Hydraulic oil vacuum oil filter series automatic control system: This machine adopts a series of automatic control instruments such as frequency converter, liquid level transmitter, temperature sensor, vacuum sensor to collect all kinds of information about the operation of the equipment, which is processed by the central processor to automatically control the operation of the whole equipment and monitor the operation status of the equipment

Hydraulic oil vacuum oil filterseries automatic control system: This machine adopts a series of automatic control instruments such as frequency converter, liquid level transmitter, temperature sensor, vacuum sensor to collect all kinds of information about the operation of the equipment, which is processed by the central processor to automatically control the operation of the whole equipment and monitor the operation status of the equipment. The machine is equipped with various protection devices (overload protection, overvoltage protection, phase sequence protection, abnormal operation stop protection), which can ensure the operation of the equipment.

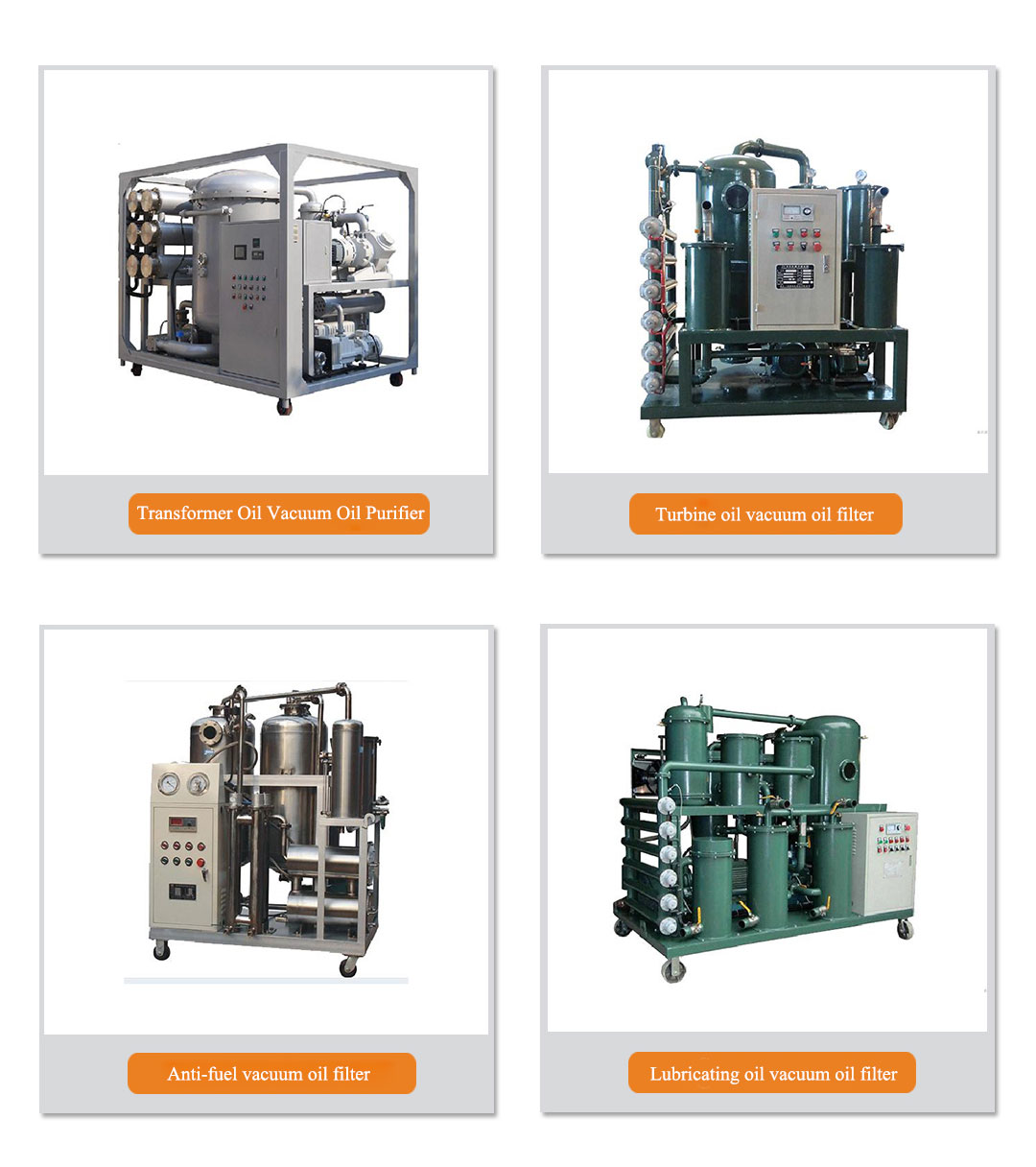

Hydraulic oil special vacuum oil filter is widely used in the manufacture of aluminum industry, steel, hydraulic press, hydraulic oil station, pump truck hydraulic oil station, engineering truck hydraulic oil station, such as unqualified lubricating oil hydraulic oil purification treatment. It is a multifunctional oil filter developed for all kinds of hydraulic oil, which can quickly remove impurities, moisture, gas, light hydrocarbon, acid value in oil, improve the quality of oil, and restore the unique performance of lubricating oil. Make serious turbidity emulsified hydraulic oil, anti-wear hydraulic oil after treatment become clear and transparent, to ensure the normal operation of the hydraulic system, power system, lubrication system.

