The filter barrel dust collector is a kind of professional dust collector equipment, specially to solve some problems such as difficult dust collection, poor filtering effect, high filtering wind speed, dust removal is not easy, so that the dust collector equipment in the operation cost and dust removal effect has been double improved

The filter barrel dust collector is a kind of professional dust collector equipment, specially to solve some problems such as difficult dust collection, poor filtering effect, high filtering wind speed, dust removal is not easy, so that the dust collector equipment in the operation cost and dust removal effect has been double improved. There are two traditional cleaning methods of the filter barrel dust collector, one is the high pressure air back blowing, the other is the pulse air jet.

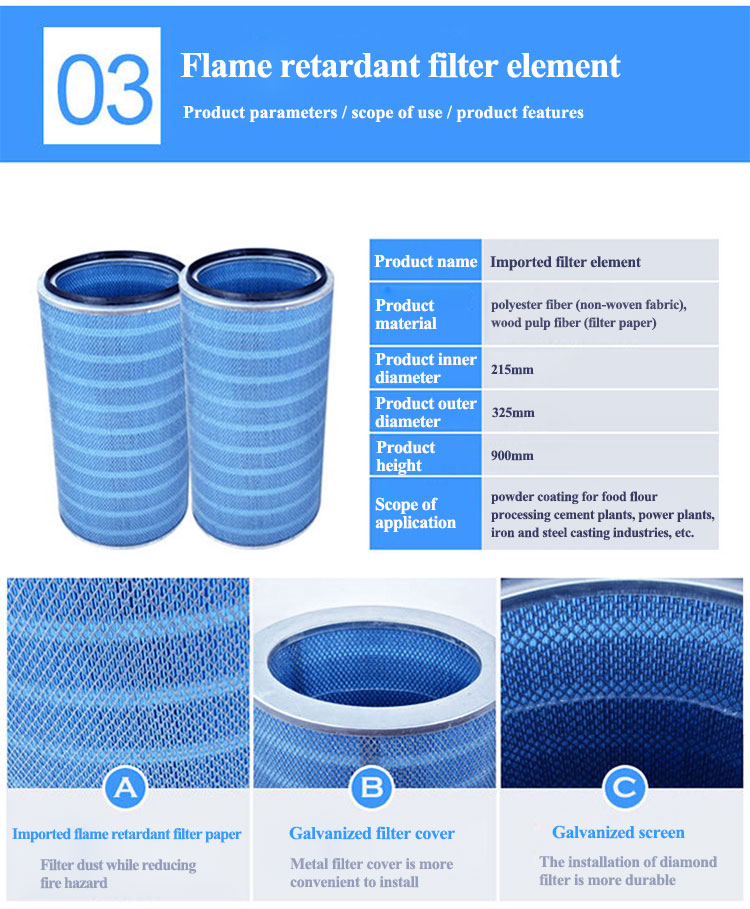

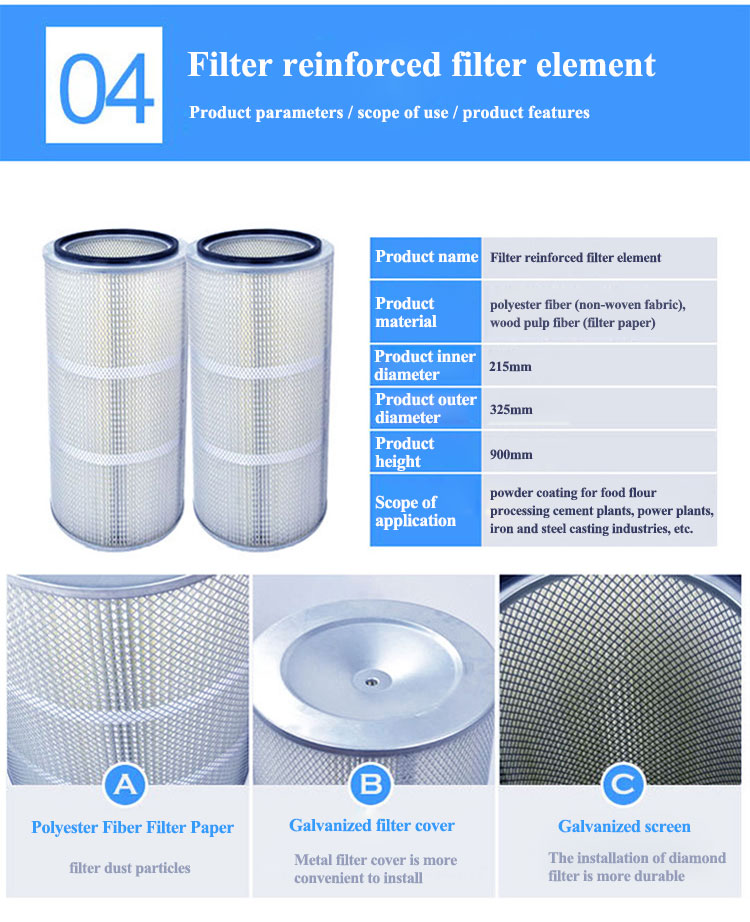

The end cover of the filter cylinder is carbon steel

Material: gaoxiao air filter paper

Skeleton: punched plate, diamond mesh

Filtration accuracy: 10um

Service life: about 2000h

1.The structure of the drum type dust collector is composed of air inlet pipe, air exhaust pipe, box, ash hopper, dust removal device, diversion device, air distribution plate, filter cylinder and electronic control device, similar to the structure of the air box pulse bag type dust collector.

2.The arrangement of the filter cylinder in the dust collector is very important. It can be arranged vertically on the box flower plate or tilted on the flower plate. From the view of the dust removal effect, the vertical arrangement is more reasonable. The lower part of the flower plate is the filter chamber, and the upper part is the gas box pulse chamber. A airflow distribution plate is installed at the inlet of the dust collector.

3.After the dust-bearing gas enters the dust hopper, due to the sudden expansion of air flow section and the action of air flow distribution plate, some coarse particles in the air flow settle in the dust hopper under the action of dynamic and inertial forces. After the dust particles with fine particle size and small density enter the filter chamber, the dust is deposited on the surface of the filter bag through the combination effect of bag diffusion and screening, and the purified gas enters the clean gas chamber and is discharged by the exhaust pipe through the fan.

4.The resistance of the cartridge filter increases with the increase of the dust layer thickness on the filter bag surface. When the resistance reaches a specified value, the ash is cleaned. At this time, the PLC program controls the opening and closing of the electromagnetic pulse valve, the first chamber lifting valve is closed, the filter air is cut off, and then the electromagnetic pulse valve is opened, the compressed air and a short time in the upper box rapidly expanded, into the filter cylinder, the filter cylinder expansion deformation vibration, and under the action of the reverse airflow scour, the dust attached to the outer surface of the filter bag is stripped into the ash bucket. After the cleaning is completed, the electromagnetic pulse valve is closed, the lifting valve is opened, and the chamber is restored to the filtering state. The cleaning room is carried out in turn, from the ** room cleaning to the next cleaning is a cleaning cycle. The falling dust falls into the ash hopper and is discharged by the ash valve.

5.Filter filter has a high application rate in tobacco, medicine, mechanical processing, food, metallurgy, chemical industry, hardware processing, building materials, light industry, electronics, pharmacy and so on.

Widely used in food, pharmaceutical, feed, metallurgy, building materials, cement, machinery, chemical, electric power, light industry dust gas purification and dust material recovery.

Dust cylinder dust collector

Similar ProductsVIEW MORE >