3M polypropylene pleated filter cartridges are made of non-woven fabrics.

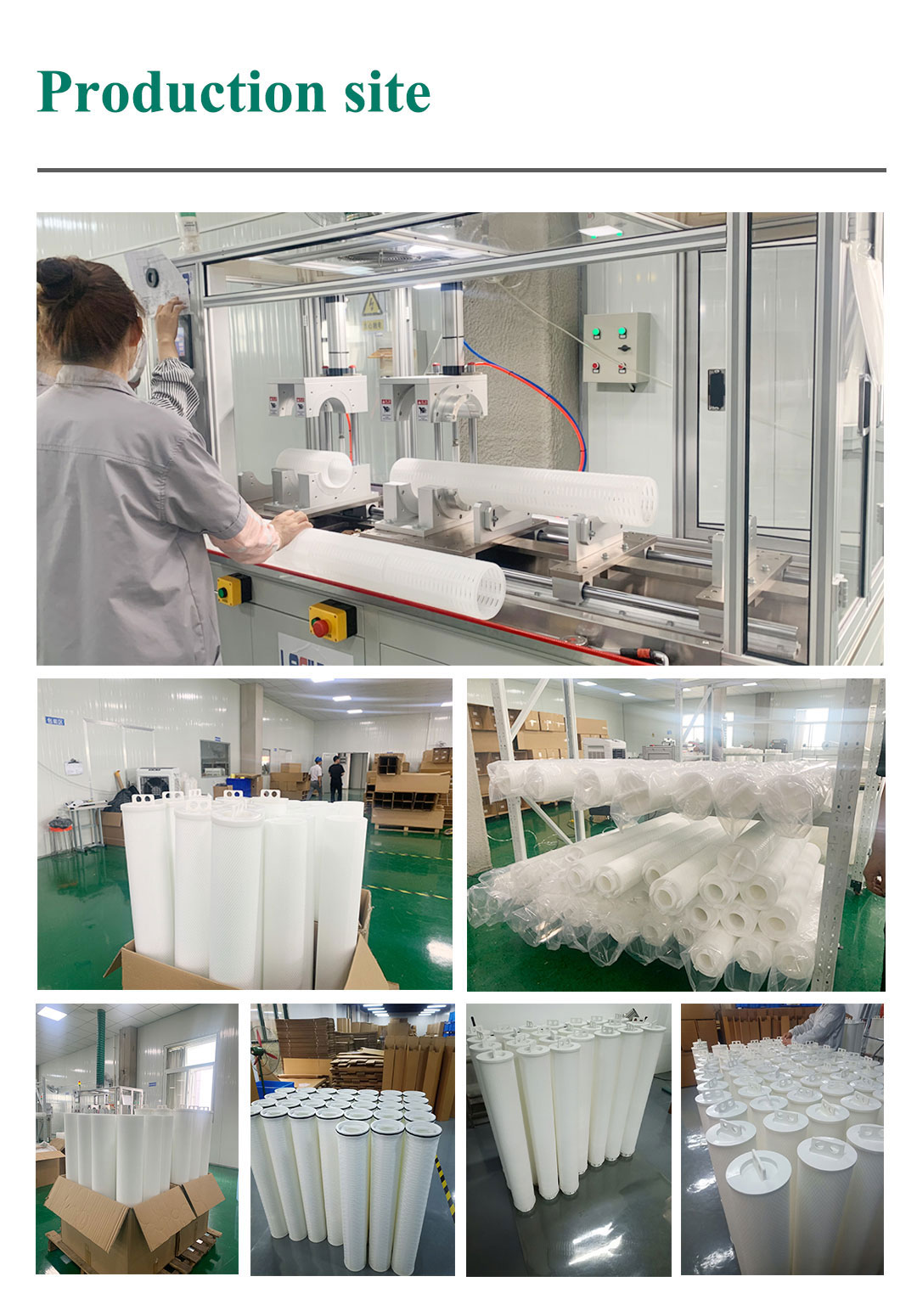

3M polypropylene pleated filter elements are made of non-woven fabrics. A single filter element can handle a flow rate of 1300LPM, which is equivalent to 10 40 inches long and 2-1/2 inches in diameter.

