Pleated cartridge filter consists of a filter cartridge as a filter element or a filter with pulse injection. According to the installation method, the filter can be divided into inclined insert type, side loading type, lifting type and jacket type.

Pleated cartridge filter consists of a filter cartridge as a filter element or a filter with pulse injection. According to the installation method, the filter can be divided into inclined insert type, side loading type, lifting type and jacket type. According to the filter barrel material, it can be divided into long fiber polyester filter barrel filter, composite fiber filter barrel filter, anti-static filter barrel filter, flame retardant filter barrel filter, coated filter barrel filter, nano filter barrel filter, etc.

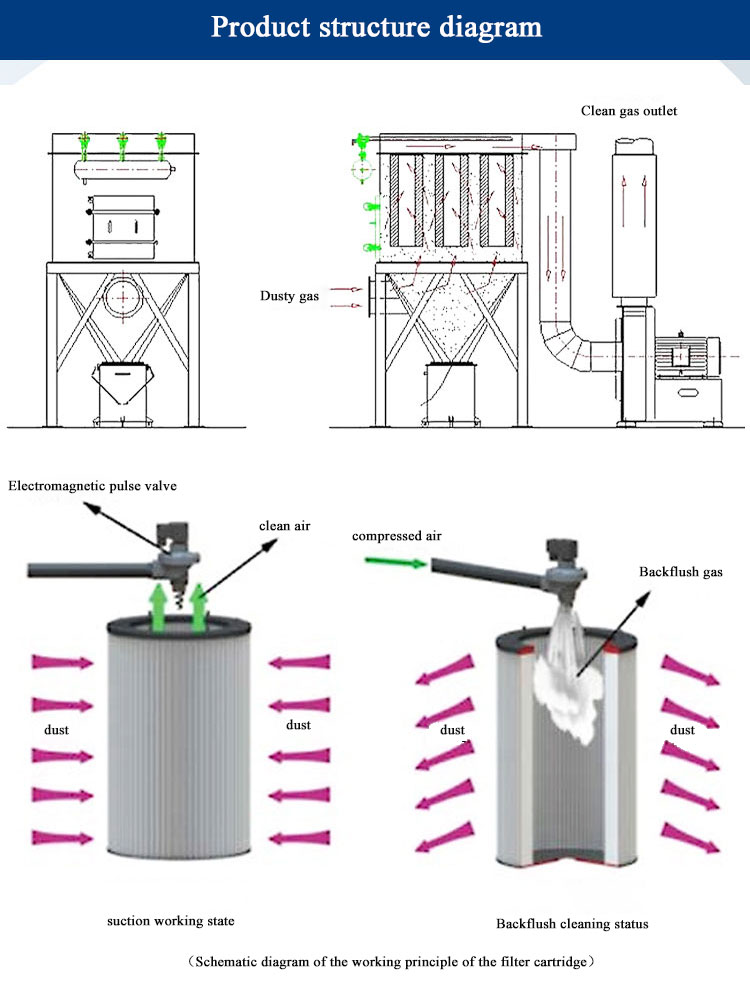

The structure of the pleated filter barrel dust collector is composed of air inlet pipe, air exhaust pipe, box, ash hopper, dust removal device, diversion device, air distribution plate, filter barrel and electronic control device, which is similar to the air box pulse bag dust removal structure.

After the dust-bearing gas enters the dust hopper, due to the sudden expansion of air flow section and the action of air flow distribution plate, some coarse particles in the air flow settle in the dust hopper under the action of dynamic and inertial forces. After the dust particles with fine particle size and small density enter the filter dust chamber, the dust is deposited on the surface of the filter material through the combined effect of Brown diffusion and screening, and the purified gas enters the clean gas chamber and is discharged by the exhaust pipe through the fan.

Widely used in metallurgy industry steel blast furnace dust removal system, building materials industry, electric power, chemical industry, carbon black, asphalt concrete mixing, boiler, flue gas dust removal and other industries of dust management and material recovery.

Pleated cartridge filter

Similar ProductsVIEW MORE >