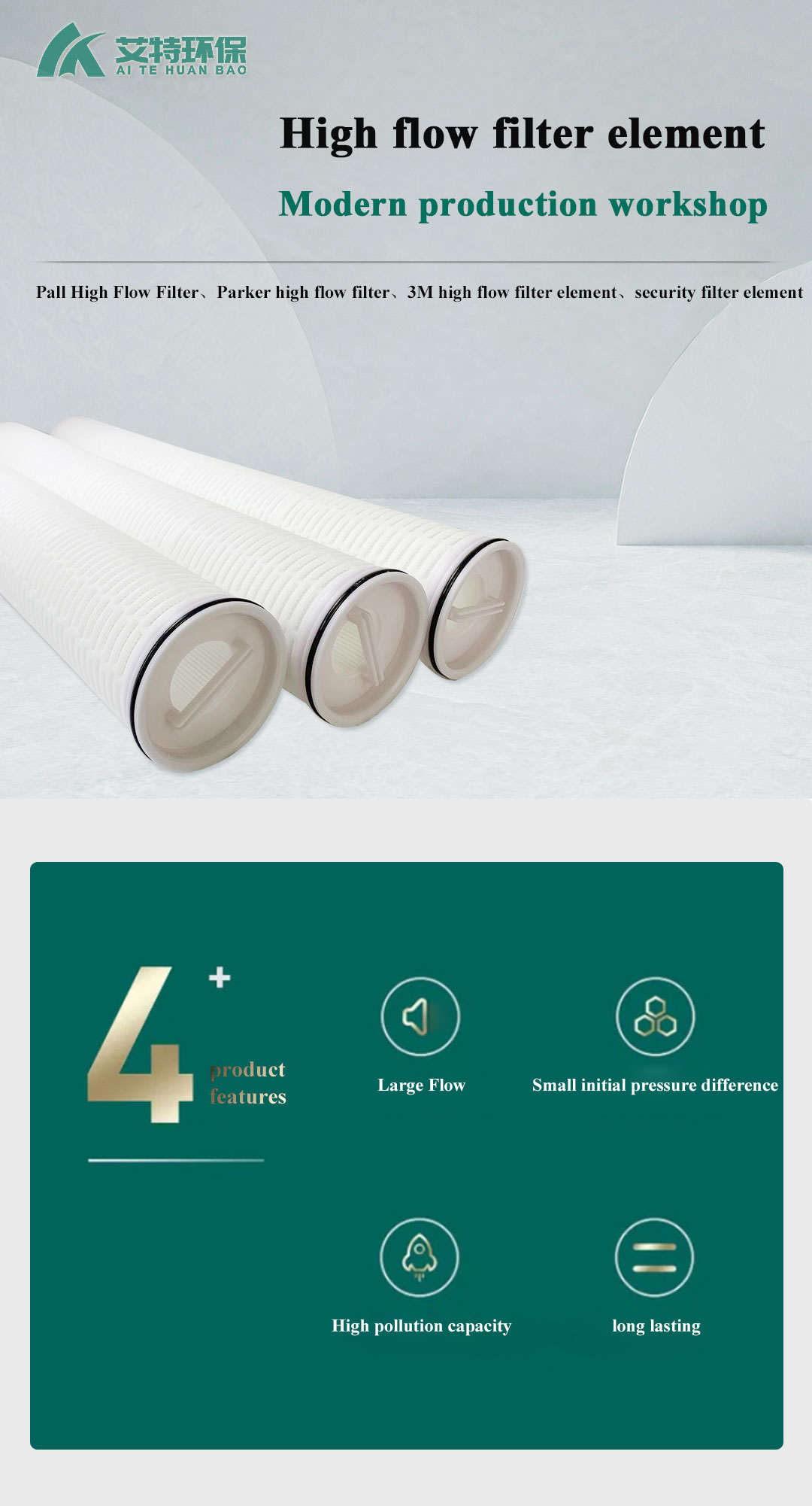

The single flux of large flow filter can be up to 70m3/h. Compared with the ordinary filter, it can greatly reduce the number of filter elements and significantly reduce the size of the supporting shell, so the initial investment cost is greatly reduced compared with the ordinary filter system