Connect the inlet and outlet oil pipeline, connect the 380V, connect the ground wire, check whether the circuit is connected, whether the valve of the oil pipeline is opened, and then carry out the operation procedure after the preparation is intact. First start the cooling water pump, check whether the water circulation is normal, and then click the vacuum pump, so that the oil in the vacuum pump can run normally, and then make the vacuum pump run continuously. When the vacuum surface reaches the limit, the oil inlet valve can be opened. When the lower window of the vacuum cylinder sees the oil level, the switch of the oil pump can be started, and the normal circulation of the oil circuit can be started to filter impurities. The heater switch can be opened to ensure the moisture in the volatile oil. If there is more water in the oil, the oil end in the vacuum cylinder will increase. At this time, it is necessary to open the gas to control the suitable vacuum degree. When the water is reduced and the oil drifts down, the air release valve will be closed to make the vacuum reach its limit. At this time, we should pay attention to the reaction of the instrument, if the pressure gauge reading is greater than 0.3MPa, said Ming and Qing filter paper suction more impurities, need to replace the filter paper, after the work, see the working principle, open the valve, so that the vacuum degree to normal atmospheric pressure, discharge the oil in the cylinder, the rest of the oil released from the oil plug, to prevent the next use mixed with different types of oil, In winter, pay special attention to clean the water in the vacuum pump and water tank, otherwise it will freeze the vacuum pump and water storage tank.

1. switch on the power supply, must be connected to the ground wire to operate.

2. before operation, pay attention to the direction of motor rotation, to conform to the direction of the arrow.

3. no oil circulation, do not open the heater, otherwise it will burn the heater, heavy will explode.

4. All valves of the outlet pipe must be opened before oil discharge.

5. the working environment temperature is lower than -30℃, higher than +40℃, should not be used.

