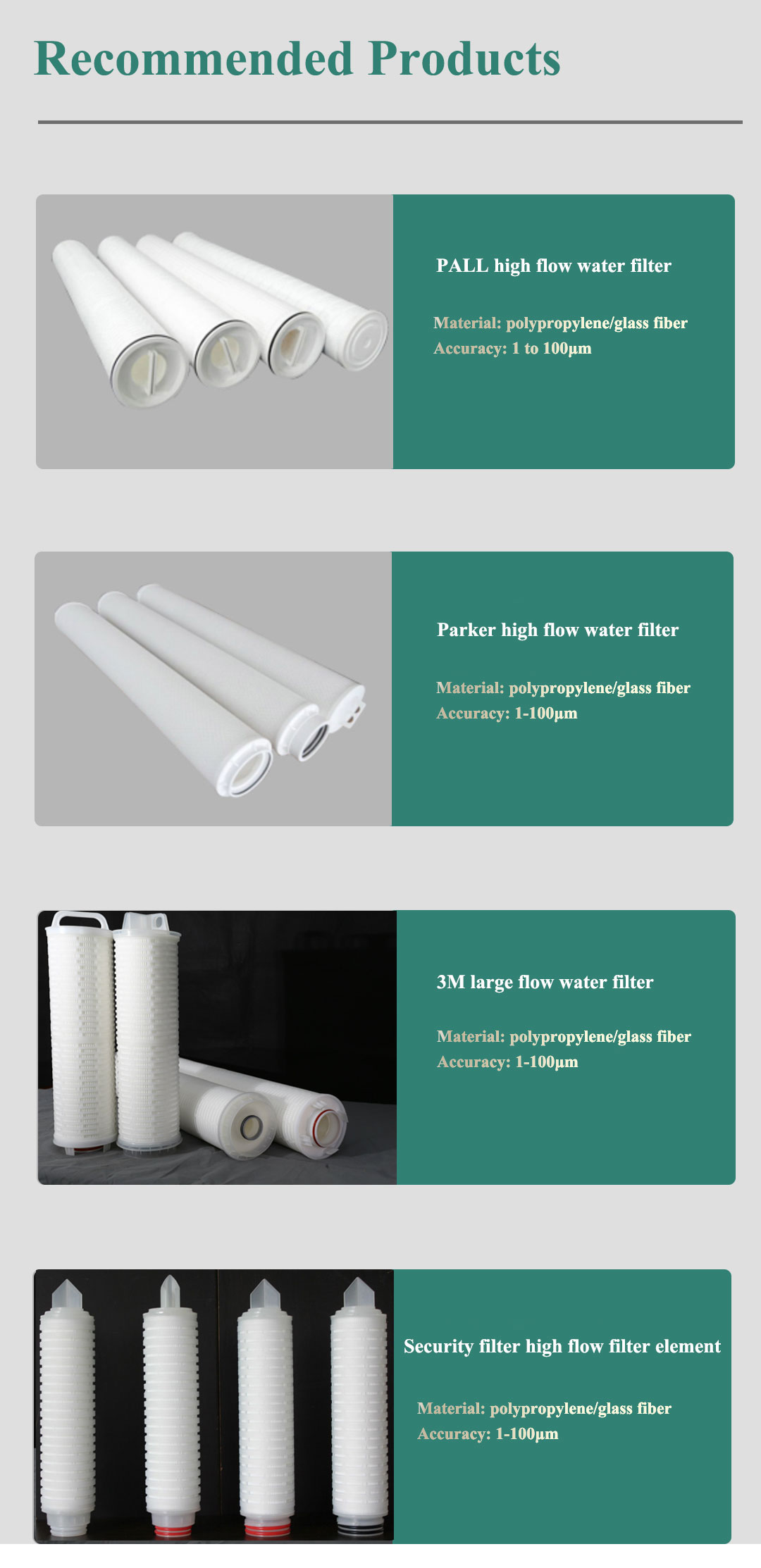

3M filter element is made of imported polyester fiber cloth filter material, which has durable performance. The filter medium, center rod and end cover are glued together as a whole. Because it is a folding design, compared with other filter elements to provide a larger filter area, longer filter life, reduce the number of filter updates, reduce the cost of filtration, from the point of view of industrial value is an economic filter product.