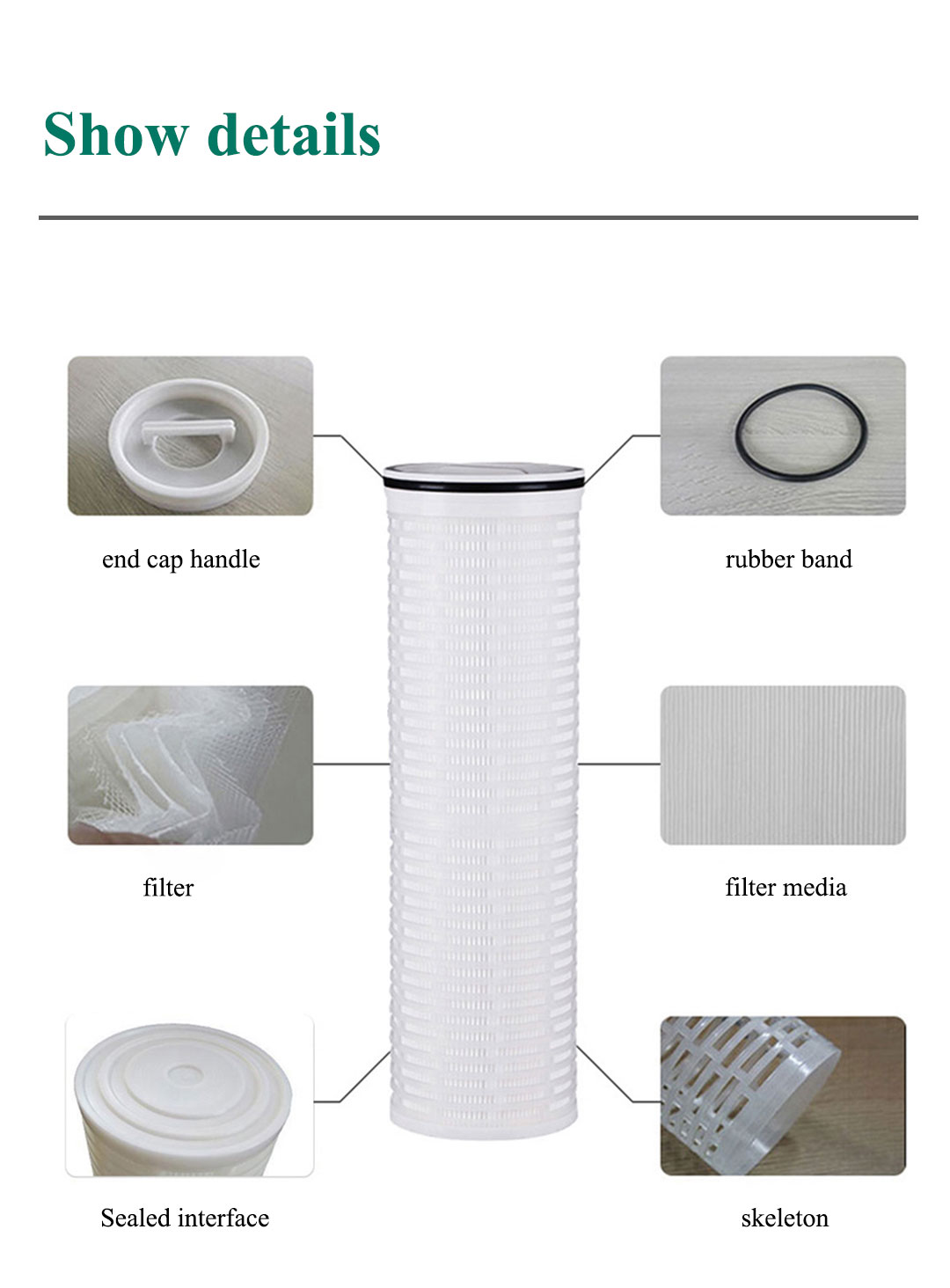

Large flow filter single core flux up to 70m3/h, compared with the ordinary filter element, can greatly reduce the number of filter element use, and significantly reduce the size of the supporting shell, so the initial investment cost than the ordinary filter system is greatly reduced to obtain the special folding design technology, so that the pressure drop is significantly lower than other filter element service life is 2-4 times more than the ordinary filter element. The convenient handle on the filter element significantly reduces the later replacement cost, making the replacement of the filter element simple and convenient. It can provide four kinds of filtration accuracy, respectively 0.5, 1, 5, 10 µm, to meet the requirements of different precision levels of the overall polypropylene design and hot melt bonding treatment, effectively prevent the secondary pollution of its own framework, enhance the pressure resistance of the filter element during the use of O-ring, To ensure the tightness and reliability of filtration surface filtration and deep filtration combined, so as to reduce the volume of the filter and save the cost, the product has the characteristics of low pressure difference, high contaminant capacity, in the use of filtration to reduce the number of filter element replacement and do not lose, so as to improve the work efficiency.