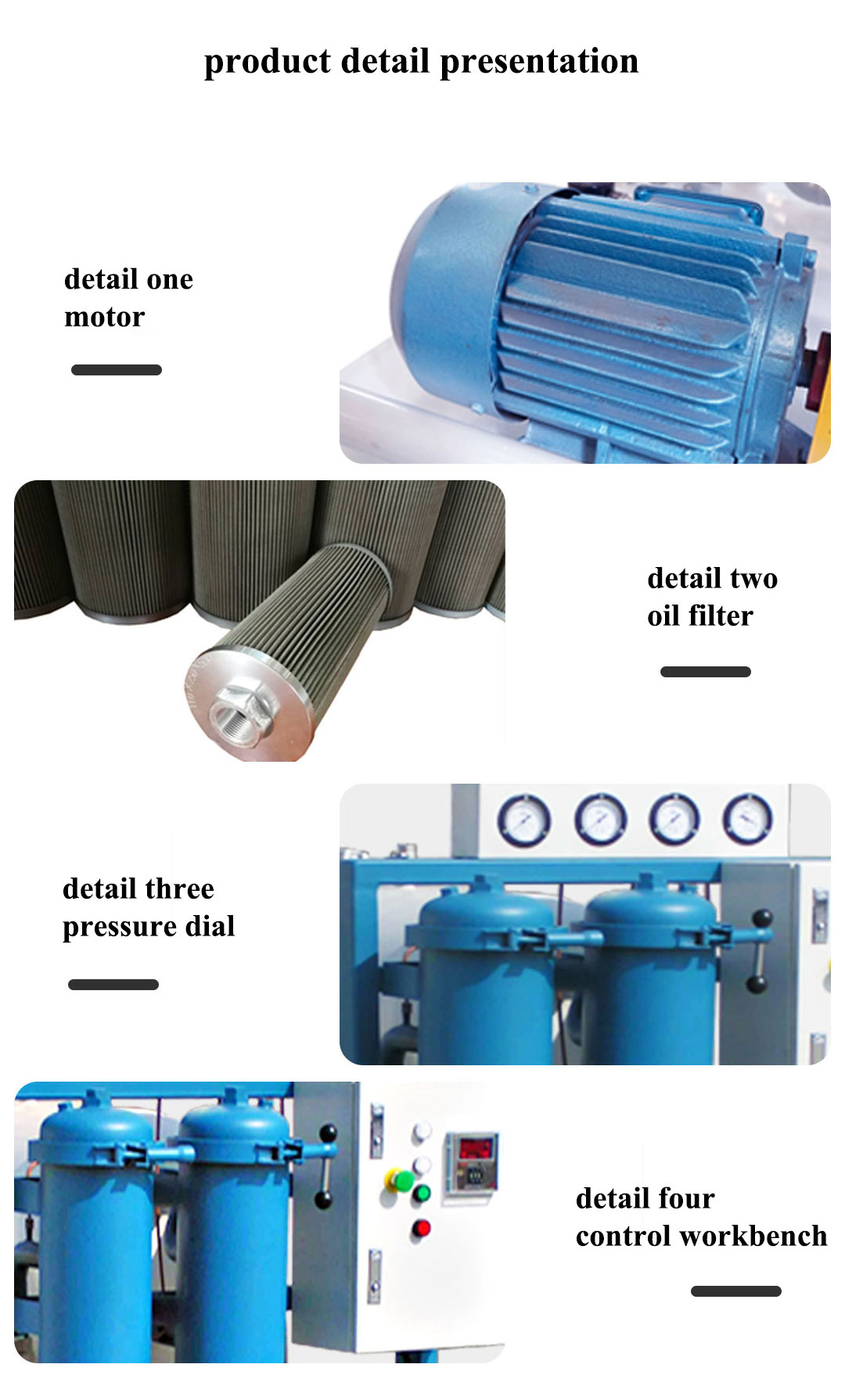

1. The machine has advanced process design, which can be connected and matched with the hydraulic tank and oil station process online processing or offline processing. It has a high degree of automation, compact volume, flexible and convenient movement.

2. Oil-water separation system; Vacuum separation using German vacuum separation technology, three-dimensional spiral atomization flash rapid evaporation technology, can quickly separate the water and gas in the oil.

3. Filtration system: advanced magnetic filter; Used for oil absorption filter, filter out solid particles and fine iron substances in the oil medium, effectively control the degree of iron impurity pollution of the working medium. High temperature resistance and good mechanical strength can meet the requirements of high heating temperature for filtering high viscosity oil and expand the range of purification oil.

4. Heating system; Reliable circulating carbon fiber heating technology is adopted to ensure uniform heating and stable oil temperature while reducing energy consumption.

5. Condensing device; Adopt advanced strong air cooling technology, medium condensing device, can quickly cool the water vapor separated from the oil, prolong the service life of the equipment.

6. Control system; The optimized design of control interlock protection device, overpressure alarm stop protection, phase sequence protection, etc., ensure the long time reliable operation of the whole machine. Automatic pressure alarm shutdown system, automatic overload protection system, automatic constant temperature system, automatic oil blowout protection and other advanced technologies ensure the full automatic operation of the equipment.

Hydraulic oil vacuum filter

Similar ProductsVIEW MORE >