In order to meet the needs of the power maintenance department for on-site maintenance of all kinds of high and low pressure oil equipment, Nuoqing refers to the technology of Kato Company of Japan and Siemens Company of Germany, strictly implements the national standard DL/T521-93-2002 vacuum oil purging machine as the guidance, the design has the advantages of small volume, light weight ratio, easy movement, low noise and long continuous working time. Stable performance, easy operation and other characteristics

In order to meet the needs of the power maintenance department for on-site maintenance of all kinds of high and low pressure oil equipment, Nuoqing refers to the technology of Kato Company of Japan and Siemens Company of Germany, strictly implements the national standard DL/T521-93-2002 vacuum oil purging machine as the guidance, the design has the advantages of small volume, light weight ratio, easy movement, low noise and long continuous working time. Stable performance, easy operation and other characteristics, is the power plant, power station, substation, electrical manufacturers, industrial and mining enterprises filter transformer oil, turbine oil, 40℃ below the oil, hydraulic oil and other oil in the water, gas and impurities in the ideal equipment.

The multifunctional oil filter has the following characteristics compared with similar domestic products;

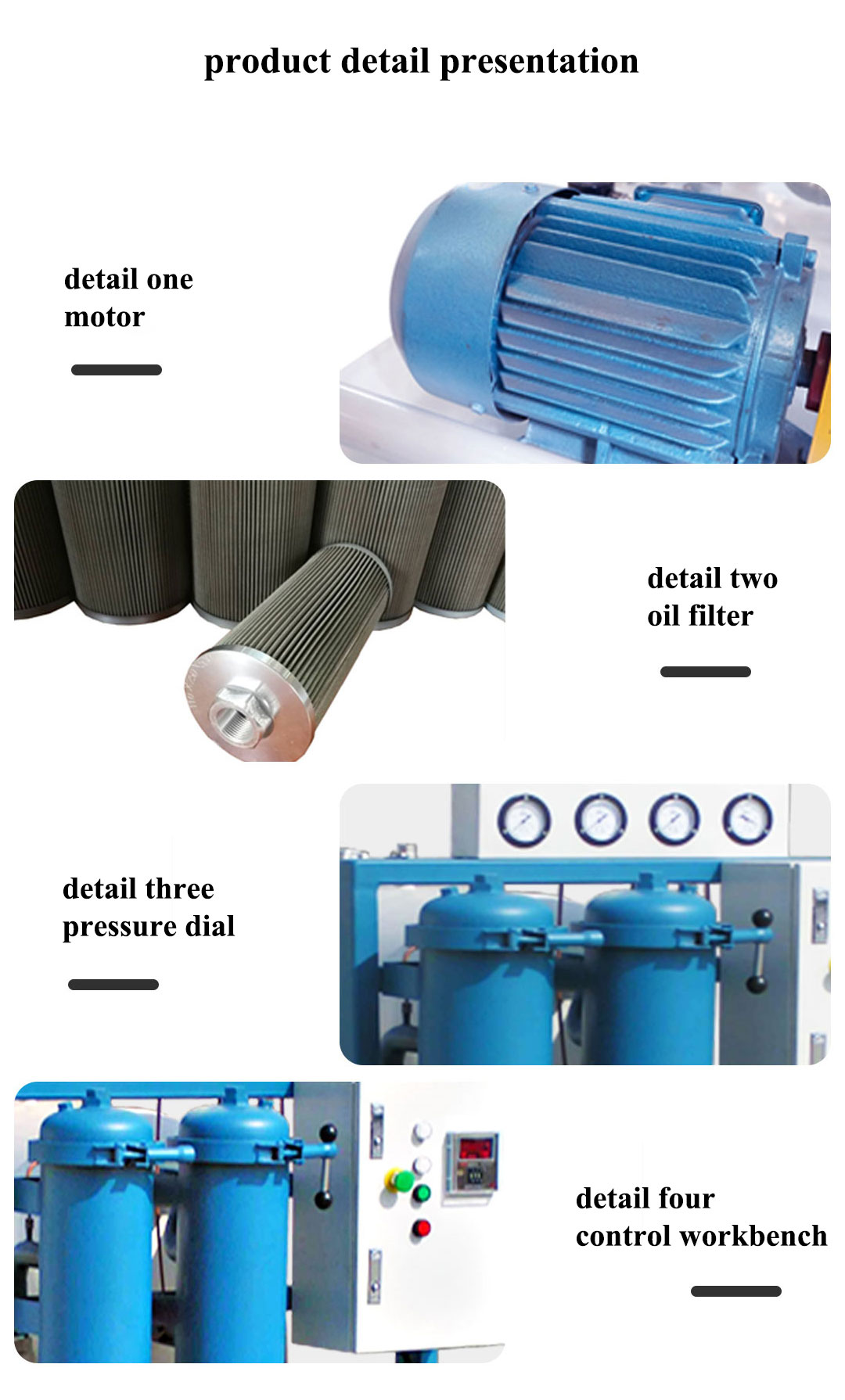

1. small size, light weight, is the weight of similar products half.

2. Improved and perfected the design of oil-gas separation. Using vacuum oil inlet, equipped with tubular rotary fuel injector, reducing resistance, fast rotation speed, increase the effect of oil and gas separation.

3. According to the needs of users, the filter medium of the oil cleaner part is made of special fine filter element, and the special fine filter element is made of non-woven dense paper. When it is found that the filtration is slow, just peel off the outer layer of non-woven dense paper.

4. One machine has multiple capabilities, which is an important feature of this machine. Because the machine is used in the field, and the original oil-bearing equipment is used as the oil storage tank, so that the hot oil circulation between the machine and the equipment, so that the three functions of oil filtration, regeneration, hot oil circulation and drying can be carried out at the same time, saving labor, saving time, and killing three birds with one stone.

1. All parts of the oil filter have been adjusted and tested before leaving the factory. It is necessary to check whether all parts are intact when transported to the site.

2. The oil filter is placed smoothly, the oil inlet is connected to the lower part of the oil tank, and the oil outlet is connected to the upper part of the oil tank.

3. Connect the power supply and ground wire to the oil filter. The power distribution cabinet, oil pump, vacuum pump and heater wiring should be checked to ensure that the connection is firm and the insulation is reliable.

4. Start the oil pump motor and observe whether it rotates clockwise (from the motor end). Otherwise switch the phase of the power supply.

5. When dealing with hydraulic oil and other mechanical oil in online operation, the same brand of oil should be properly supplemented to ensure normal oil level of the tank.

Multifunctional oil filter

Similar ProductsVIEW MORE >