles from the oil. In addition, the principle of operation does not depend on aperture as conventional filters do. The electric field force is applied to all charged particles, regardless of their size. As a result, even tiny particles and soft particles can be removed from the oil. The result is an extremely clean oil, more pure than new oil. By continuing to use electrostatic filters, our customers are able to avoid replacing oil products and simply replace leakage losses, thus greatly reducing oil costs.

The service life of hydraulic fluids can be increased to more than 100,000 working hours through consistent application of electrostatic oil purification.

Reduce fuel consumption by more than 95%

Greatly reduce the cost of equipment maintenance, repair and oil replacement

The hydraulic failure rate can be reduced by more than 70%

Enhance the reliability of production

Enhance the machining accuracy and mechanical accuracy of the equipment

Hydraulic oil (injection molding machine, press)

Turbine oil purification

Aluminum profile manufacturing and processing center

FRIESS EFC electrostatic oil filter

Similar ProductsVIEW MORE >