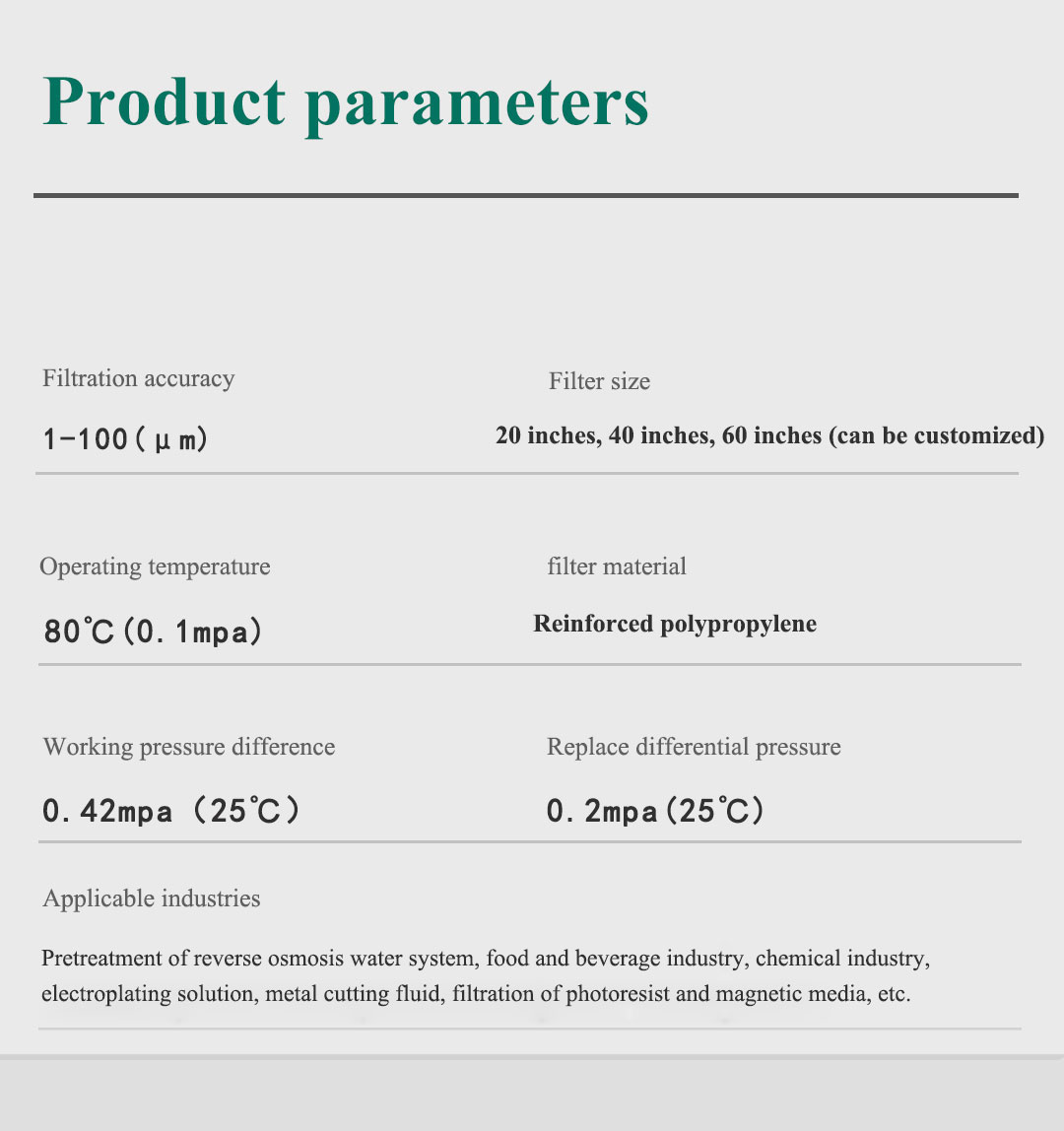

Filtration precision: 1um, 5um, 6um, 10um, 20um, 40um, 70um, 100um

Operating temperature: 82°C

Pressure drop: 3.4bar

Recommended capacity: 1300LPM

Filter material: PP polypropylene, glass fiber

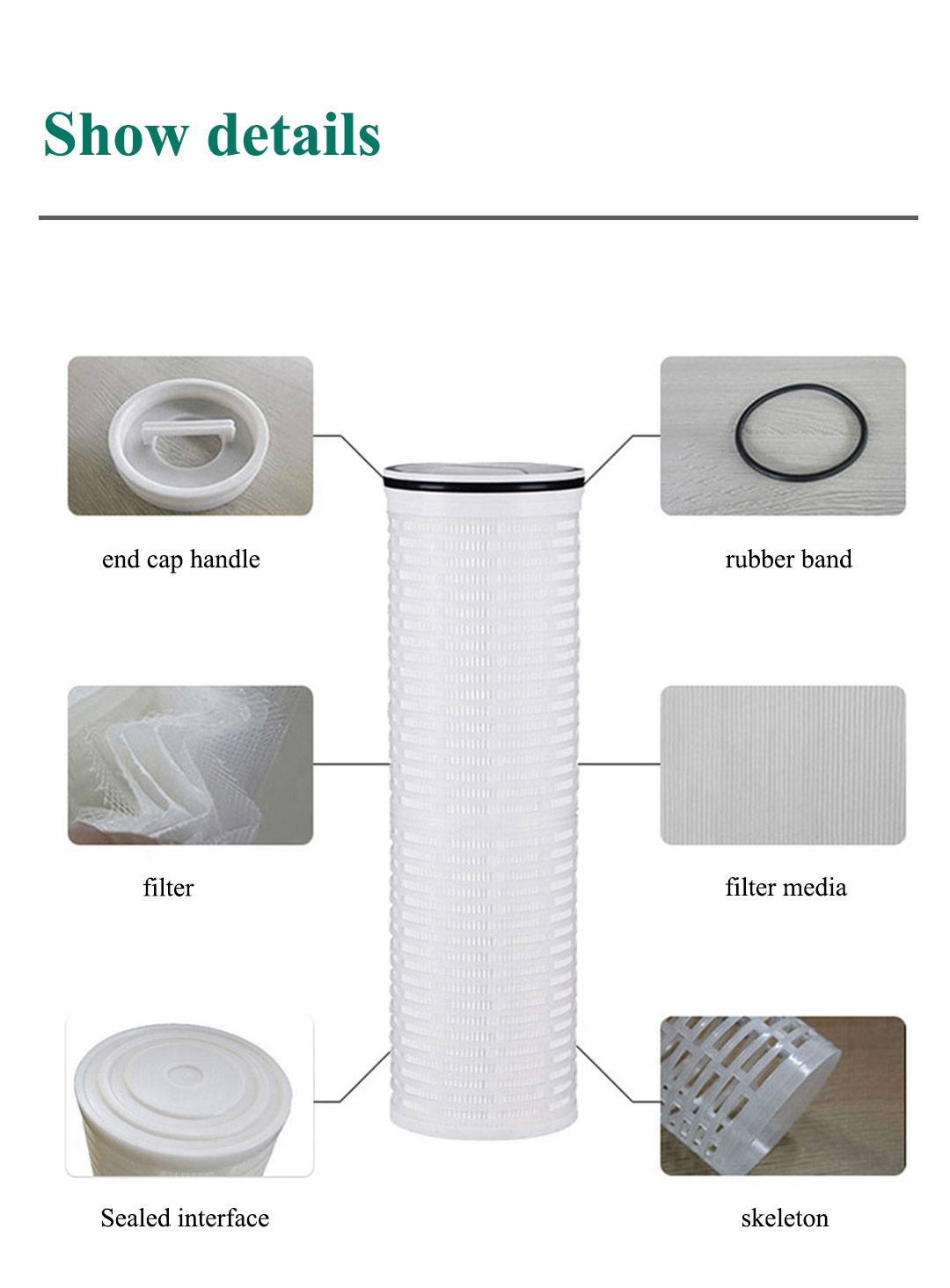

Support / Diversion Layer: Polypropylene

