What is the cause of the filter dust leakage?

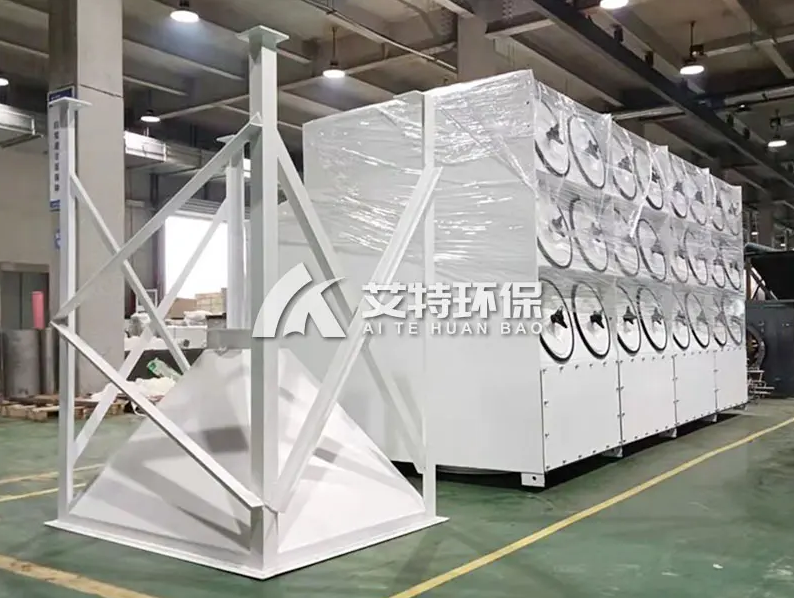

The structure of the filter is composed of air inlet pipe, exhaust pipe, box body, ash hopper, dust removal device, guide device, air distribution plate, filter cylinder, etc. After the dust-bearing gas enters the dust collector, some coarse particles in the air flow settle in the dust hopper under the action of dynamic and inertial forces due to the sudden expansion of air section and the action of air distribution plate. After the fine particles and small density dust particles enter the dust filtration chamber, the dust is deposited on the surface of the filter material. The purified gas enters the gas purification chamber and is discharged from the exhaust pipe through the fan.

Cylinder dust collector is a dust removal device. Dust precipitator exhaust pipe outlet once found, dust discharge is large, exceed the standard. In this case, there is a continuous discharge of dust gas at the exhaust outlet. This phenomenon is usually due to filter material damage, the upper lifting port and the top of the shell joint cleaning is not standard or seal treatment caused by poor. This condition is dusty air in a short period of time or instant discharge. In this case, the use time of the filter material is too long or part of the filter material is damaged, but the impact is small. Therefore, the dust - containing air flow will be expelled in a short time during the pulse injection process.

The reason for the dust exposure of the filter cylinder is that the outlet of the filter cylinder continues to "dust", that is, the filter cylinder is seriously damaged, the filter cylinder pressure plate is loose or the upper and lower lifting port of the filter cylinder is loose, and the upper lifting port and the flower plate are loose. The cylinder dust collector instantly "discharges ash". In this case, although the dust removal filter cylinder is damaged, it is not very serious. There will be instantaneous "fly ash" in the spray process of the filter cylinder. The upper box of the filter cylinder is assembled by the air purification chamber and the ash bucket. The inspection door is connected with the upper box and the ash bucket by screw connection or welding connection. If the sealing strip is added during the connection operation or the sealing strip is unqualified, dust leakage will occur. The filter material of cylinder dust collector is generally divided into normal temperature and high temperature. The normal temperature wind speed is controlled between 1.0-2.0, and the high temperature wind speed is controlled between 0.8-1.0. If the wind speed is too high, the dust will form a strong adhesion on the surface of the filter material. After pulse ejection, dust will rapidly adhere to the surface of the filter material, increase the resistance of the dust removal equipment, resulting in dust leakage.

When the above situation occurs, the cartridge dust collector should be treated in time. In any case, it should be cleaned. If the phenomenon of ash leakage is still not solved, it indicates that the filter material has been basically damaged, it is recommended to change all the filter material. When determining which cartridge is at fault, the appropriate cartridge can be used while the pulse controller is operating. If more than 2/3 of the cartridges are damaged or blocked, replace all cartridges. When changing, the dust collector needs to stop working, and the filter cartridge is connected by the chuck. When disassembling, unscrew the filter cartridge in the opposite direction, clean the dust on the top cover, and replace the composite size of the filter cartridge.