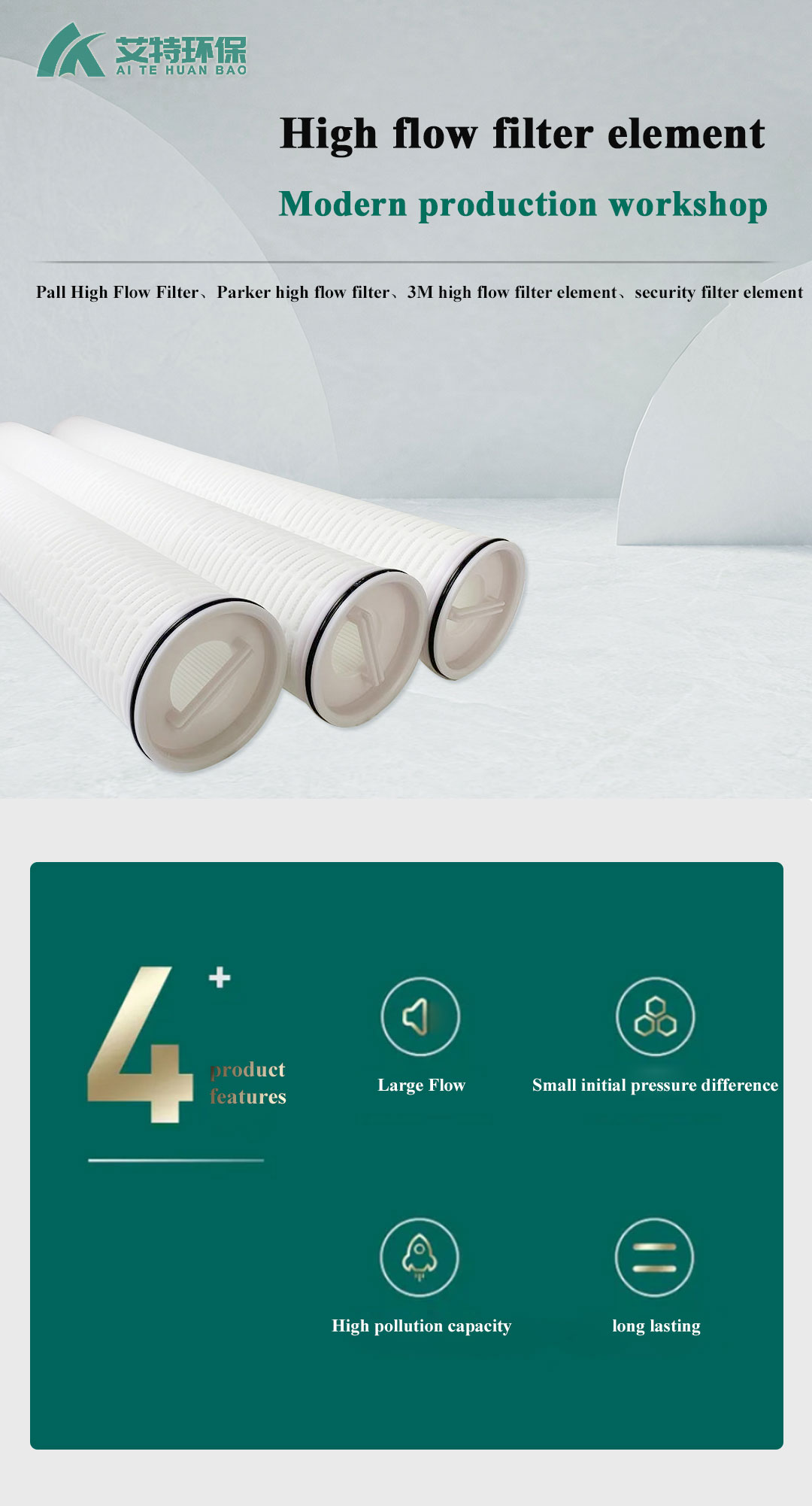

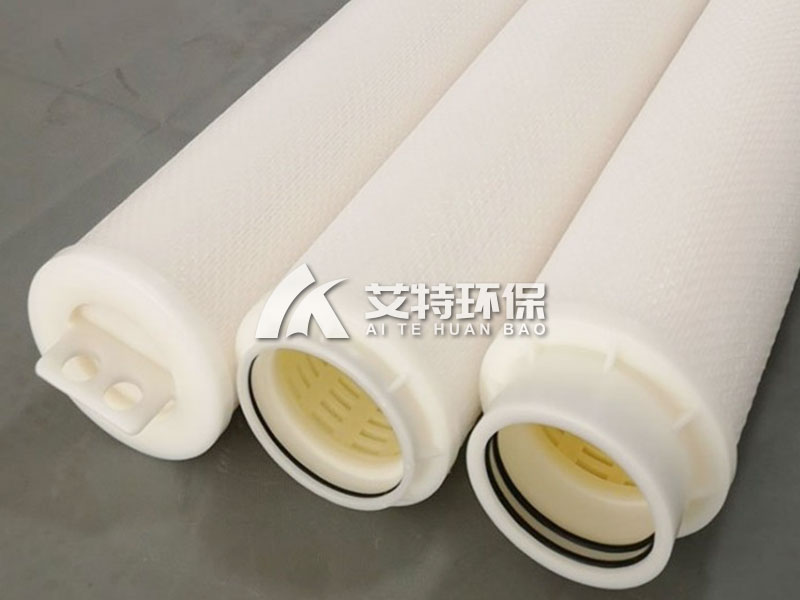

Large flow filter adopts deep fine polypropylene or glass fiber film as filter material, adopts pleating technology, and has a large diameter, flow is 20 times of the conventional filter. Liquid flow according to the actual working conditions, there are two forms: one is the inward and outward liquid flow, all the pollutants and impurities are intercepted in the filter element, reduce the precipitation of pollutants in the filter. The other is the liquid flow from outside to inside. All the pollutants and impurities are intercepted outside the filter element and can be discharged through the filter's blowdown valve. Because of its super-large flow design, so that in the same flow application, the use of filter element and filter is significantly reduced, saving the equipment input cost and labor cost.