End cap material: glass fiber reinforced polypropylene

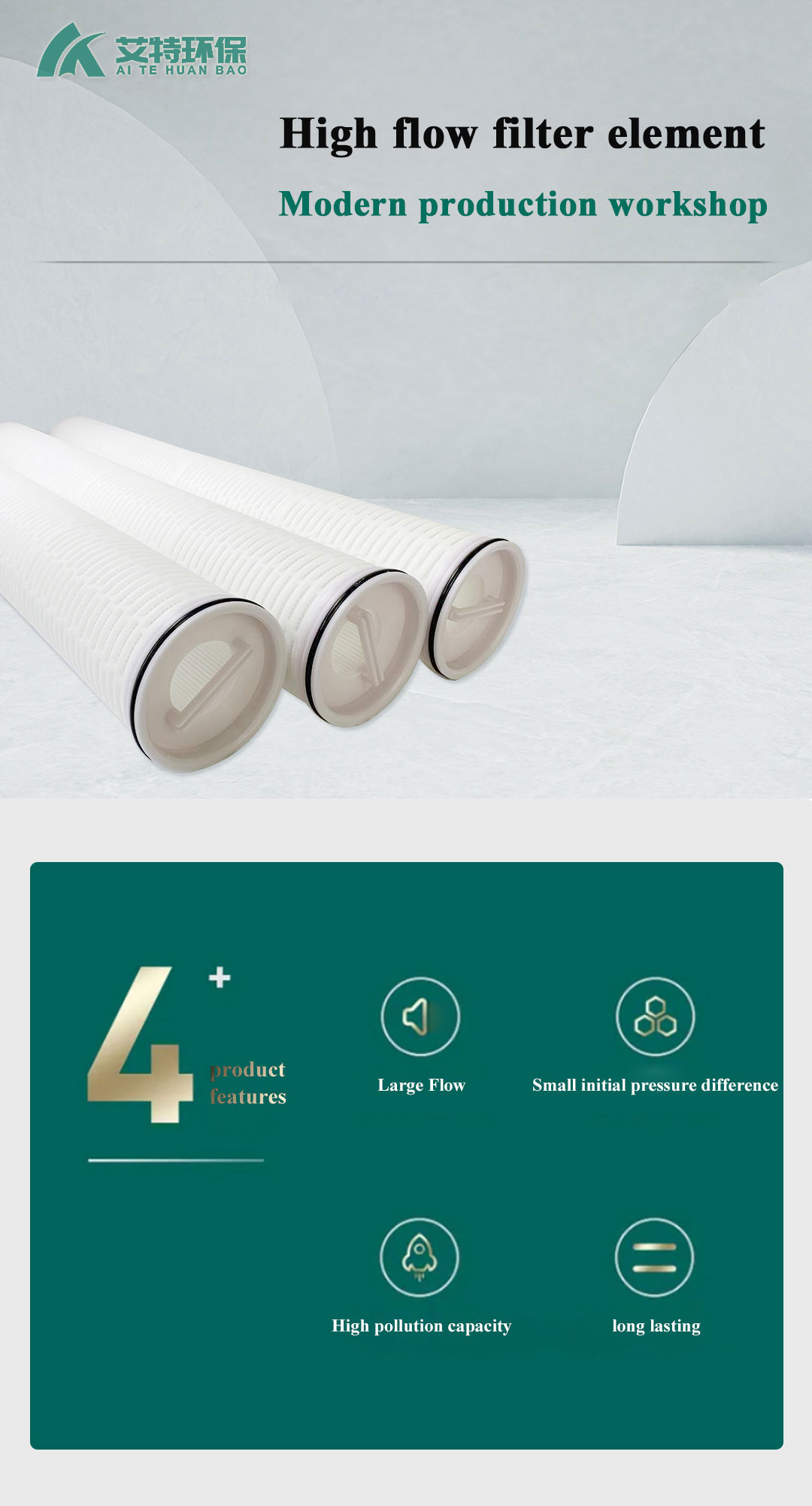

1. The filter element has a large amount of dirt and a long service life;

2. Fewer replacements to reduce operating costs;

3. The design of the sealing interface reduces the risk of side flow and improves the filtering effect and efficiency;

4. A wide range of chemical applicability can be applied to a variety of fields.

1. Filtration of condensate water in power plants;

2. Filtration of raw materials, solvents and water in the biopharmaceutical industry;

3. Filtration of mineral water, sugar liquid, edible oil, fruit juice, soft drinks, milk, etc.

3M polypropylene pleated filter element

Similar ProductsVIEW MORE >