Bin top cartridge dust collector is a dust collector used in the top of silo, this dust collector is mainly used in cement silo top, asphalt mixing station silo top, grain silo top, limestone silo top, concrete silo top and other industries of silo top dust removal.

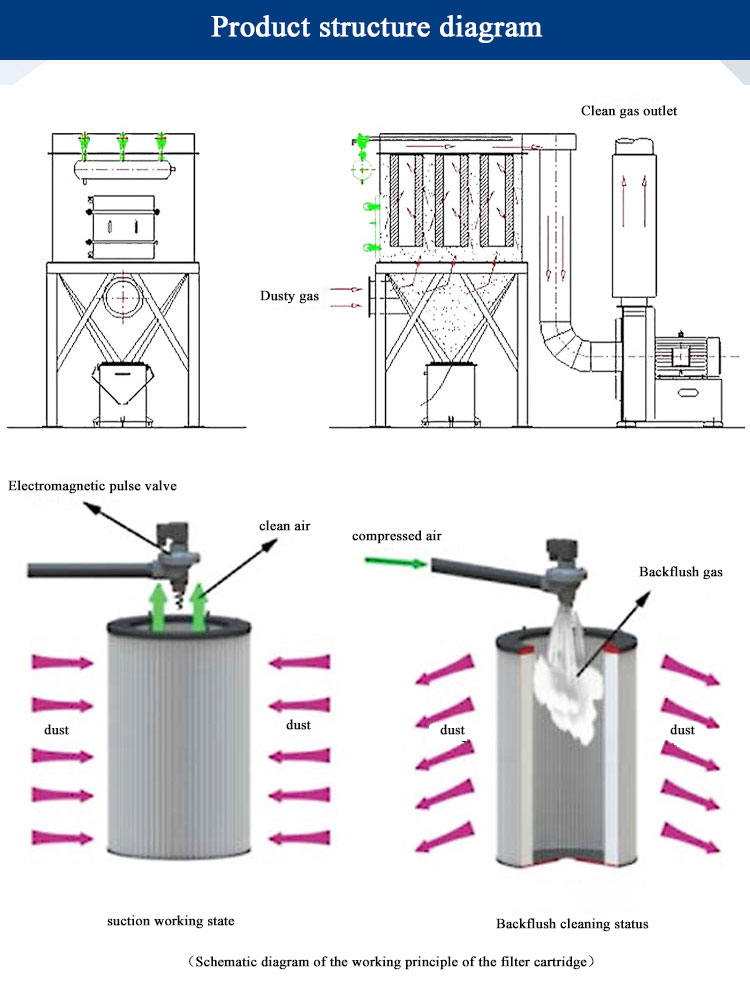

Bin top cartridge dust collector is a dust collector used in the top of silo, this dust collector is mainly used in cement silo top, asphalt mixing station silo top, grain silo top, limestone silo top, concrete silo top and other industries of silo top dust removal. It can filter fine, non-fibrous dry dust in the gas, and can be recycled materials directly into the warehouse. The structure of the bin top filter is mainly composed of dust removal box, filter cylinder, control cabinet, electromagnetic pulse valve, injection device, ladder guardrail, induced draft fan and so on.

The dust-containing gas enters the box of the dust collector through the air inlet, and the fine dust particles are delayed on the outer wall of the filter cylinder due to various effects of the filter cylinder. The purified gas is discharged through the outlet of the box on the filter cylinder. With the increase of using time, the adsorption of dust on the surface of the filter cylinder increases, the permeability of the filter cylinder is weakened, and the resistance of the dust collector is increased.

In order to control the resistance of the dust collector within the limited range, the control cabinet sends out a signal and opens the electromagnetic pulse valve successively, so that the compressed air in the air bag is sprayed to the corresponding Venter tube (called the primary air) through each hole of the Venter tube, and induces the surrounding air several times more than the primary air (called the secondary air) into the filter cylinder when the high-speed air flows through the Venter tube, resulting in rapid expansion between the filter cylinders.

As the impact of the reverse pulse air flow soon disappears, the filter cylinder shrinks sharply, so that the dust accumulated on the outer wall of the filter cylinder is cleaned up. The falling dust goes into the ash vault.

1, the use of pleated filter cylinder dust removal, increase the density of the cylinder arrangement, so that the dust collector in the structure is relatively compact, small footprint.

2, high dust removal efficiency, generally can reach more than 95%, simple maintenance and operation.

3,The folding ends of the filter barrel are sealed tightly, which reduces the air leakage rate of the dust collector.

4, easy to replace the filter cylinder, shorten the parking time.

Bin top cartridge dust collector

Similar ProductsVIEW MORE >