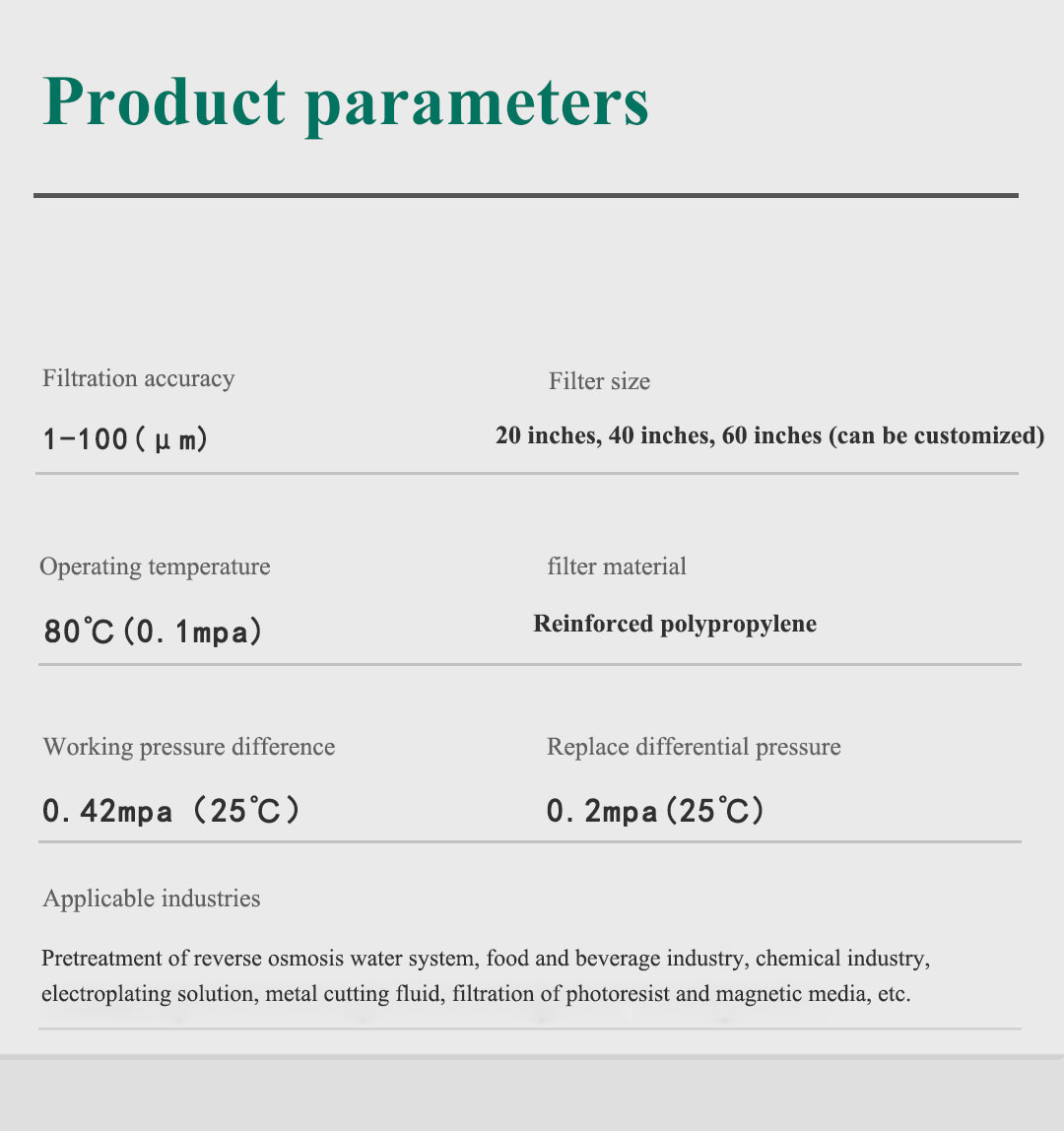

Maximum operating pressure: 3.5kg/cm2

Maximum operating temperature: 80℃

Recommended flow rate: 50m3/hr

Material: PP polypropylene

Od: 6 inches (152.4mm)

Length: 40 inches (1016mm), 60 inches (1524mm) optional

Sealing ring material: E-EPDM rubber, N-sodium butadiene rubber, S-silicone, V-fluorine rubber, T-PFA sealing fluorine rubber

1, the shape is stable, the impact resistance and alternating load capacity is better than other metal over materials;

2, good air permeability, stable separation effect;

3, excellent strength, suitable for high temperature, high pressure and strong corrosive environment;