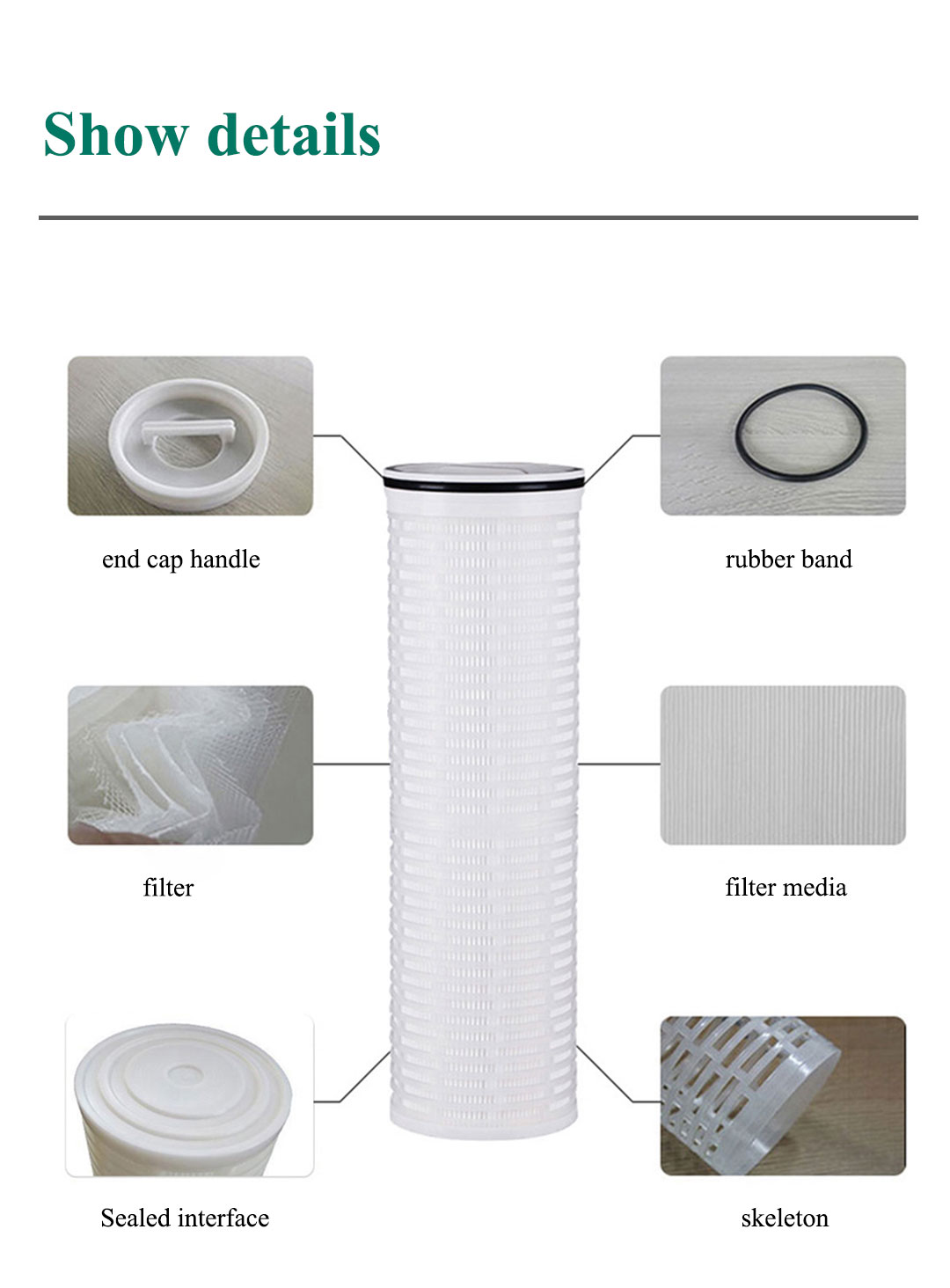

1. The membrane adopts folding deep structure, and the membrane filtration area is large; The high porosity deep long fiber layer filtration structure has good compression resistance.

2. Scientific design of multi-layer gradient aperture filtration structure, so that the filter element has the characteristics of high contaminant capacity, thus extending the service life of the filter element, saving the cost of users;

3. High filtration accuracy, can effectively filter microorganisms, suspended solids, particles, rust and other impurities in the liquid, the impurity interception efficiency is greater than 98%;

4. The filter element bears high filtration pressure;

5. The reasonable structure makes the filter element have a higher capacity of absorbing pollution;

6. The interface at both ends of the filter element adopts infrared hot melt welding, with higher strength and excellent sealing;

7. The use of 4mm thick PP high strength skeleton, can effectively alleviate the pressure difference caused by the filter element flattened phenomenon.

RO security filtration, urgent cold water, desalinated water, reuse water filtration; Seawater desalination pretreatment

Urban water and waste water recycling;

Power plant boiler supply water, condensate filter

Biological, chemical industry API, solvent, water filtration

Bottled water, food liquid, edible oil, juice, soft drinks, milk filtration

Electronic industry pure water, ultra-pure water

High flow folding filter HF40PP005A01

Similar ProductsVIEW MORE >