4, especially suitable for high temperature gas filtration. Why is the large flow filter better than the ordinary filter? Sintered metal mesh is a multilayer metal woven wire mesh, through the process of laminated pressing and vacuum sintering. Each layer of mesh mesh interlace, forming a uniform and ideal filtering structure, overcome the common wire mesh low strength, poor rigidity, mesh shape instability of the insufficient shortcomings, the cleanliness of the equipment control elasticity is small, so as to be able to material pore size, permeability and strength characteristics of reasonable matching and design, It has accurate filtration precision, filtration impedance, mechanical strength, wear resistance, heat resistance and processability, so that the filtering effect is easy to control, and then as an ideal large flow filter element is widely used

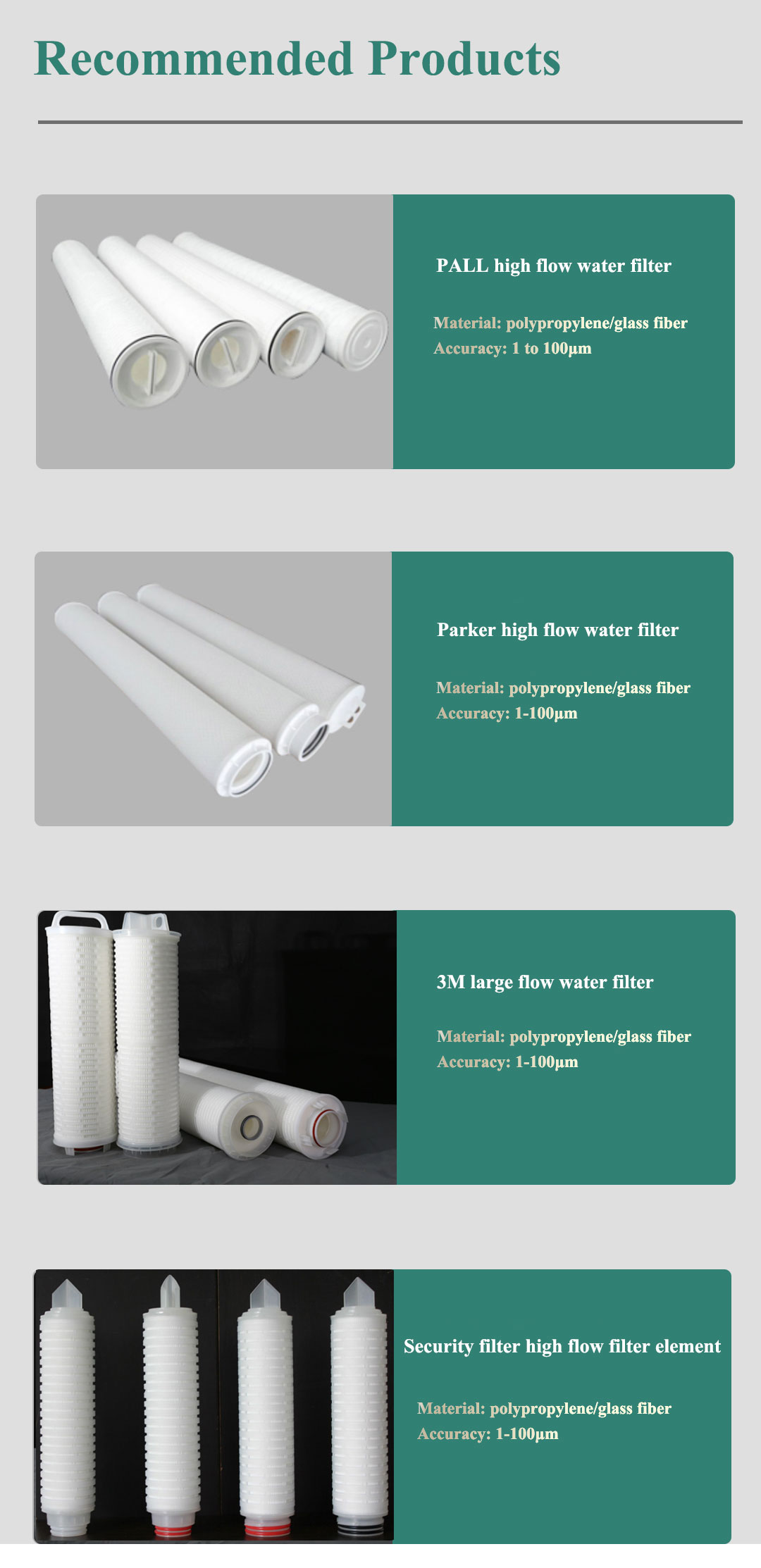

Oil filtration,

Chemical raw materials,

Organic solution filtration,

Electroplating bath filtration,

All kinds of water treatment,

Reverse osmosis pre-filtration,

Electronics industry, etc.

Large flow filter element

Similar ProductsVIEW MORE >